Had a bit of a catastrophe on Sunday at the running day.

Somehow, the coaches behind Osprey managed to derail, thus digging the bogies into the track, the tender pin had come apart from the loco somehow, so as I opened the throttle ( not realising the derailment!), the loco split from the tender, giving me no control, hurtled round a corner and fell 3ft off the side onto gravel

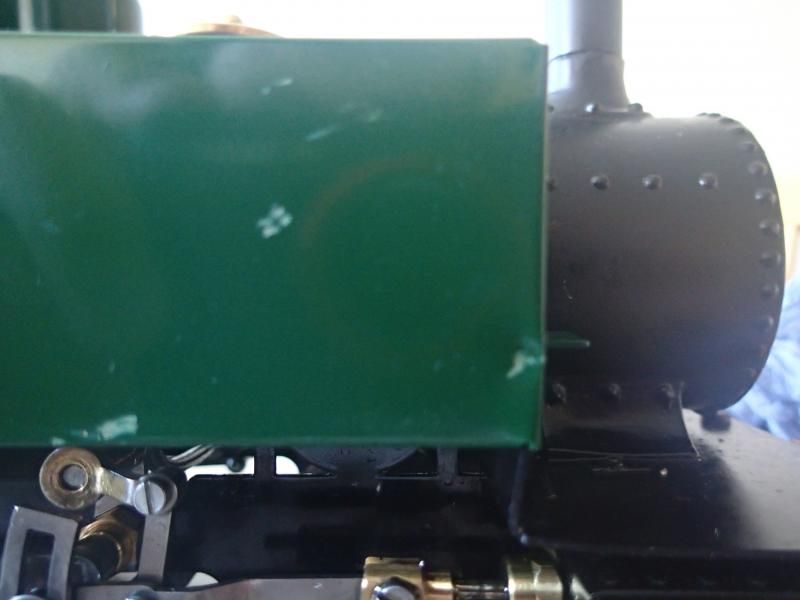

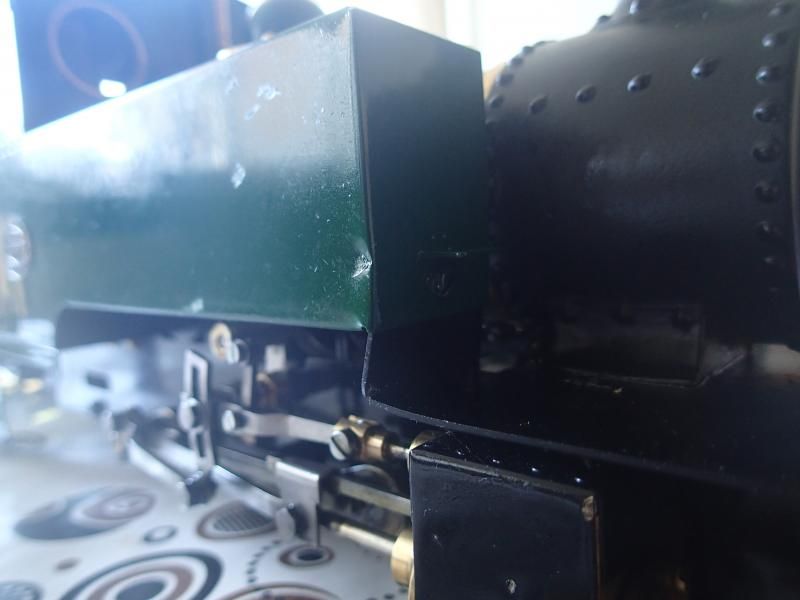

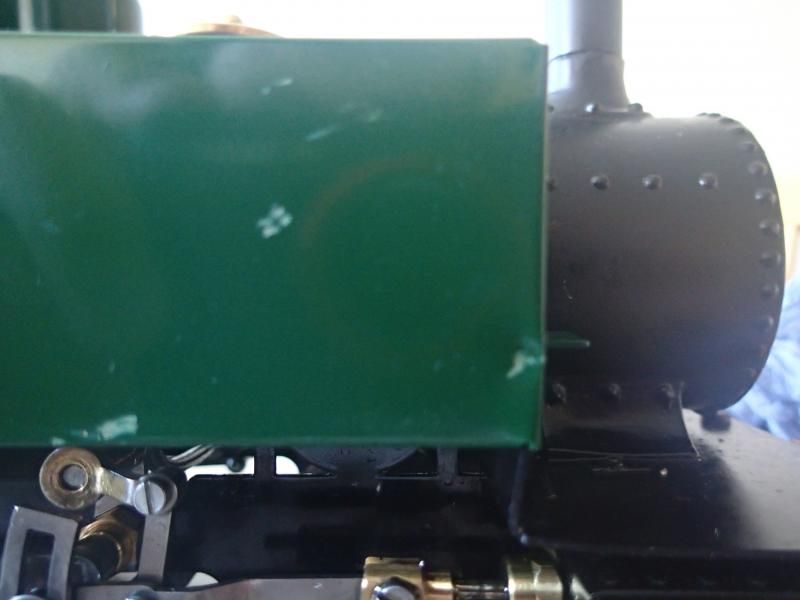

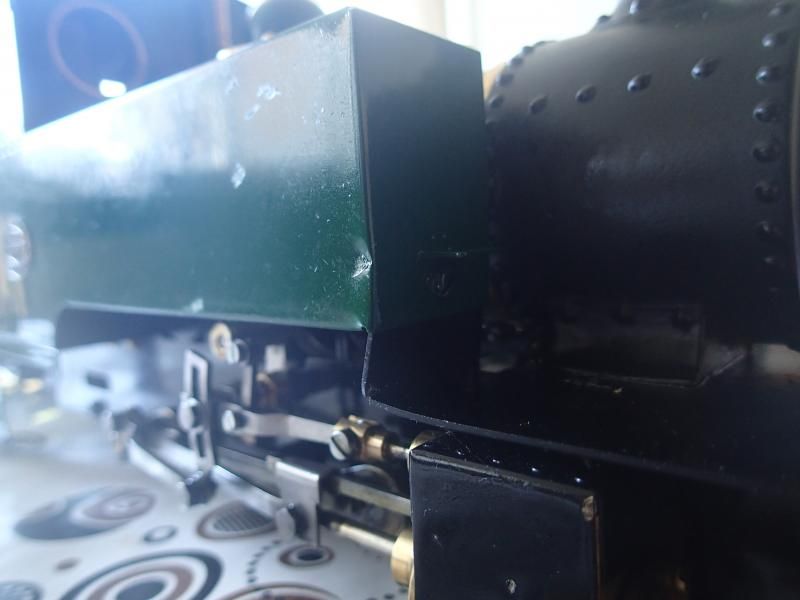

I think the damage is mainly cosmetic, the chassis doesn't seem to be twisted. All the cosmetic oilers, a nameplate and a numberplate have come off, luckily these were found. There are a few chips and scratches in the side tanks, which appear to have taken the brunt of the damage...

And one of the other side, which has come out best, I think the loco flipped before it hit deck!

So. I'm gonna be busy getting this repaired

However, one thing I am concerned about, if the tender had not come undone from the engine, none of this would have happened because I would not have lost radio control of the loco. I need to find some way of holding the pin from the tender from coming up and out of the locos drawbar. On my 5 inch gauge stuff, I use an R-Clip, but the pin on that is massive, not sure how I'm going to sort this out...

Cheers!

Steven.