Page 10 of 46

Re: Llewellyn Loco Works #1

Posted: Fri Mar 30, 2018 10:00 pm

by tom_tom_go

Masterpiece!

Re: Llewellyn Loco Works #1

Posted: Fri Mar 30, 2018 10:20 pm

by Hydrostatic Dazza

What was that he slipped into his pocket

Re: Llewellyn Loco Works #1

Posted: Sat Mar 31, 2018 10:52 pm

by daan

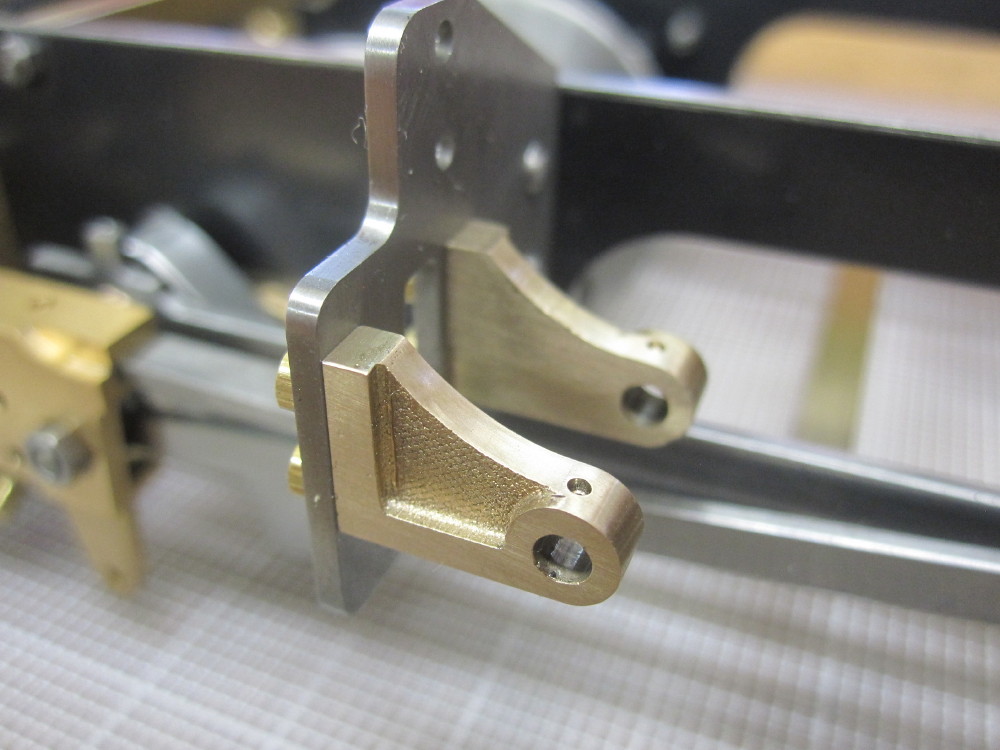

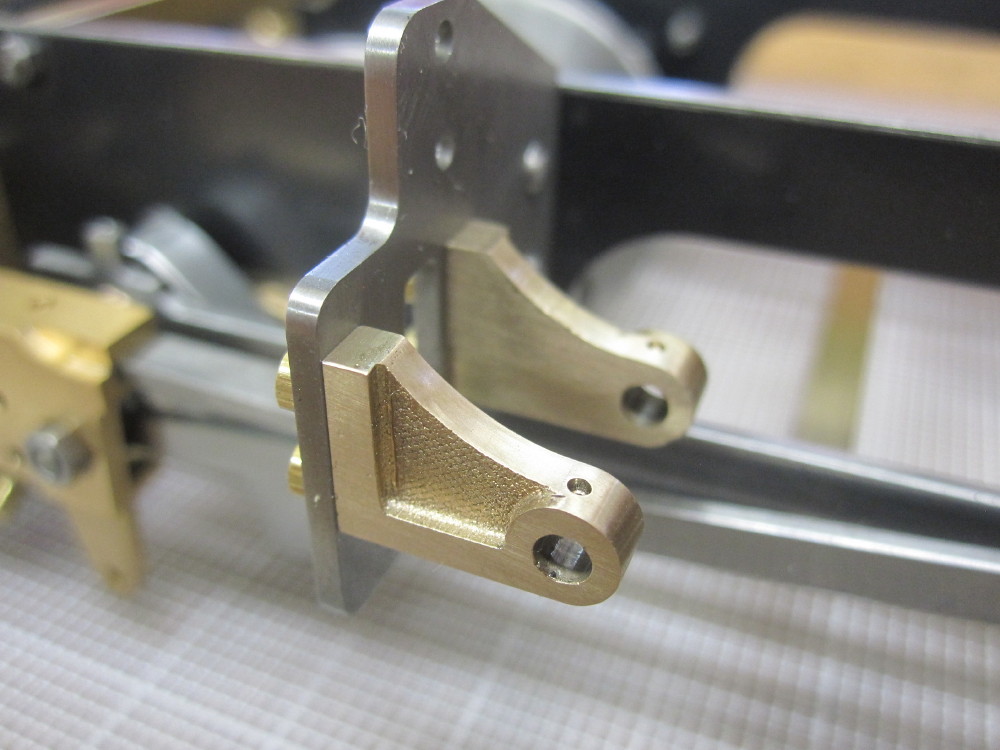

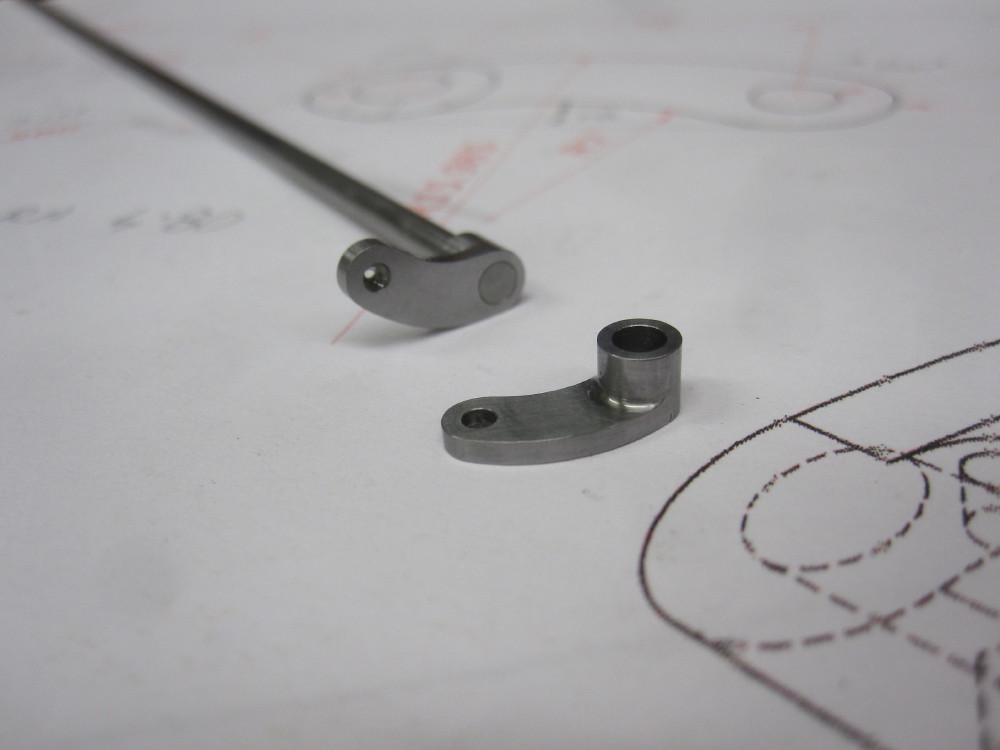

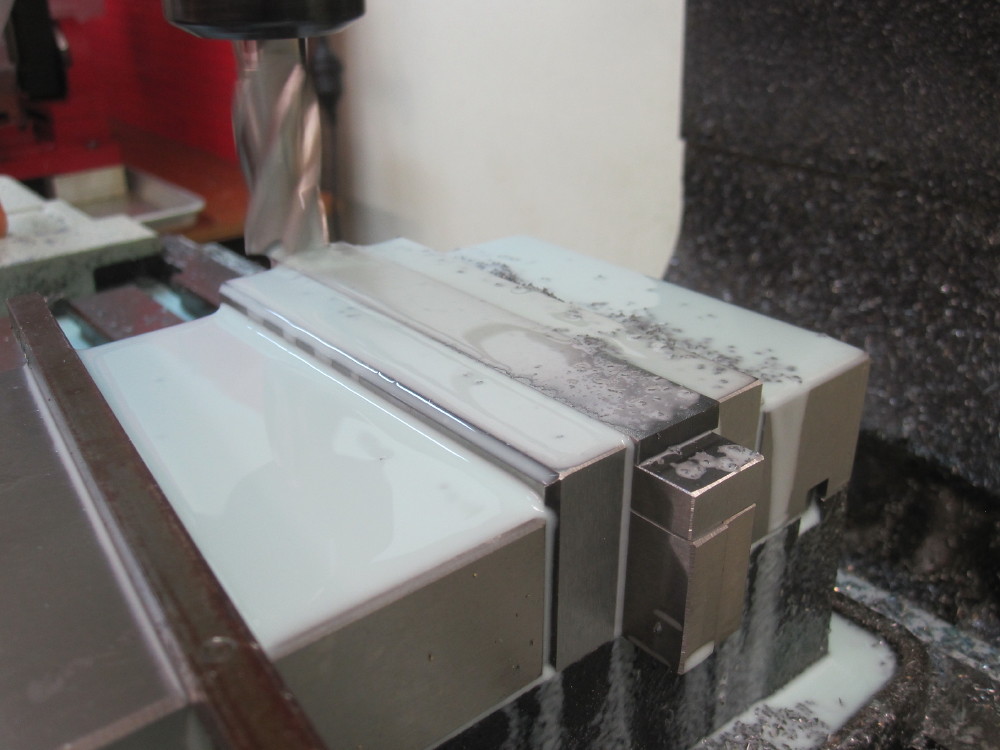

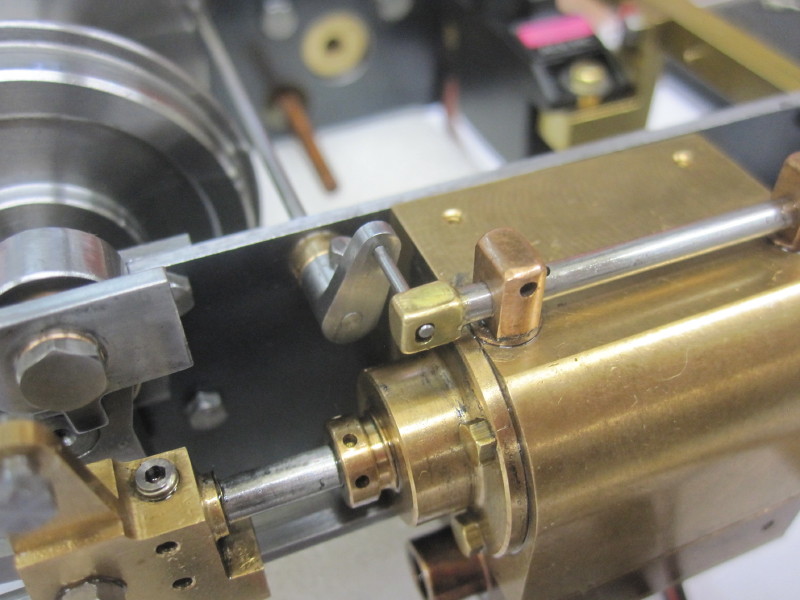

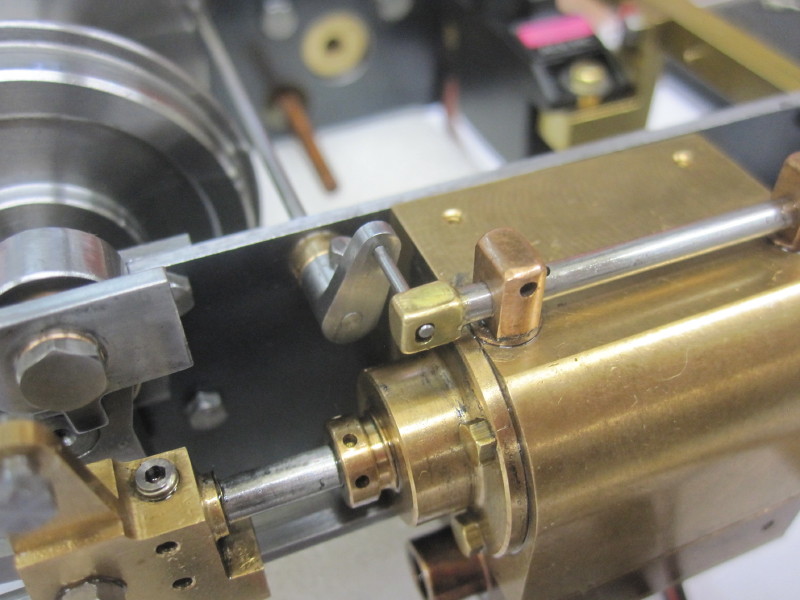

Absolutely great expansion link! Top notch!

Re: Llewellyn Loco Works #1

Posted: Mon Apr 02, 2018 10:16 pm

by Hydrostatic Dazza

daan wrote: ↑Sat Mar 31, 2018 10:52 pm

Absolutely great expansion link! Top notch!

Thank you for the kind compliment, I also thank every one else for their kind compliments. The links drove me to almost a state of despair. Their is evidence of my mistakes, but not showing too loudly. If there is to be a next time, a new design and approach of the these parts will be looked at.

Re: Llewellyn Loco Works #1

Posted: Mon Apr 02, 2018 10:18 pm

by tom_tom_go

Only you know your 'mistakes' although I am sure it's just down to you being critical of yourself (I am the same).

Re: Llewellyn Loco Works #1

Posted: Sun Apr 08, 2018 10:51 pm

by Hydrostatic Dazza

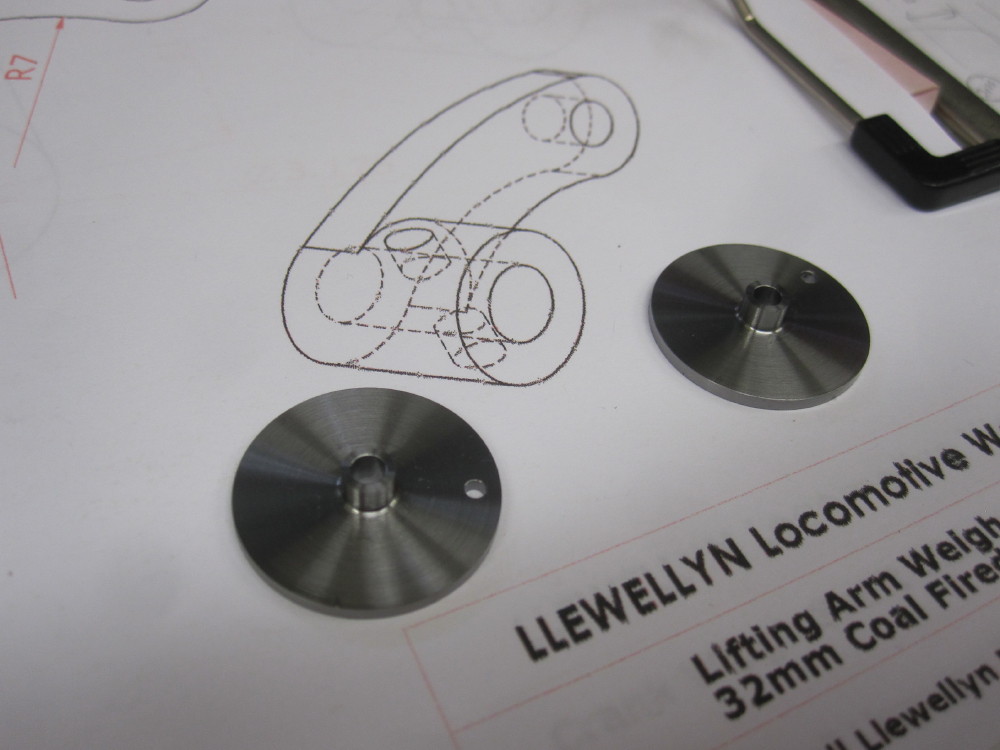

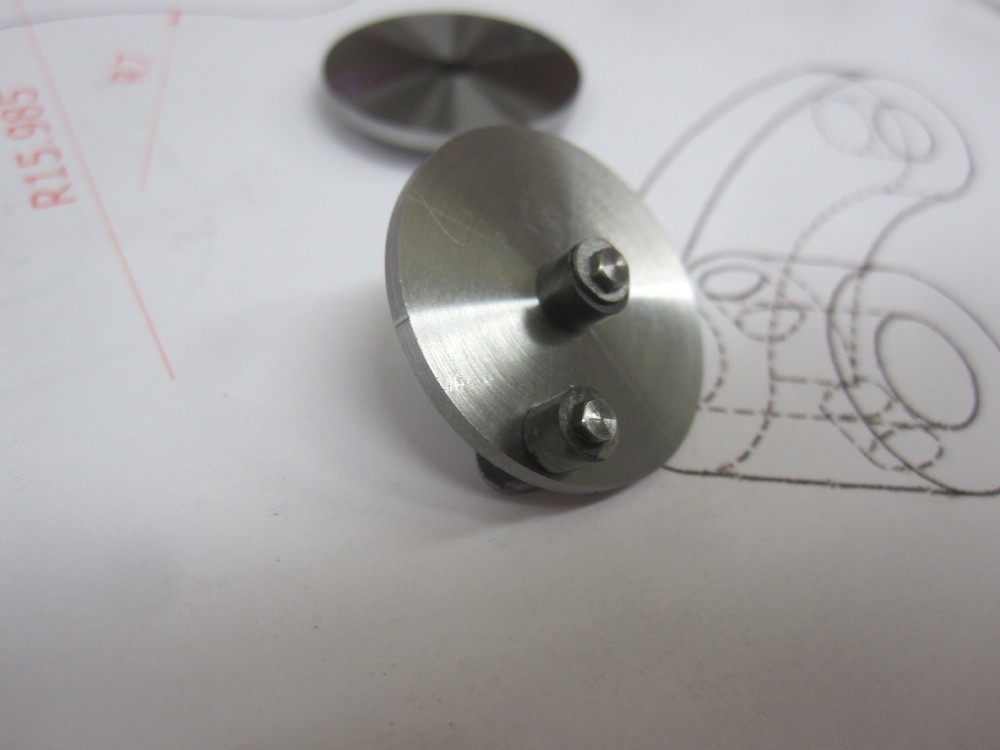

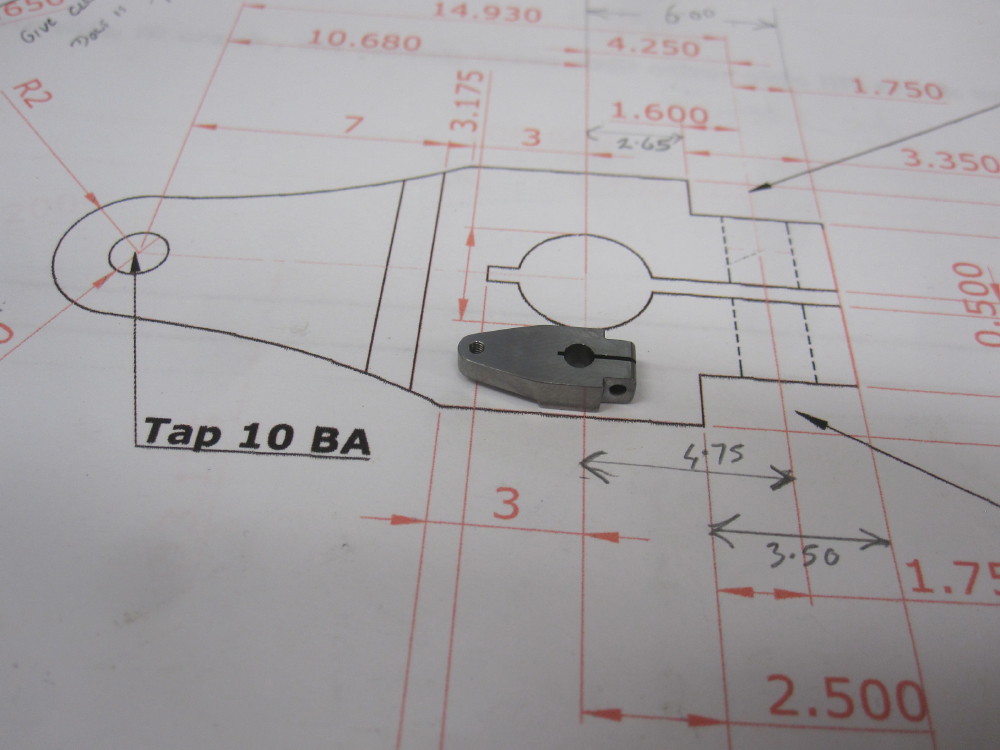

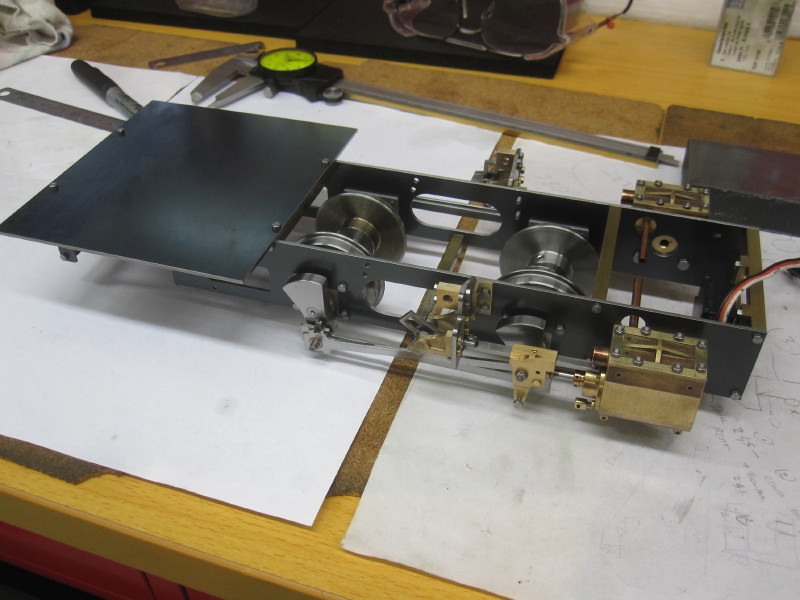

Re: Llewellyn Loco Works #1

Posted: Mon Apr 09, 2018 10:27 pm

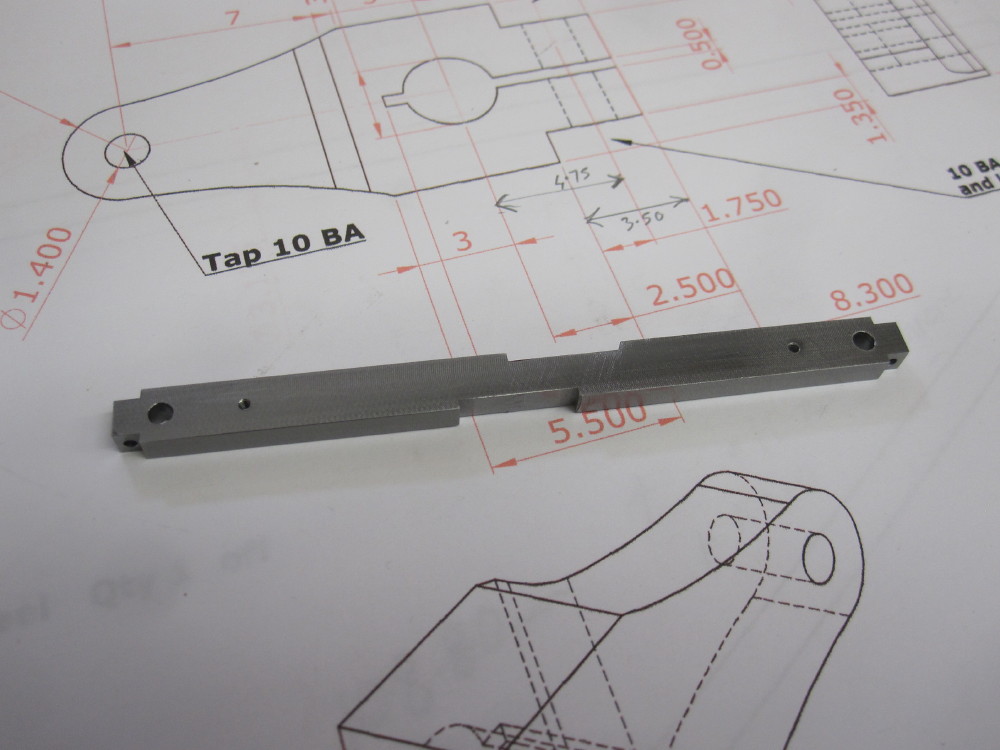

by daan

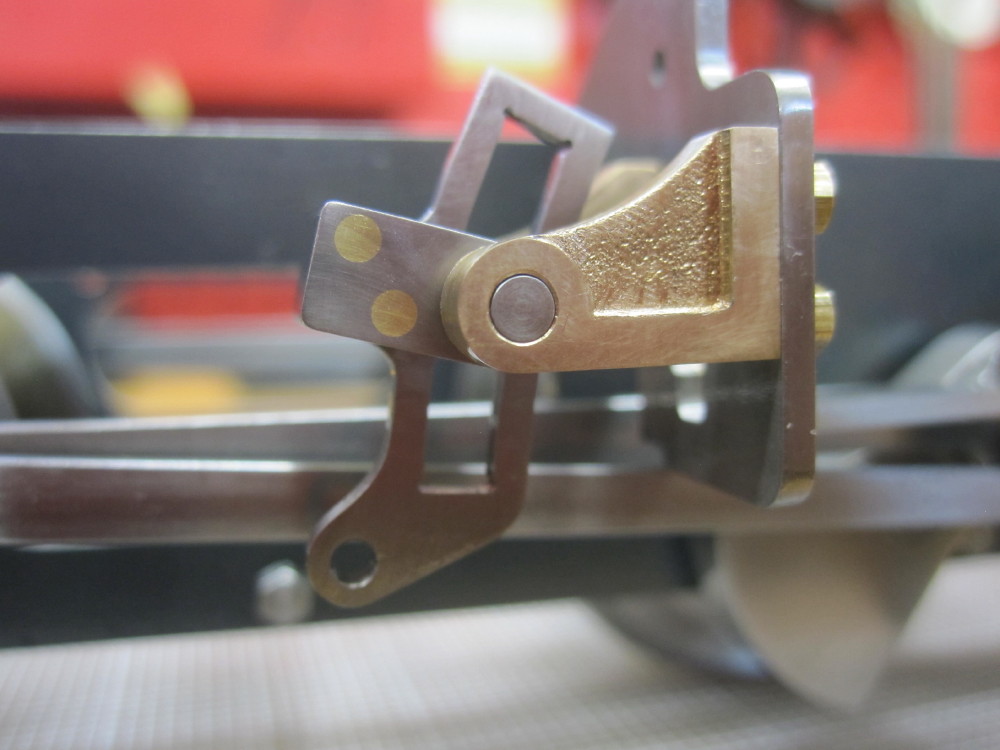

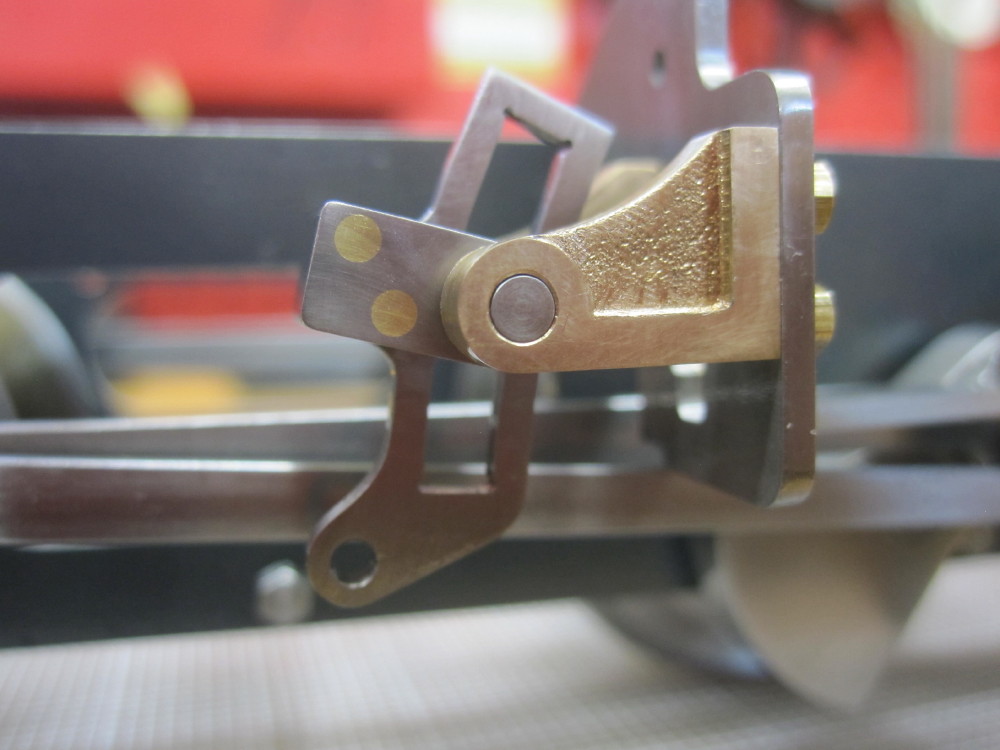

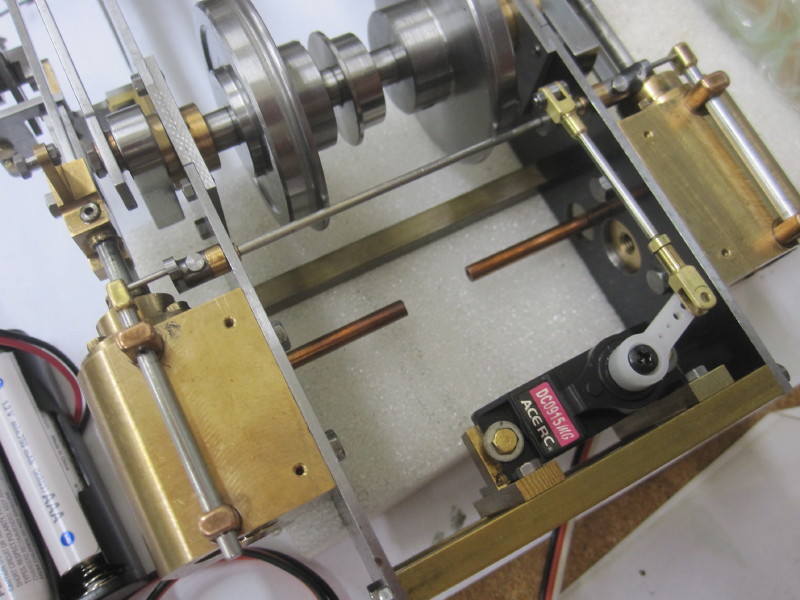

Nice work, these could be one of the most important pieces for a good working steam engine..

Re: Llewellyn Loco Works #1

Posted: Mon Apr 09, 2018 11:17 pm

by Hydrostatic Dazza

daan wrote: ↑Mon Apr 09, 2018 10:27 pm

Nice work, these could be one of the most important pieces for a good working steam engine..

Thanks and agreement, however if I have messed up some where with the redesign I would be very stressed if I had to make new expansion links. That would make me dark!

Re: Llewellyn Loco Works #1

Posted: Mon Apr 09, 2018 11:36 pm

by Hydrostatic Dazza

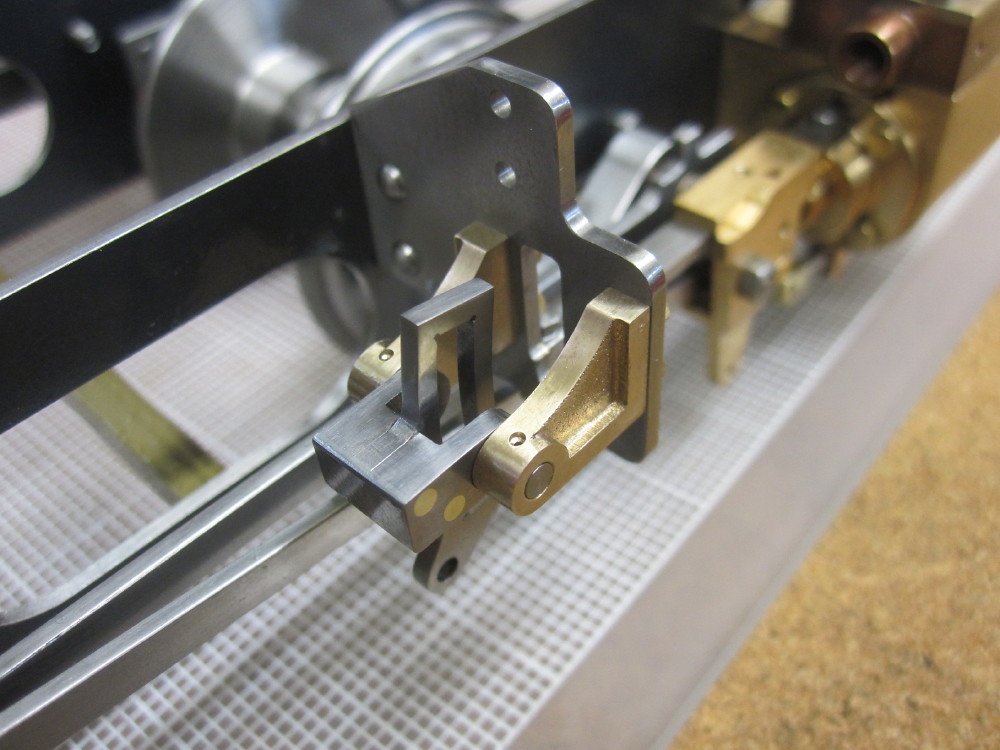

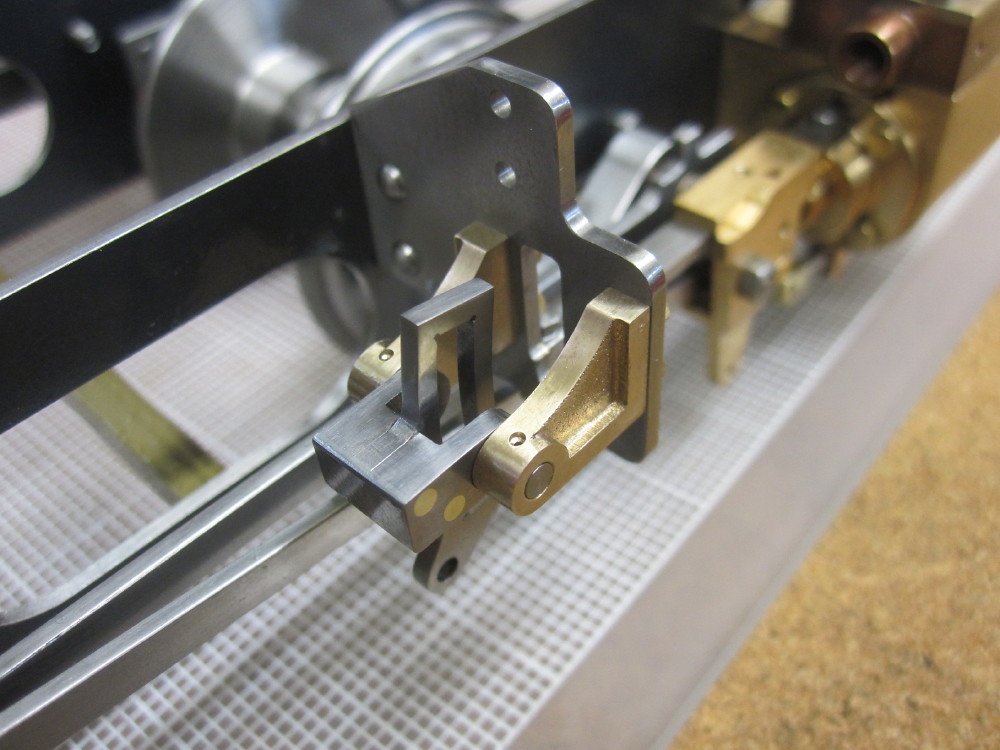

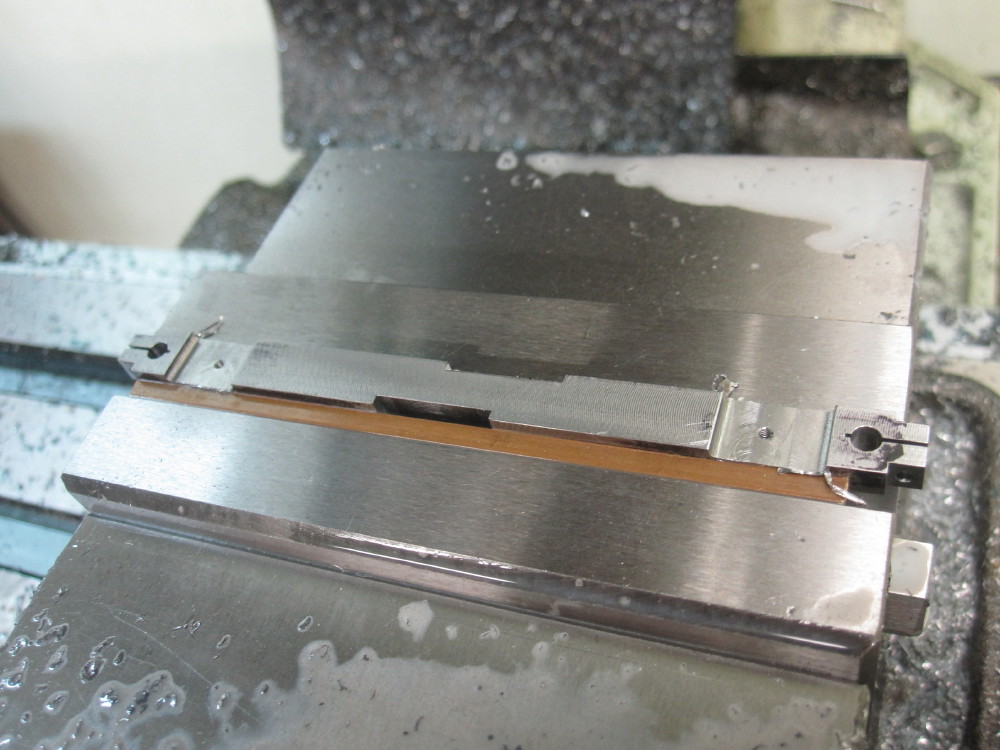

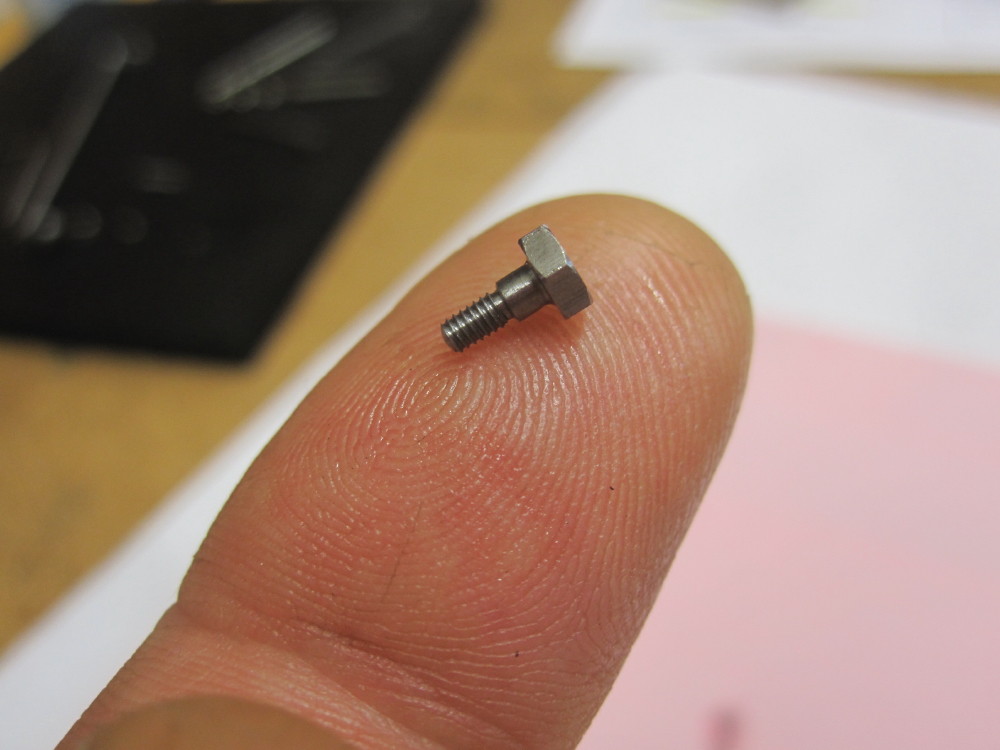

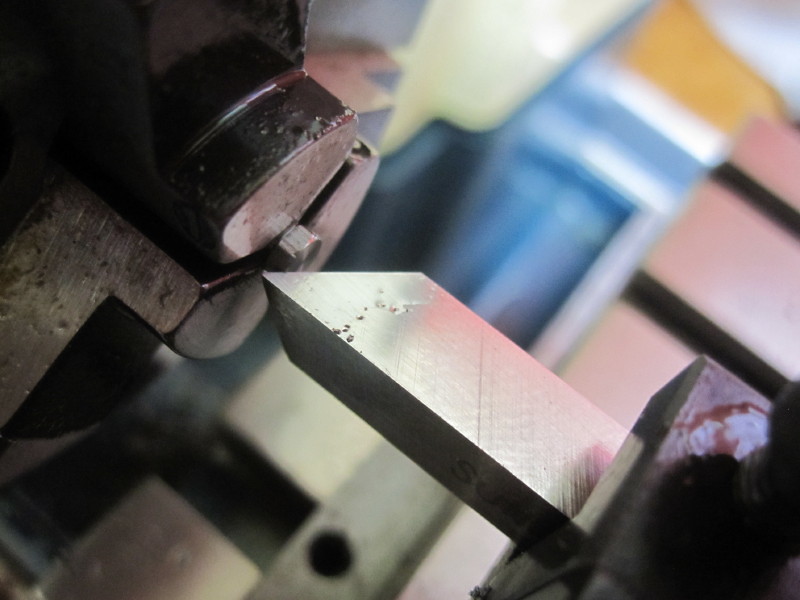

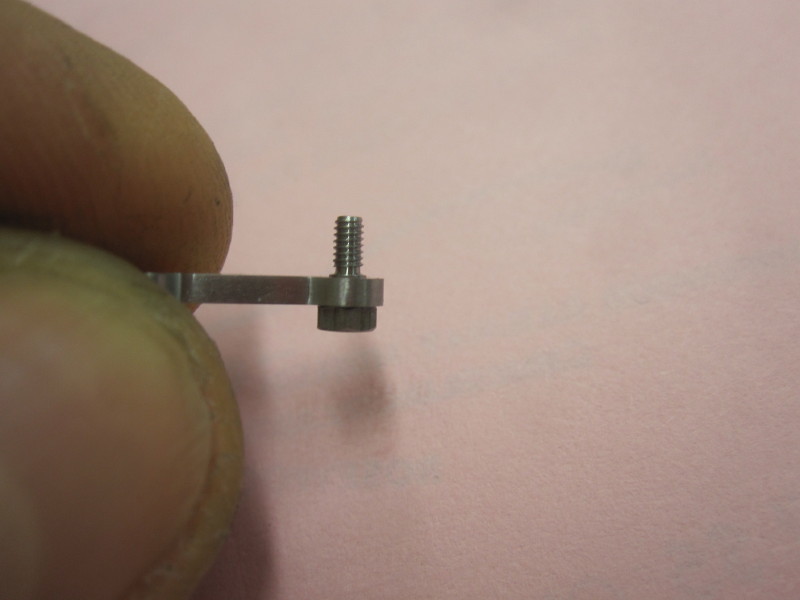

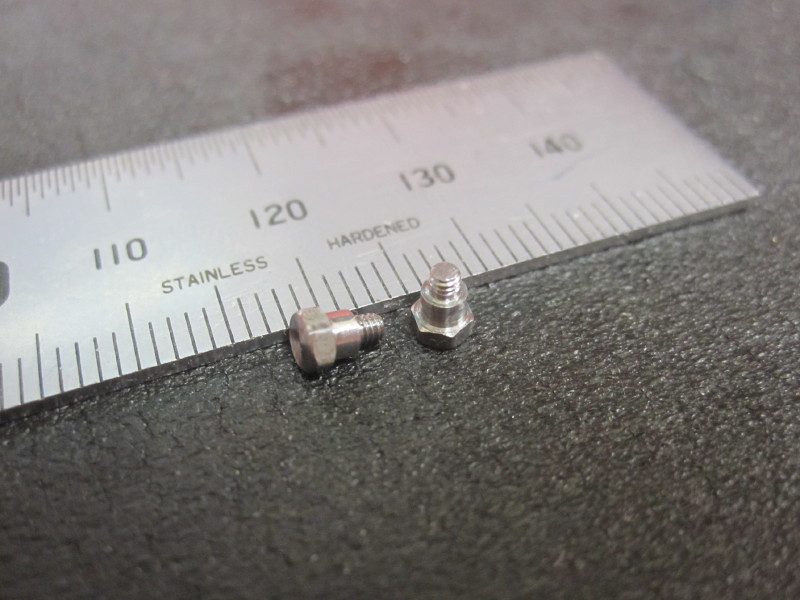

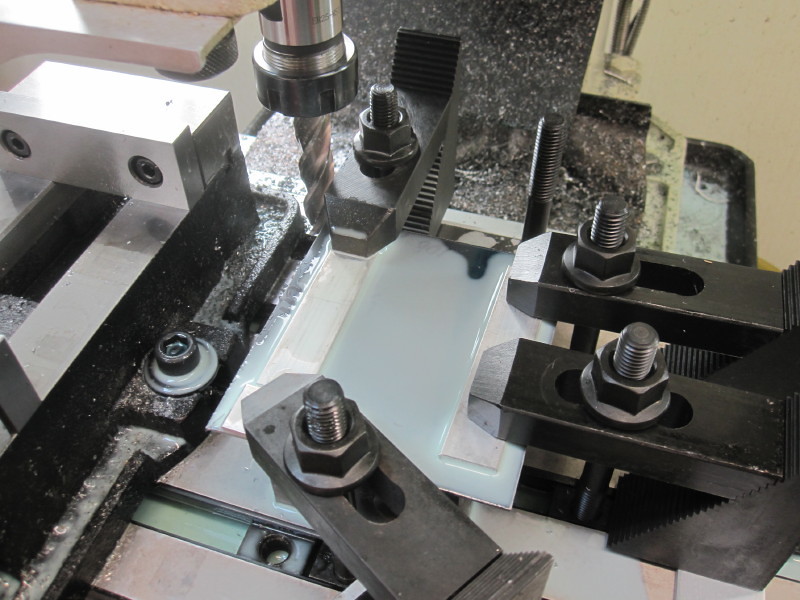

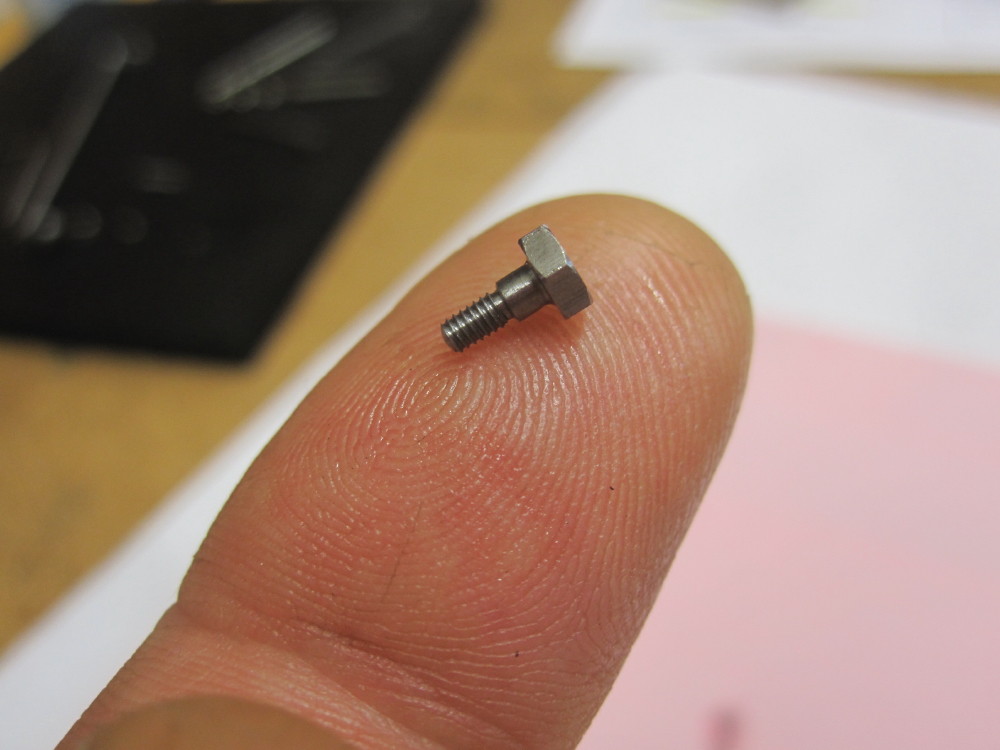

I am making screw pivot pins to connect things, I was having trouble sorting a good reasonably quick but accurate and precise process.

Then suddenly

It comes to me while I made the third pin that was destined for the scrap bin.

Do not make the bolt/pin profile and then cut the thread, instead I turn just the thread diameter and then cut the thread, relieve the last thread to the shoulder. The cut was done with a .50mm parting tool blade that was ground down from a 1/16" blade. Then I turned the 2.02mm diameter, for 1.65mm, chamfer the hex and part off. Then face off the parted surface of the hex head in the Cowells lathe and also trim the threaded section to get the slightly rounded end to the thread.

I know this sequence might be bleeding well obvious to most, but for dim old me , it was YAY!

Re: Llewellyn Loco Works #1

Posted: Tue Apr 10, 2018 7:56 am

by tom_tom_go

Yeah, that's what I would of done (he says jokingly).

Re: Llewellyn Loco Works #1

Posted: Tue Apr 10, 2018 9:43 pm

by Hydrostatic Dazza

tom_tom_go wrote: ↑Tue Apr 10, 2018 7:56 am

Yeah, that's what I would of done (he says jokingly).

Re: Llewellyn Loco Works #1

Posted: Tue Apr 10, 2018 10:07 pm

by Hydrostatic Dazza

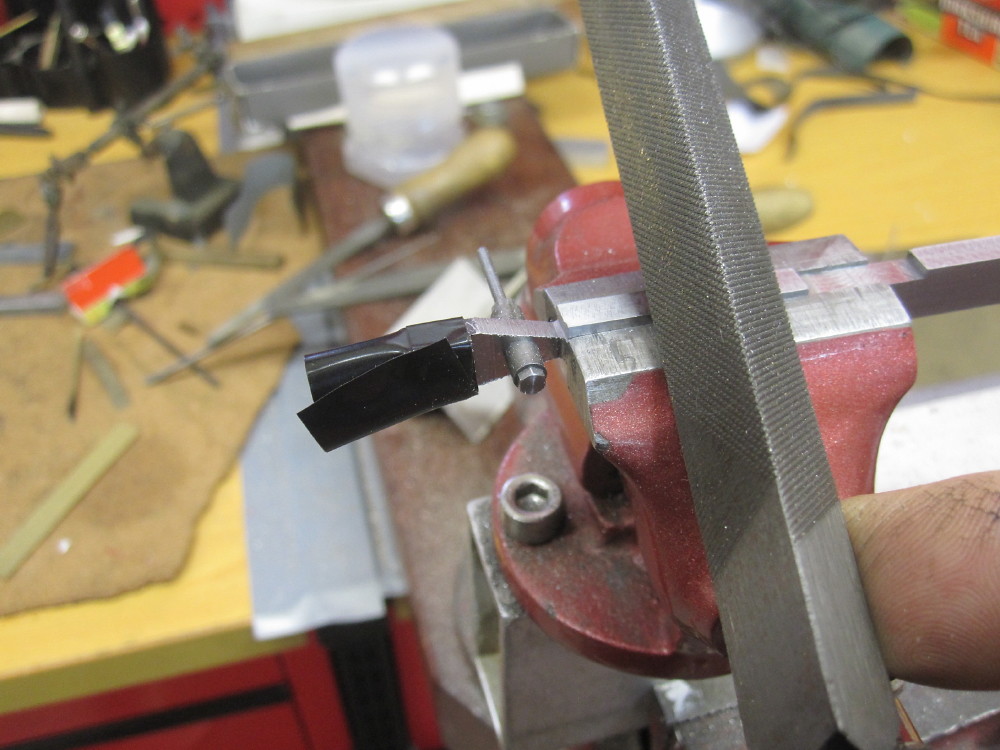

If I drop a motion pin on the 12" to the foot scale I crack a toe open, leaping about with curses spewing out, or at least a good test for the steel caps.

If I drop one of these and I am on my hands and knees, squinting.

These motion pin/bolts take an inordinate amount of time to make.

Re: Llewellyn Loco Works #1

Posted: Sun Apr 15, 2018 11:41 pm

by Peter Butler

I like tidy but you work in an operating theatre!

Wonderful stuff though and rapid too.

Re: Llewellyn Loco Works #1

Posted: Mon Apr 16, 2018 9:04 am

by pandsrowe

Blimey, that floor is clean enough to eat your dinner off. Seriously though I also like to work in a (relatively) clean environment but I'm always torn between keeping it clean and tidy and the time it takes to have a tidy up.

Re: Llewellyn Loco Works #1

Posted: Mon Apr 16, 2018 9:09 am

by daan

Absolutely brilliant! The workshop you have, as well as your locomotive..! I'll show your workshop at my work as an example of how a professional workspace should look like.

The best thing about it is the floor however. It can be cleaned with water and soap, you see every tiny bit you drop and it is light, so you see what you're doing.

The only important thing I don't see is a good stereo.. I've moved my old Pioneer surround system to the shed, which can be linked to my phone for any kind of music I feel like, no matter what volume.. I guess that is the best thing in my workshop.

Re: Llewellyn Loco Works #1

Posted: Mon Apr 16, 2018 10:01 pm

by Hydrostatic Dazza

daan wrote: ↑Mon Apr 16, 2018 9:09 am

Absolutely brilliant! The workshop you have, as well as your locomotive..! I'll show your workshop at my work as an example of how a professional workspace should look like.

The best thing about it is the floor however. It can be cleaned with water and soap, you see every tiny bit you drop and it is light, so you see what you're doing.

The only important thing I don't see is a good stereo.. I've moved my old Pioneer surround system to the shed, which can be linked to my phone for any kind of music I feel like, no matter what volume.. I guess that is the best thing in my workshop.

Epoxy floor is a beautiful thing, cleans up and washes off and dries fast. I need to do the bike making area as well, but the disruption to the cash flow will be huge.

You are correct about the stereo, MAM bought me one and I have to put some shelves up and set it up. I have a wall TV antenna socket and power supply for a TV so I can watch the test matches but I do not think I will install a TV. It was a silly idea. I do not use a mobile phone let alone a smart phone. I am still a CD man. I listen to Radio National all day on the digital radio but a lot of the time I am in the Red Room I listen to the ABC's Jazz channel . I am a Nick Cave fan and Bowie and ....................all sorts. Driving is Nick Cave. Unless cricket is on the radio, then it must be cricket. Cleaning does take time however it makes me feel relaxed and confident in my hobby.

Re: Llewellyn Loco Works #1

Posted: Wed Apr 18, 2018 3:26 am

by Hydrostatic Dazza

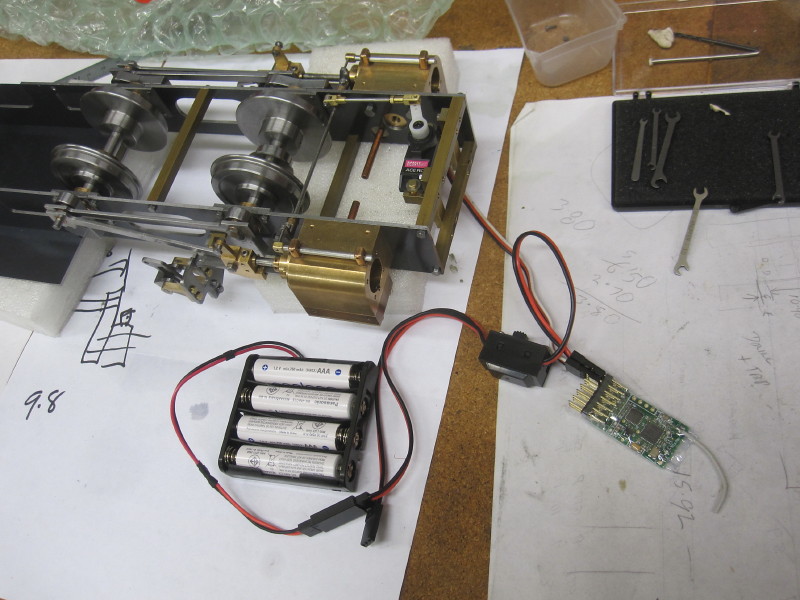

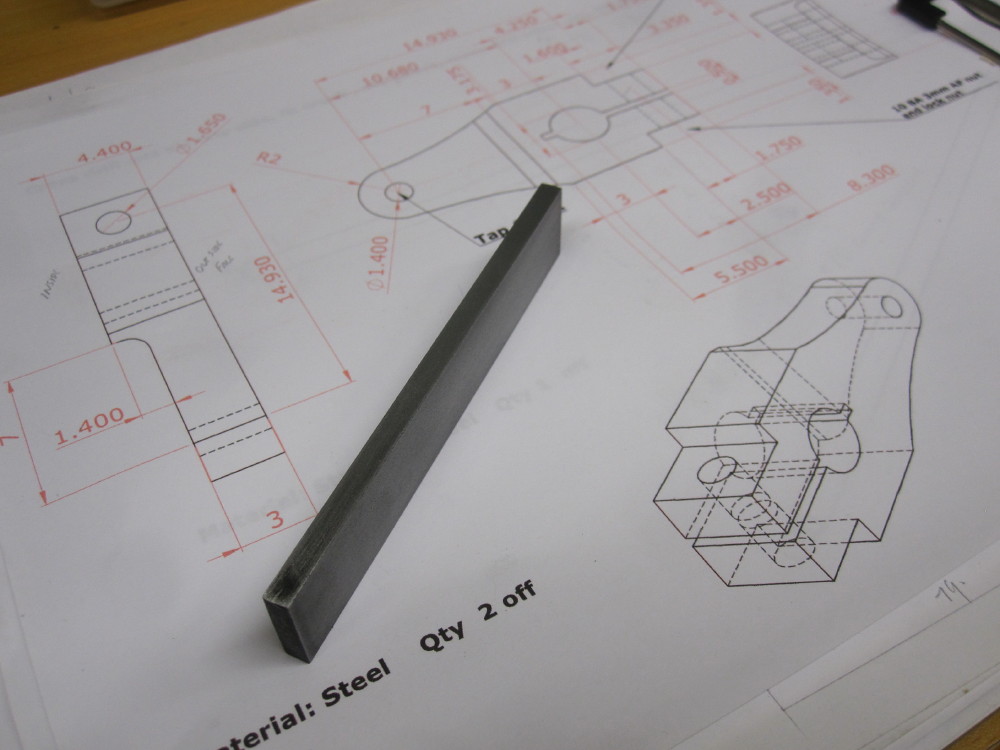

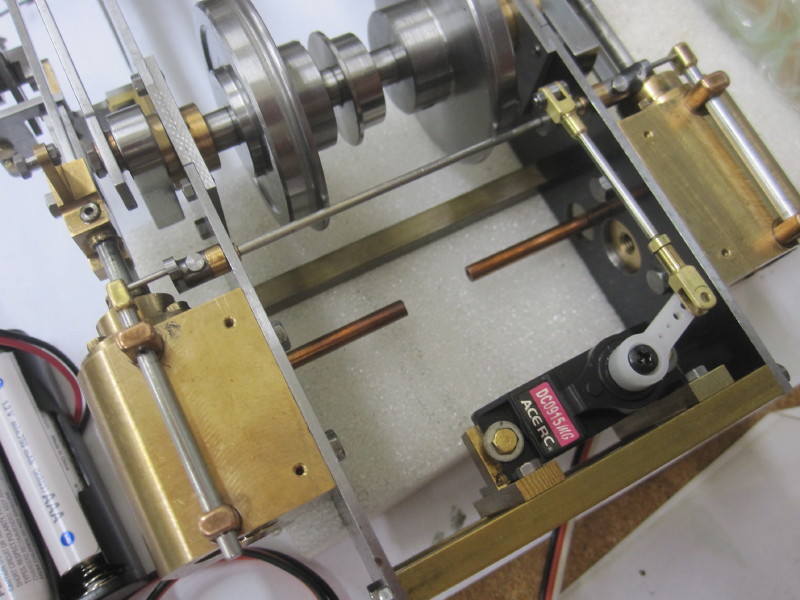

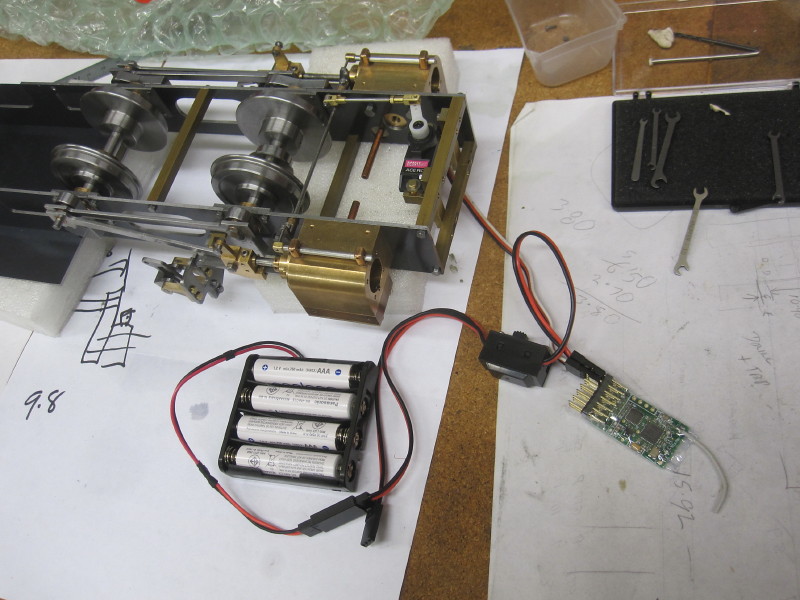

Last night after 11 hours in the bike workshop (preshow stress) after dinner I spent some time finishing off installing the cranks for the drains.

Then I was trying to get the Servo to twitch the right amount, but not mastered, it was getting late and I was tired so off to the feathers I went.

Then I was trying to get the Servo to twitch the right amount, but not mastered, it was getting late and I was tired so off to the feathers I went.