[/url]

[/url]The future

- tegfan railway

- Trainee Fireman

- Posts: 133

- Joined: Sun Dec 12, 2010 12:28 pm

- Location: 222

The future

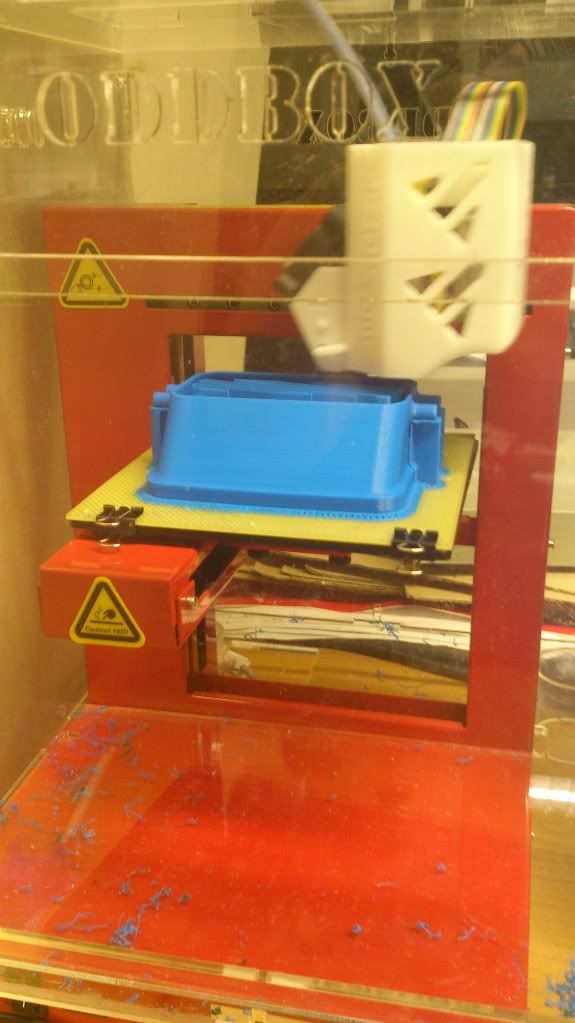

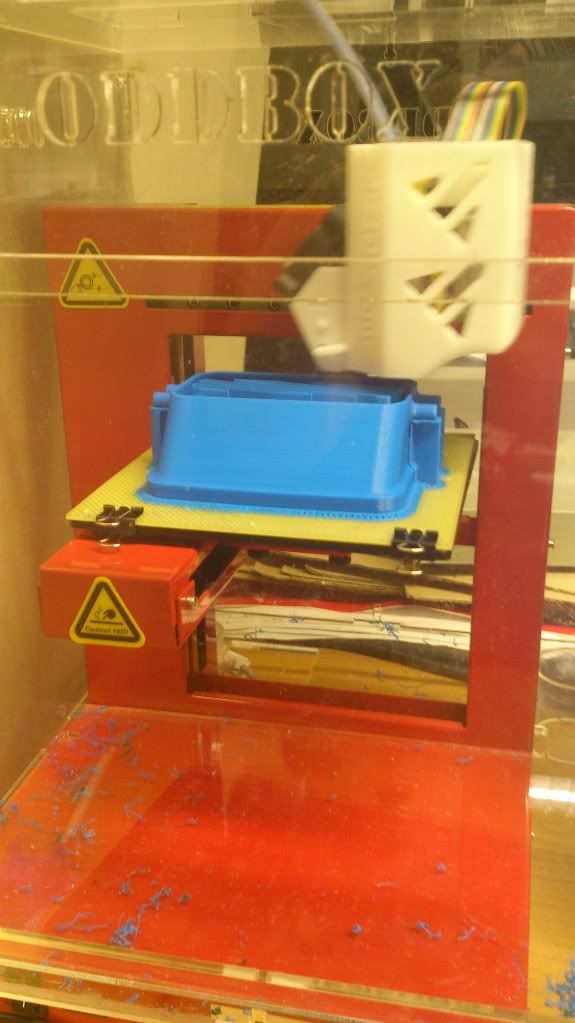

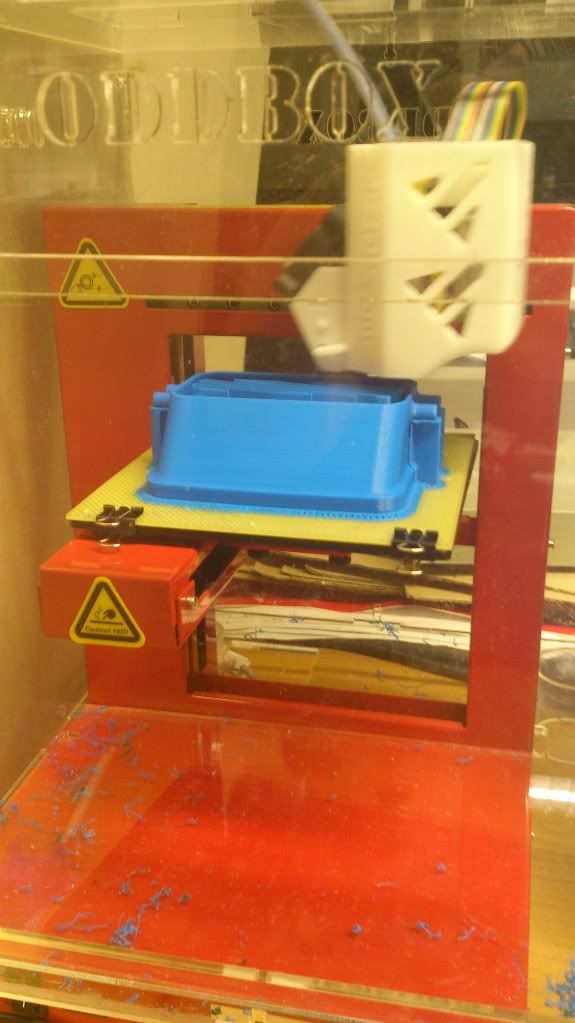

I remember when watching Star Trek as a kid I used to marvel at the idea of a replicator. Whilst not being the Trekkies dream a 3d printer goes some way towards the goal of a working replicator. I am fortunate as a teacher of product design, I have access to a number of CAM machines, one of which is a 3d printer. I had a couple of ideas in my head on how to use it in relation to garden railways. Anyway to cut a long story short I came across a website called Thingiverse. Here you can find STL files for all sorts of things ready to download and print using the 3d printer. Amongst these model I found a Hudson Tipper. The bucket is printing as I am typing, frame and othe parts will be done tomorrow. The downloaded model comes in 45mm but can be easily modded to 32mm for my railway.

[/url]

[/url]

[/url]

[/url]- tegfan railway

- Trainee Fireman

- Posts: 133

- Joined: Sun Dec 12, 2010 12:28 pm

- Location: 222

- tegfan railway

- Trainee Fireman

- Posts: 133

- Joined: Sun Dec 12, 2010 12:28 pm

- Location: 222

Was wondering how long it would be before somebody started doing designs for 16mm scale rolling stock to be 3D printed. The results look pretty good, looks like the surface finish is a bit better then I would have expected for a Fused Deposition Modelling machine.

"What the hell is that?"

"It's a model icebreaker sir."

"It's a bit big isn't it?"

"It's a full scale model sir....."

"It's a model icebreaker sir."

"It's a bit big isn't it?"

"It's a full scale model sir....."

- MDLR

- Driver

- Posts: 4027

- Joined: Thu Jan 15, 2009 10:38 pm

- Location: Near Ripley, Derbyshire, UK

- Contact:

Are you aware of PVMR? http://www.pvmr.co.uk/home/4578077269 You wouldn't have seen his stuff at Peterborough......................laalratty:100830 wrote:Was wondering how long it would be before somebody started doing designs for 16mm scale rolling stock to be 3D printed. The results look pretty good, looks like the surface finish is a bit better then I would have expected for a Fused Deposition Modelling machine.

Last edited by MDLR on Thu May 22, 2014 1:56 pm, edited 1 time in total.

- Dannypenguin

- Trainee Driver

- Posts: 632

- Joined: Tue Feb 26, 2013 9:57 am

- Location: Forest of Dean, UK

- Contact:

I was talking to PVMR at Peterborough and he uses a different type of printing - he told us he uses a dutch company who (basically) have a bucket of dust and fire a laser into it, hardening the dust into a solid. It means virtually everything can be created in on printing  Quite a good idea really!

Quite a good idea really!

Dan

Visit the PFLR website - http://poultonfarmlightrailway.webs.com/

Dean Forest Railway Society website - http://dfrsociety.org/

Visit the PFLR website - http://poultonfarmlightrailway.webs.com/

Dean Forest Railway Society website - http://dfrsociety.org/

Strange, I put a reply to this yesterday... I've got two PVMR slate waggons, however he manufactures his own kits, whereas I believe this is the first time to my knowledge that someone has put a design on the internet to be printed out at home.MDLR:100832 wrote:Are you aware of PVMR? http://www.pvmr.co.uk/home/4578077269 You wouldn't have seen his stuff at Peterborough......................laalratty:100830 wrote:Was wondering how long it would be before somebody started doing designs for 16mm scale rolling stock to be 3D printed. The results look pretty good, looks like the surface finish is a bit better then I would have expected for a Fused Deposition Modelling machine.

"What the hell is that?"

"It's a model icebreaker sir."

"It's a bit big isn't it?"

"It's a full scale model sir....."

"It's a model icebreaker sir."

"It's a bit big isn't it?"

"It's a full scale model sir....."

- tegfan railway

- Trainee Fireman

- Posts: 133

- Joined: Sun Dec 12, 2010 12:28 pm

- Location: 222

- robc_wa

- Trainee Fireman

- Posts: 106

- Joined: Wed Jun 08, 2011 11:41 am

- Location: Perth, Western Australia

I must say that this looks excellent. However........what is the cost of the material relative to say buying an injection moulded kit? I know its not all about cost but I did just wonder.

Whilst on the material how well do you think it will take paint and will the wheels be too soft for much running?

The cost of the machines seem to be coming down, there was one in my local Officeworks at about $1300 the other day, which I think compares favorably with a small format laser cutter.

Whilst on the material how well do you think it will take paint and will the wheels be too soft for much running?

The cost of the machines seem to be coming down, there was one in my local Officeworks at about $1300 the other day, which I think compares favorably with a small format laser cutter.

- tegfan railway

- Trainee Fireman

- Posts: 133

- Joined: Sun Dec 12, 2010 12:28 pm

- Location: 222

Cost of the material ABS in this case was £13 for a KG of filament so quite a few wagons. ABS takes paint well and can also be fettled with files or wet and dry. In terms of wheels I will either use steel ones from Swift Sixteen or Resin from Andel. Not convinced that ABS will up to the job of wheels. Just for reference there is a Kickstarter 3D printer about to come out at $100!!robc_wa:100871 wrote:I must say that this looks excellent. However........what is the cost of the material relative to say buying an injection moulded kit? I know its not all about cost but I did just wonder.

Whilst on the material how well do you think it will take paint and will the wheels be too soft for much running?

The cost of the machines seem to be coming down, there was one in my local Officeworks at about $1300 the other day, which I think compares favourably with a small format laser cutter.

Who is online

Users browsing this forum: No registered users and 2 guests