Page 2 of 3

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Thu Feb 18, 2021 2:33 pm

by ge_rik

GTB wrote: ↑Thu Feb 18, 2021 10:14 am

More poor design than poor plastic, although recycled plastic won't help. I've repaired a few electronic device cases over the years with the same problem of the screw pillars cracking, but I've also got a couple designed so that they'll never crack.

I use pieces of brass tube as a collar pressed on over the split post as a repair. The tube needs to be a tight enough push fit to close the crack in the plastic and it won't work if any chunks of plastic have broken away from the post.

The repair will last, but only if you are careful about tightening up the screws, as the self tappers used can easily strip out the thread in plastic if over tightened.

Past that stage, unfortunately. Most of the pieces of the various pillars have parted company and either disappeared or are rattling around inside the clamshell.

GTB wrote: ↑Thu Feb 18, 2021 10:14 am

The loco body has come up nicely, but I agree, it needs a dummy frame behind the cylinders and from there to the front headstock. There's far too much daylight under the front at present.

The dummy frame is now done and, as on the Lyn, serves a triple purpose of filling the space, retaining the cylinder moulding and securing the body to the motor block..

I'll post a few photos later.

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Feb 22, 2021 12:56 pm

by ge_rik

On the home straight ........

(Images hosted on my blog -

https://riksrailway.blogspot.com/2021/0 ... rt-88.html )

There's still a bit more to be done - a bit more pipework, nameplates, numberplates, makers' plates and some gauges, pipes and brake standard in the cab. She seems to run quite well but I've not had a chance to do a full test run as yet.

3 x 18650 li-ion cells, Deltang Rx65c receiver/controller and MyLocoSound Universal steam soundcard.

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Feb 22, 2021 1:54 pm

by Peter Butler

That's looking really good Rik. You have managed to get a smooth paint surface too, very well done.

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Feb 22, 2021 5:12 pm

by philipy

Yes, I agree with Peter, a very nice job.

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Feb 22, 2021 6:12 pm

by ge_rik

Thanks chaps

I've now blogged the build here in case anyone wants to see wot I dun

https://riksrailway.blogspot.com/2021/0 ... -into.html

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Wed Feb 24, 2021 2:53 pm

by Andrew

That's a lovely-looking loco Rik - it will look equally at home at the head of a posh passenger rake or roughing it with a goods...

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sun Mar 07, 2021 1:31 pm

by Sylvian Tennant

Lovely work Rik. This CAD/3D print malarkey is certainly becoming very tempting.

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sun Mar 07, 2021 6:17 pm

by -steves-

Agree with what everyone else has said, great design, great build and excellent finish, very well done

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Mar 15, 2021 3:53 pm

by ge_rik

Update on progress

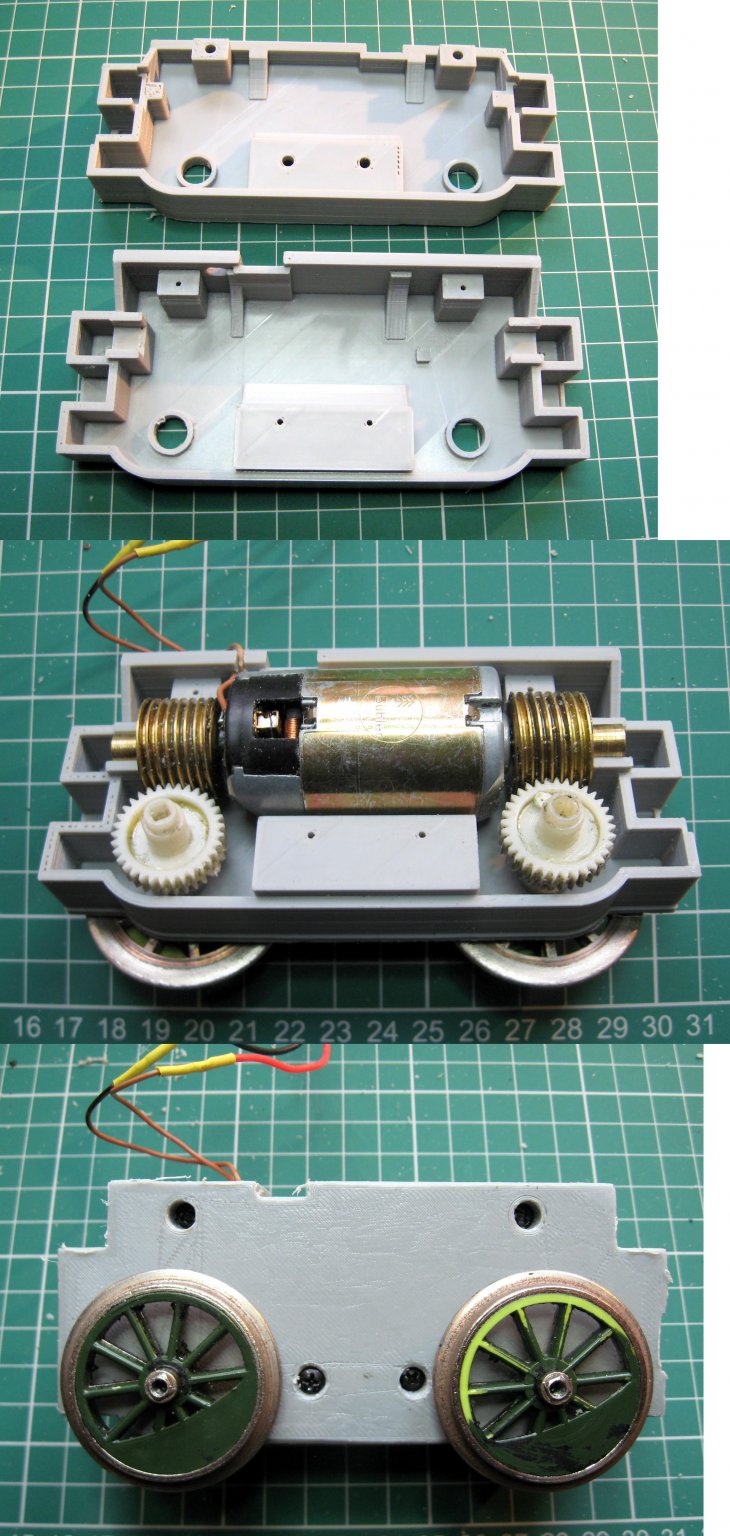

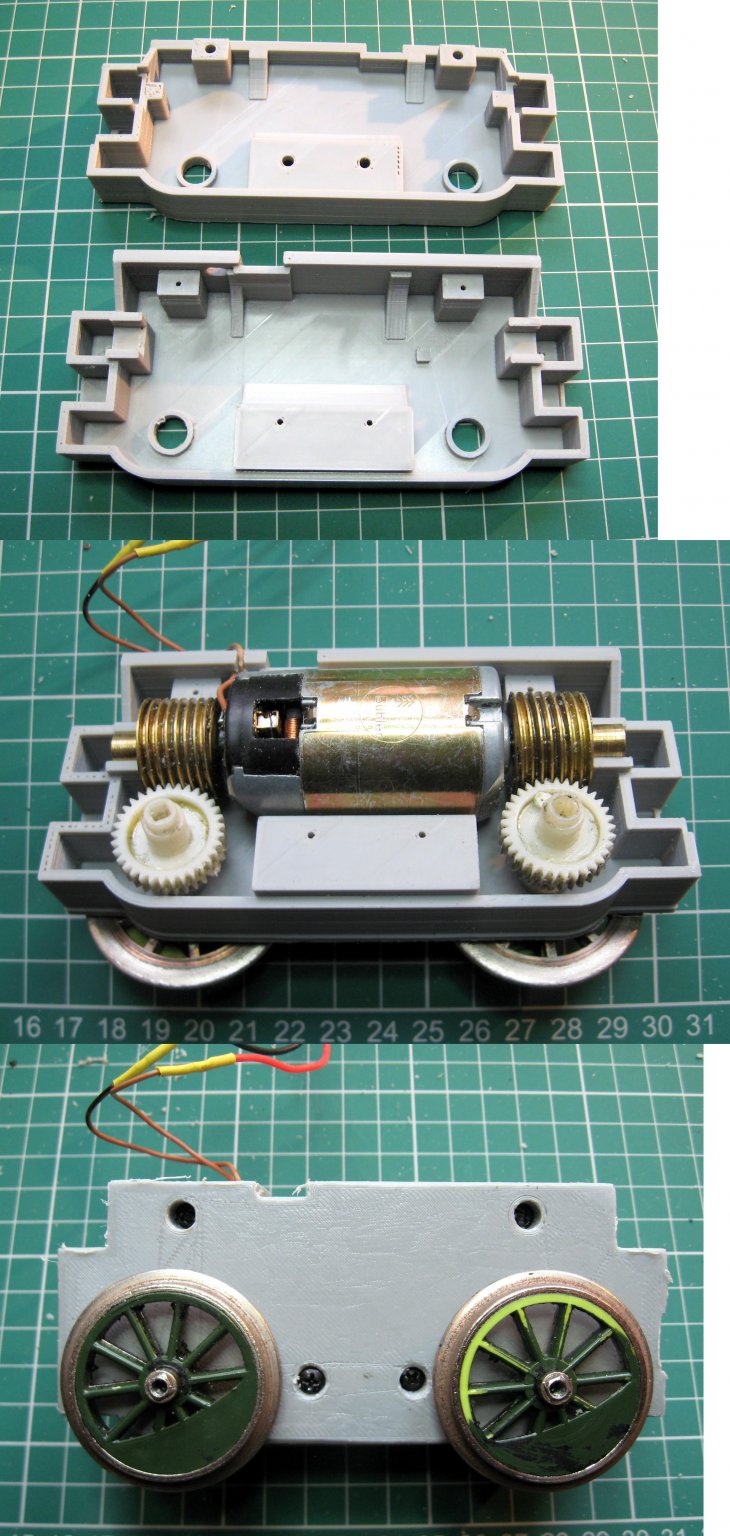

It's taken me a while - three or four re-designs plus a few duff prints - but at last I now have a purpose-made clamshell housing for the motor block to accommodate the larger motor which was installed by a previous owner.

I moved the axles out by a couple of mm to ensure the worm wheels were more central on the worms and also to make sure they couldn't rub against the motor casing as previously happened. It means I'll have to extend the connecting rods - but that's a small price to pay....

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Mar 15, 2021 4:10 pm

by Peter Butler

Now that's what 3D printing is for!

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Mar 15, 2021 4:30 pm

by philipy

Very nice job Rik.

I'm going to have to do something similar but starting from scratch, for my Wickham trolley. I just hope I can do as well.

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Mar 15, 2021 5:54 pm

by ge_rik

Peter Butler wrote: ↑Mon Mar 15, 2021 4:10 pm

Now that's what 3D printing is for!

My thinking exactly. It would be difficult to construct such a convoluted shape in any other way, methinks.

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Mon Mar 15, 2021 6:02 pm

by ge_rik

philipy wrote: ↑Mon Mar 15, 2021 4:30 pm

I'm going to have to do something similar but starting from scratch, for my Wickham trolley. I just hope I can do as well.

At least I had the original on which to base it. Starting from scratch would have made it twice (if not more) as difficult.

Something I found useful (eventually), was to draw the motor, worms and bearings as a unit and use it to check how well it fitted. With TinkerCAD, I could actually turn it into a "hole' which I then used to carve a motor shaped compartment inside the closed block. It means the real motor is a perfect fit - uncannily so ......

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Fri Mar 19, 2021 7:39 am

by ge_rik

And so the saga continues ......

After reassembling the loco, I gave her a test run. Still very disappointing in terms of pulling power. Even with a standard load of eight goods wagons the loco really struggled up my 1:40 gradients which my other locos gallop up. It also slowed appreciably on curves; the curve on the gradient brought it to a snail's pace on full power. I discovered the gauge on the drivers was slightly wide, but pushing the wheels tighter on to the gears to bring them to gauge made minimal difference. I stripped the motor block down to see if my clamshell was rubbing on anything. Nothing evident but I filed possible pinch points just in case. I reassembled and found there was very little improvement.

In desperation, I assembled a duplicate Lyn motor block which JimmyB has kindly sent me - which looks almost new.

Another test run and exactly the same outcome! Too little power to cope with a standard train!!

I can only assume that, for whatever reason, the large worms seriously impede the motor's ability to transmit power.

My next resort is to see if I can replace the worms with smaller diameter versions. I've ordered a gear puller and have found out how to calculate the mod value of the worm wheels. I just hope I can find a couple of replacements somewhere......

I will not be defeated!!

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Fri Mar 19, 2021 7:59 am

by ge_rik

According to this online calculator, it looks like it's a 0.5 mod gear on a 2.5mm shaft which is reassuring that it's not something obscure.

https://www.technobotsonline.com/gear-s ... lator.html

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sat Mar 20, 2021 8:41 am

by Jimmyb

Rik, I believe that the smaller worm is the solution, but I do not believe anybody has mentioned what the issue (apologies if you have and I have missed it), I think this is all to with "moments around a point".

The centre of the motor spindle is the fulcrum, and the motor provides the power which is a constant (assuming constant voltage input) the the further you move from the fulcrum, less load is required to equal the power output, ergo the larger the worm the less power drive you have.

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sat Mar 20, 2021 8:54 am

by ge_rik

Jimmyb wrote: ↑Sat Mar 20, 2021 8:41 am

Rik, I believe that the smaller worm is the solution, but I do not believe anybody has mentioned what the issue (apologies if you have and I have missed it), I think this is all to with "moments around a point".

The centre of the motor spindle is the fulcrum, and the motor provides the power which is a constant (assuming constant voltage input) the the further you move from the fulcrum, less load is required to equal the power output, ergo the larger the worm the less power drive you have.

Thanks Jim

That's exactly my thinking though as a former primary school teacher my explanations are far less eloquent. I was out on a walk with a mate (a former physics teacher) yesterday and I found the easiest way to explain it was to use my walking pole like a propeller. Much more effort was required to rotate it when my other hand was stopping it further away from the handle and much less effort when the resistance was closer to the handle.

My mate agreed with my practical demonstration and then explained it all with moments.....

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sat Mar 20, 2021 1:44 pm

by philipy

ge_rik wrote: ↑Sat Mar 20, 2021 8:54 am

then explained it all with moments.....

Blond ones?

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Sat Mar 20, 2021 6:37 pm

by ge_rik

philipy wrote: ↑Sat Mar 20, 2021 1:44 pm

ge_rik wrote: ↑Sat Mar 20, 2021 8:54 am

then explained it all with moments.....

Blond ones?

Melting ....

Rik

Re: Lyn >> Schull & Skibbereen Erin(ish)

Posted: Fri Jun 04, 2021 11:50 am

by FWLR

That is a blooming brilliant build Rik. You have mastered the art of this 3d printing stuff. Yes it is easy enough and the more you work on it, the easier it gets I have found, but I am still a marathon away from doing anything as brilliant as yours.

SUPBERB.....

PS I was looking for another emoji to say how brilliant it is, but it seems to have disappeared....