Page 1 of 9

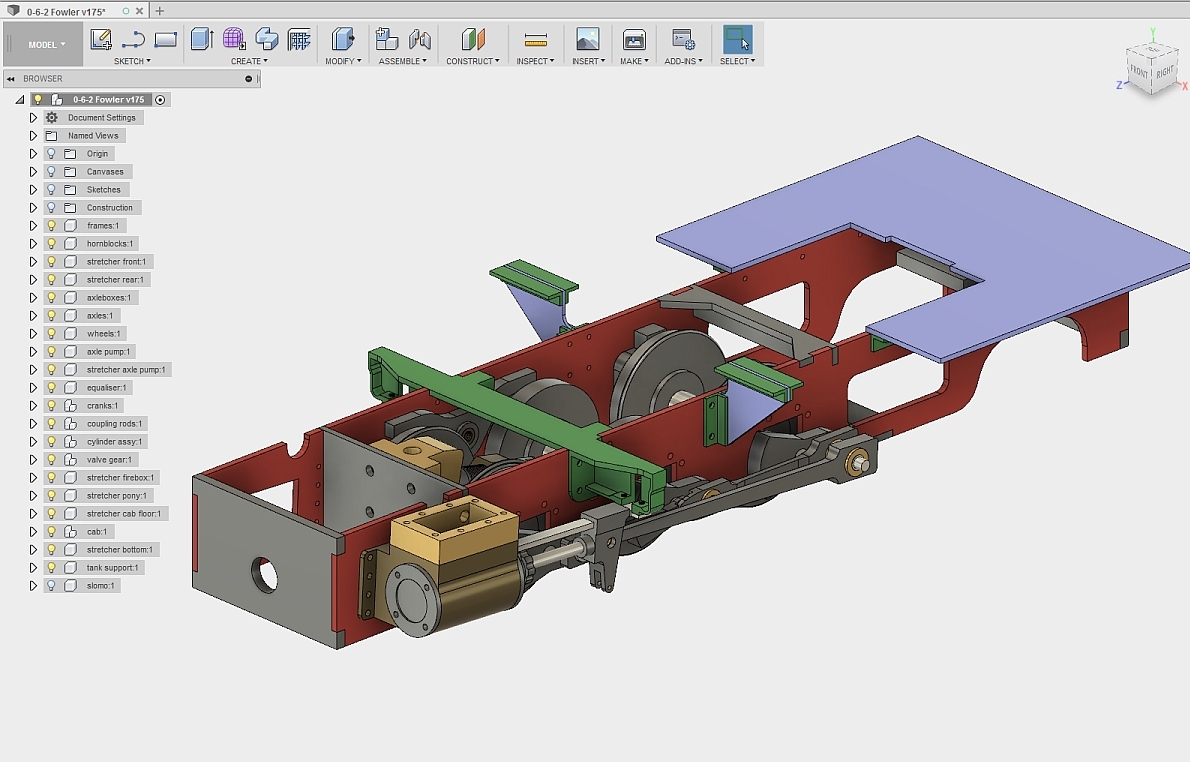

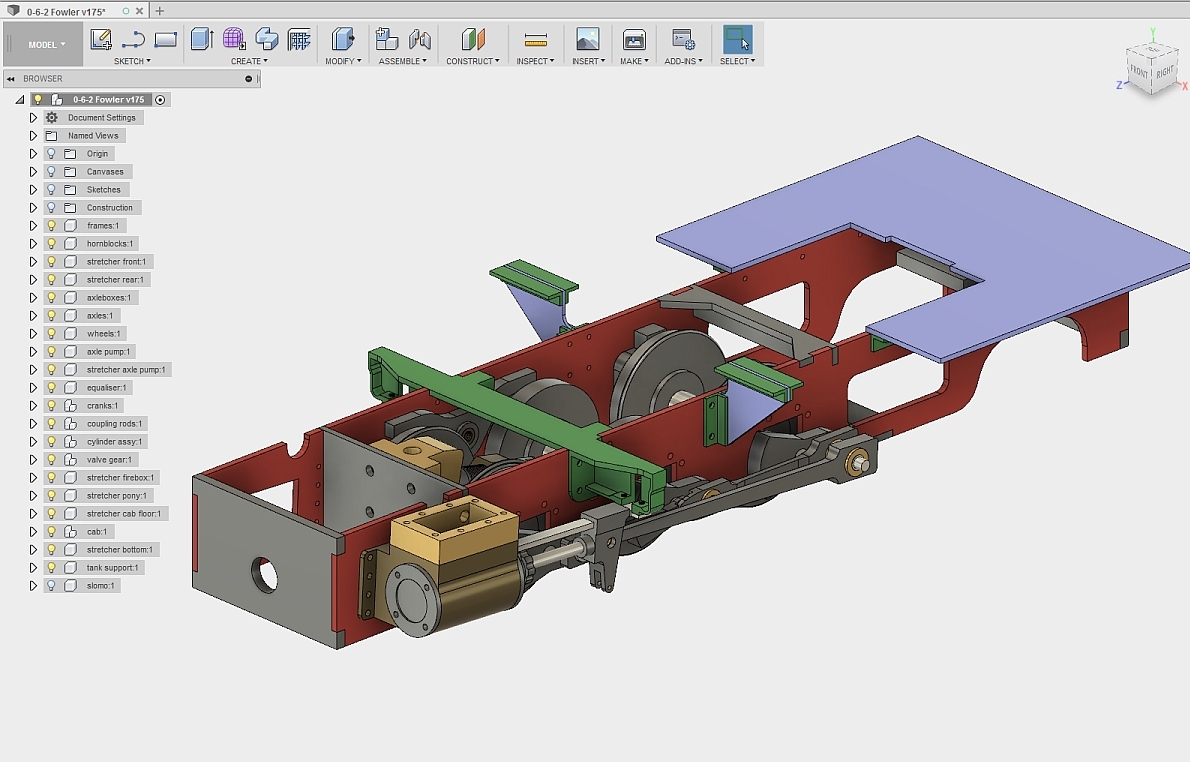

bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 2:42 pm

by bambuko

It's really freelance, Fowler inspired

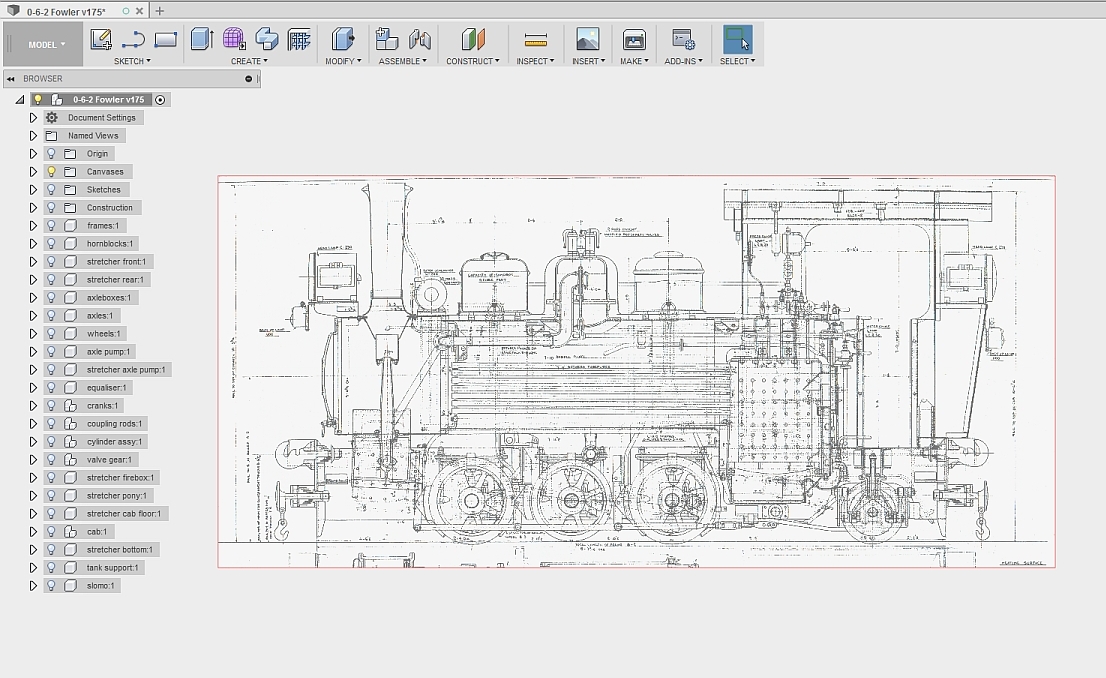

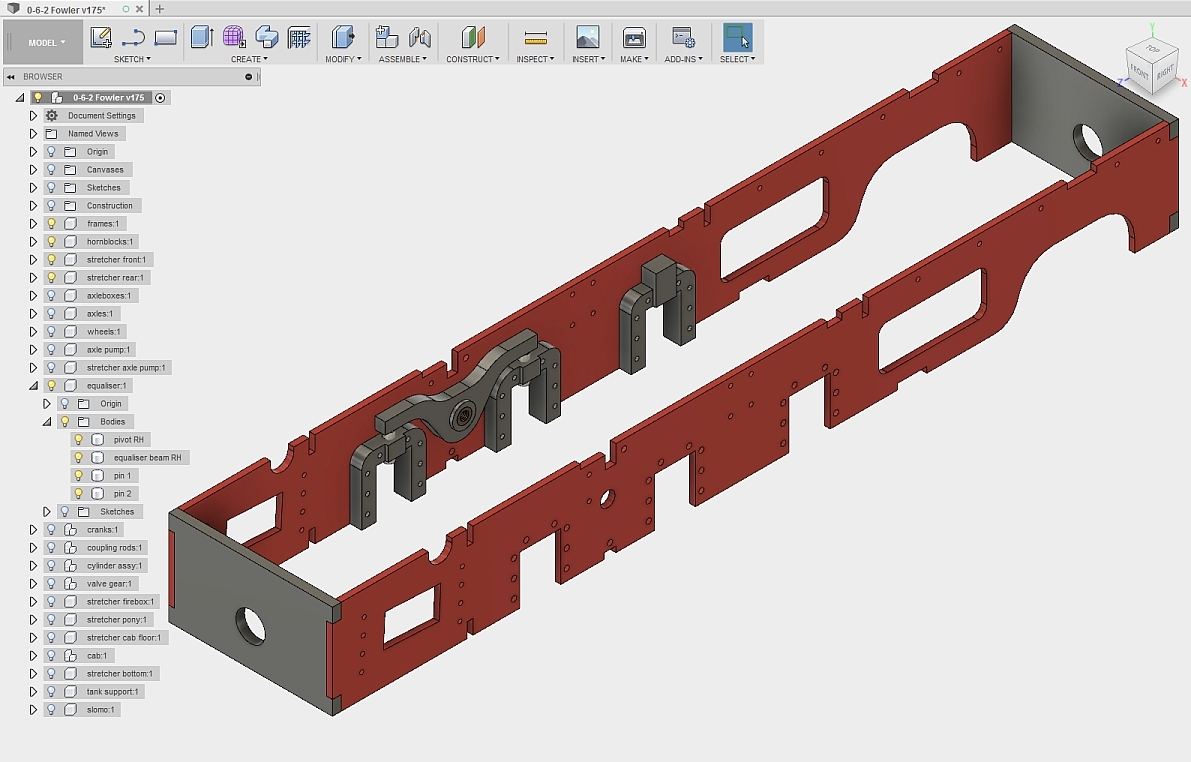

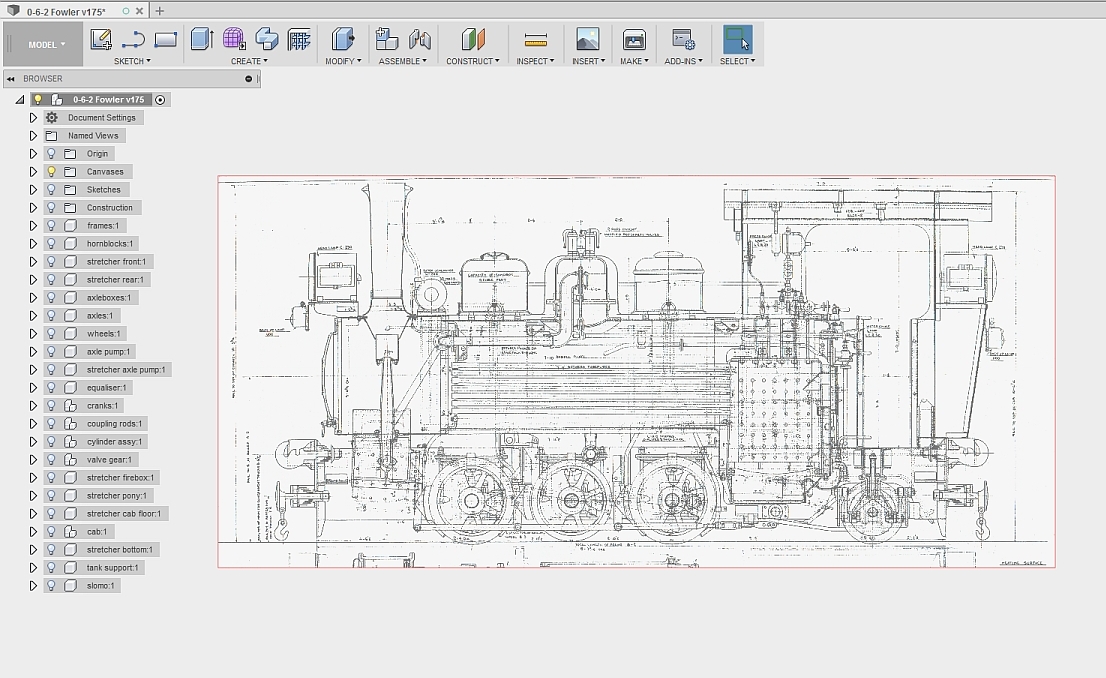

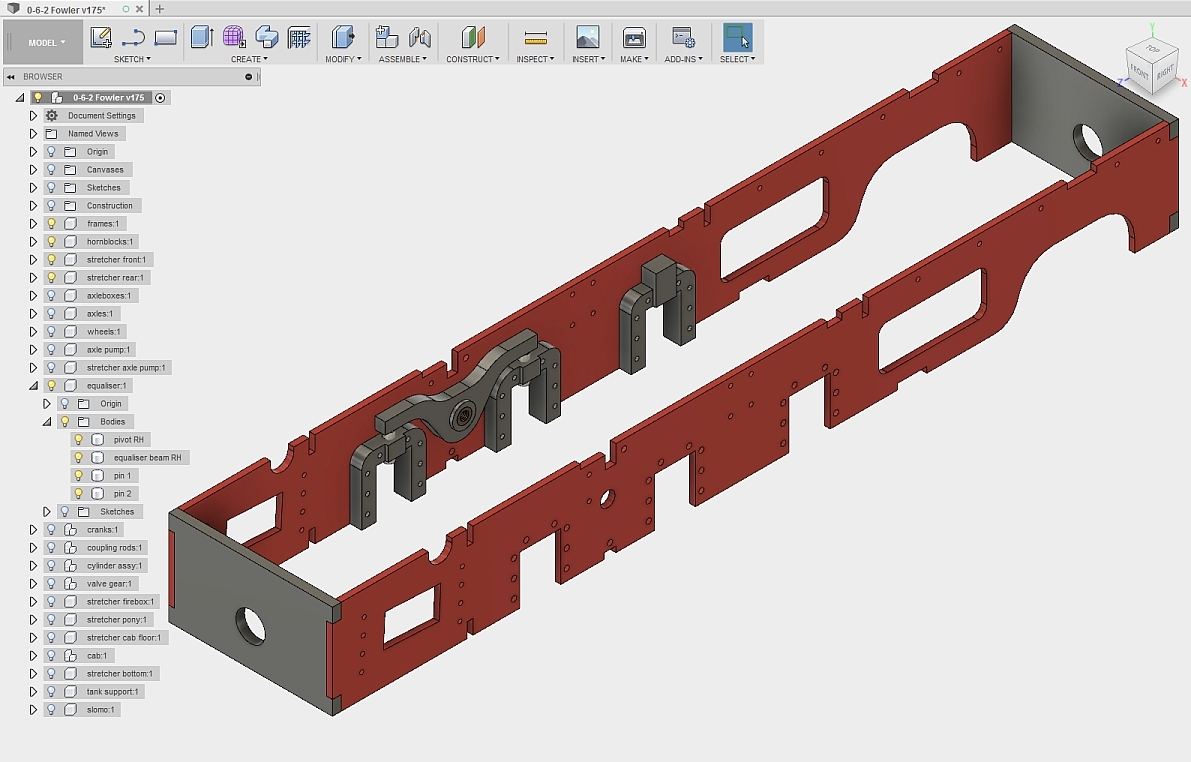

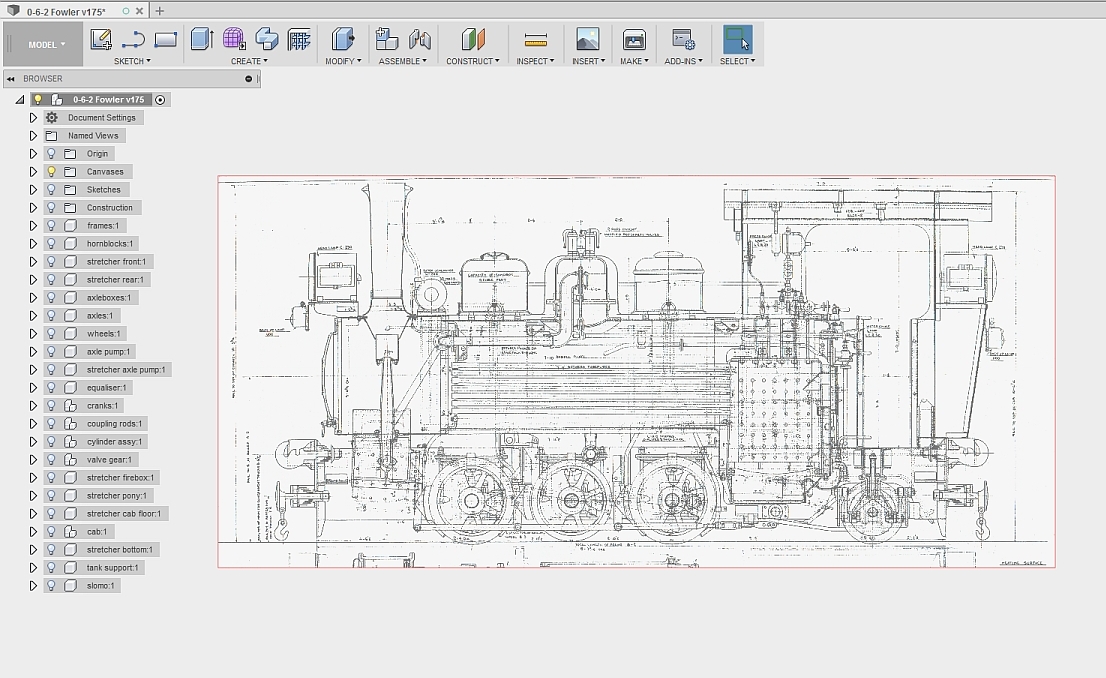

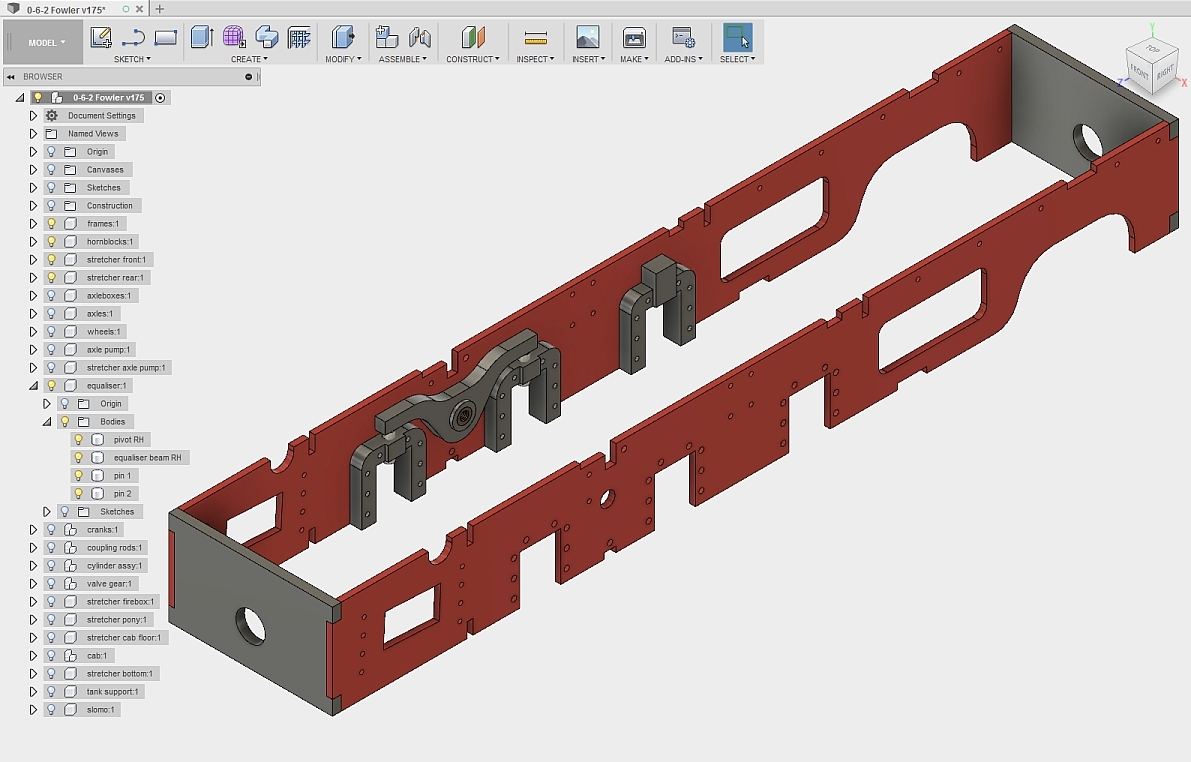

Using Fusion 360 for CAD modelling.

Imported manufacturer's drawing on page 136 in Brian Wilson's book into CAD:

Two front (coupled) axles are to be equalised and rear (driven) axle is to be sprung (giving in effect four point suspension):

We shall see... how it comes out

The idea is that with three axles without suspension of some kind, only two axles at best give you some traction. It's probably un-necessary complication (as proven by countless 16mm locos) but it is my railway, so whatever rocks my boat goes

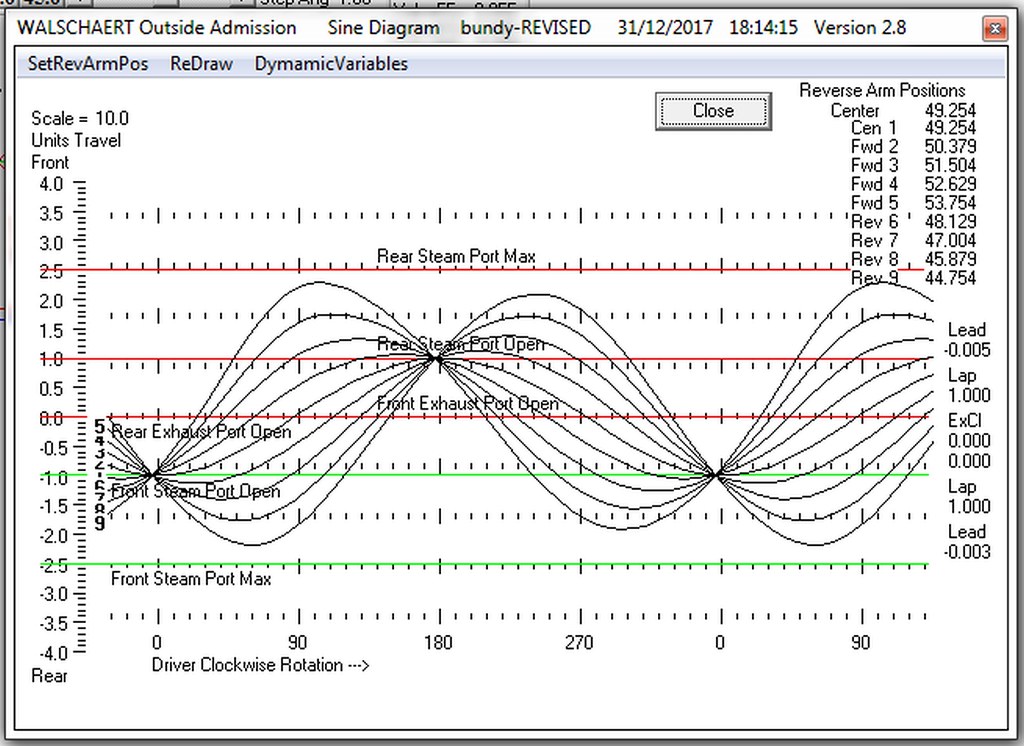

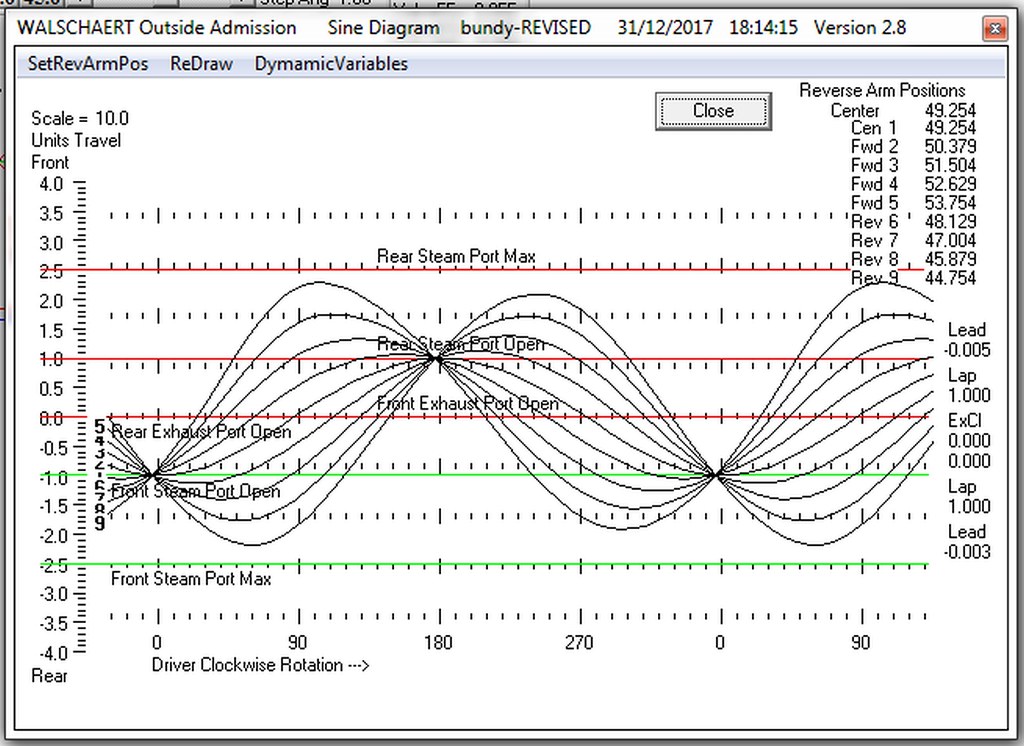

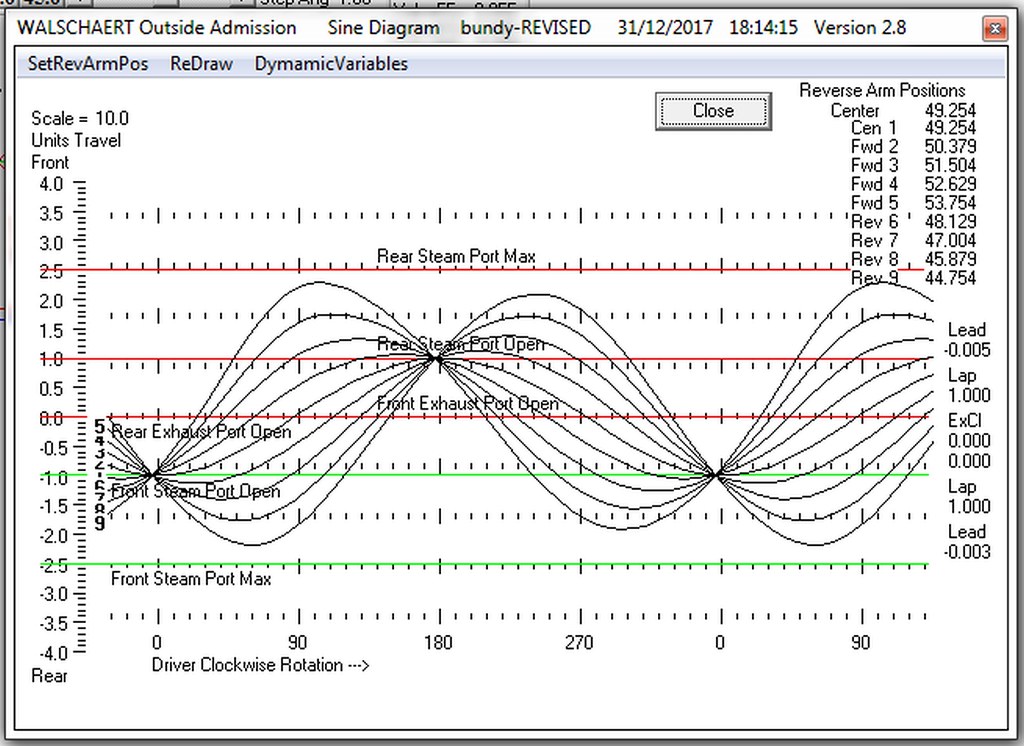

I did some analysis of valve gear and changed it slightly, to get valve events slightly better (I know it is presumptious of me

)

Using W. B. Hall's "An approximate, but logical, method of designing valve gear", followed by D. L. Ashton's "Design Procedures for Valve Gear" I have come up with a design for Walschaerts gear:

TBC

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 2:51 pm

by bambuko

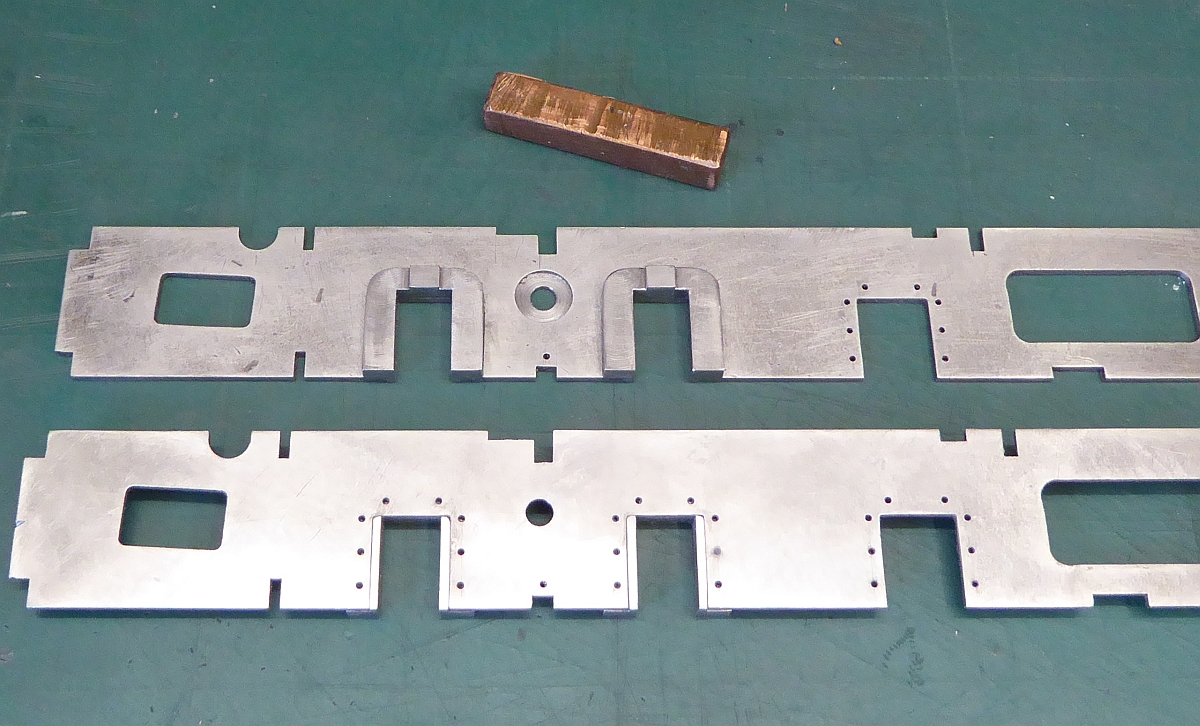

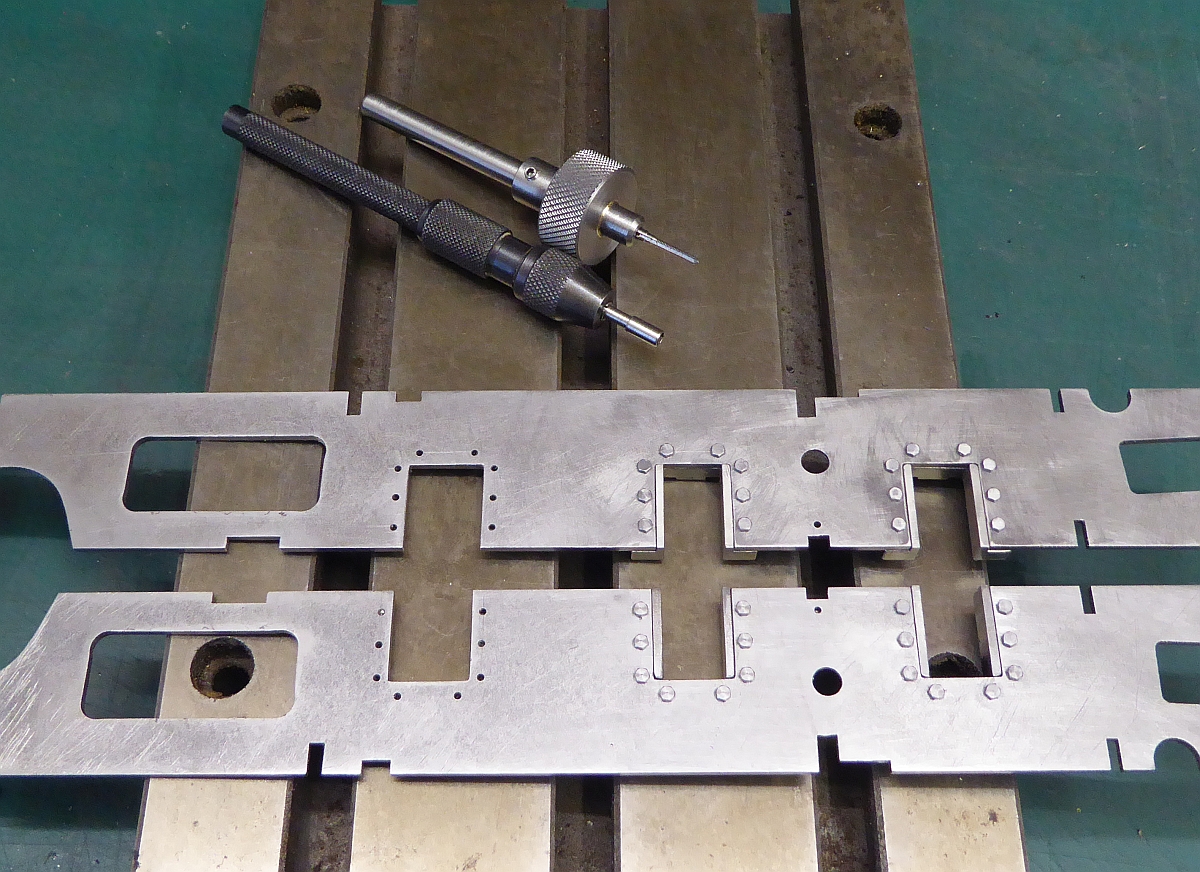

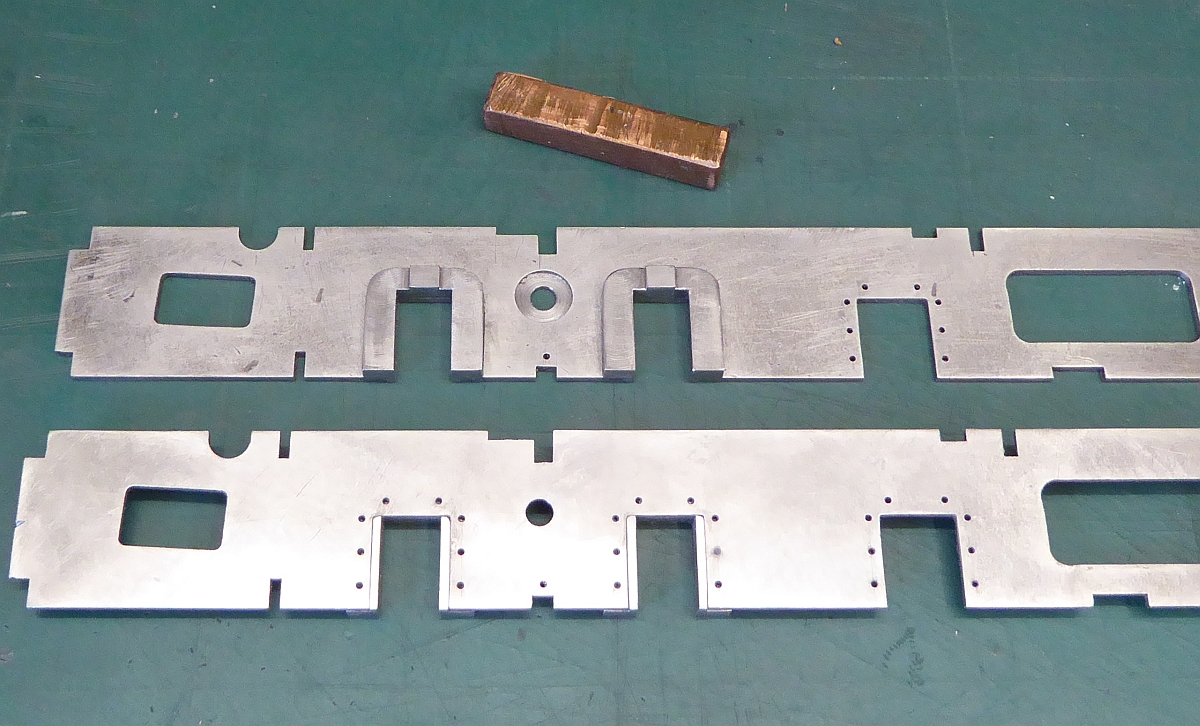

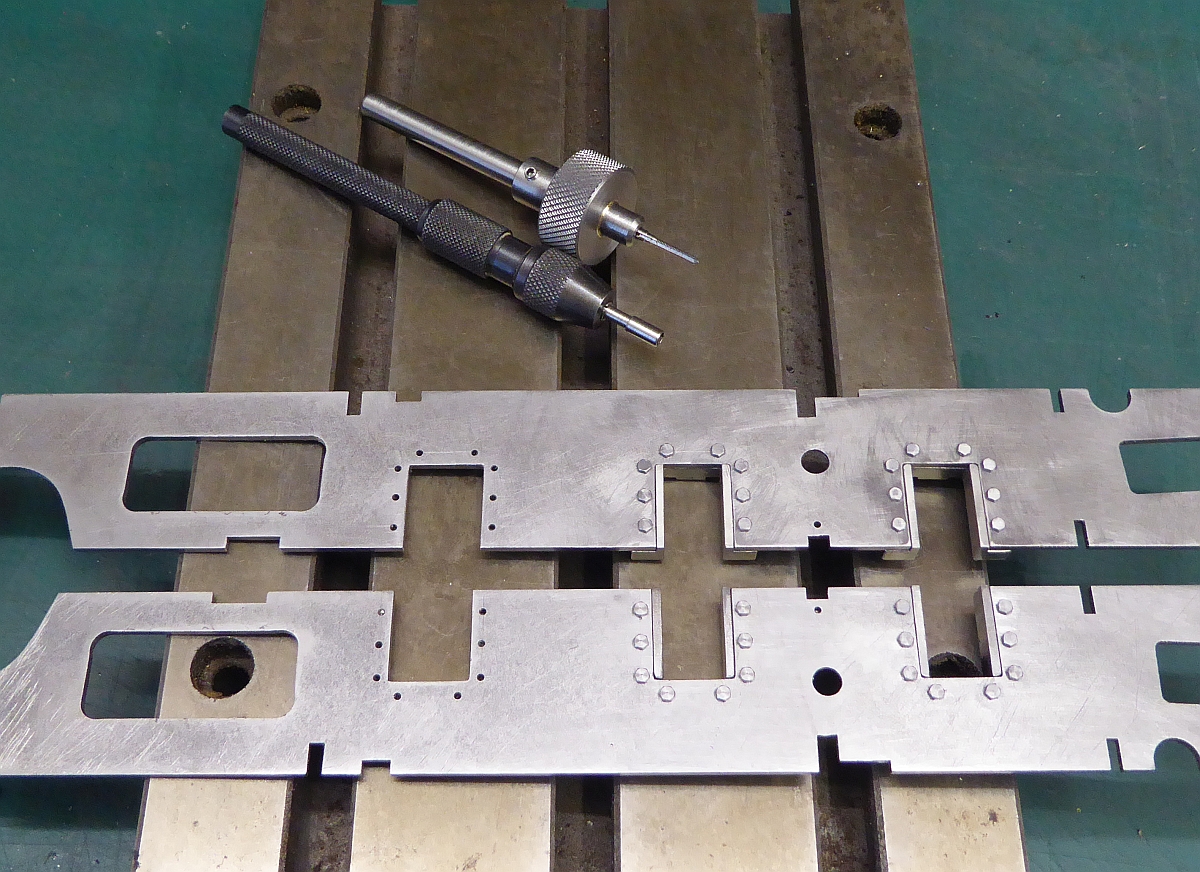

That's how far the CAD design got, before I have decided to start cutting metal:

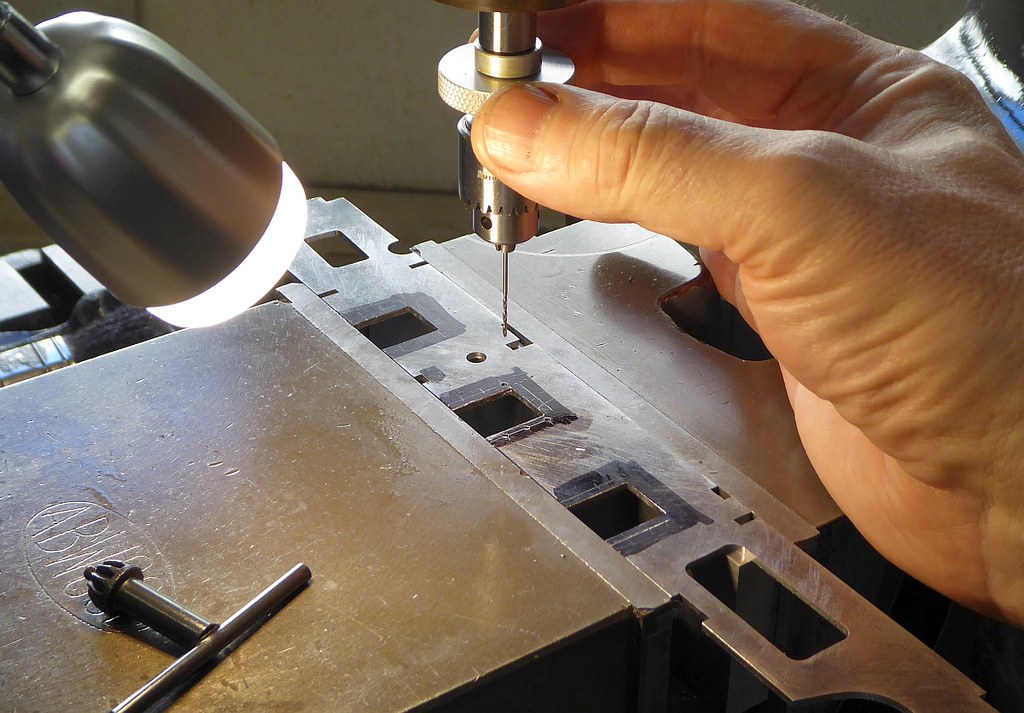

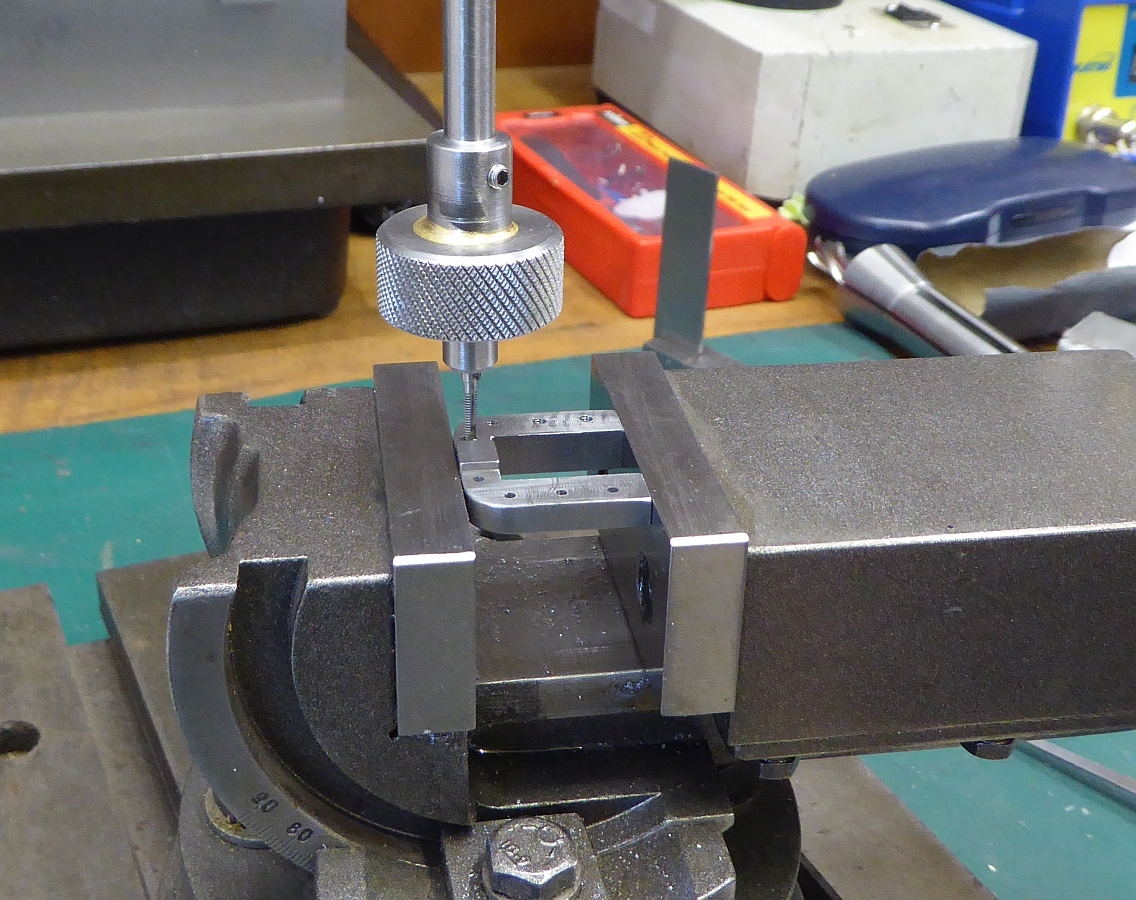

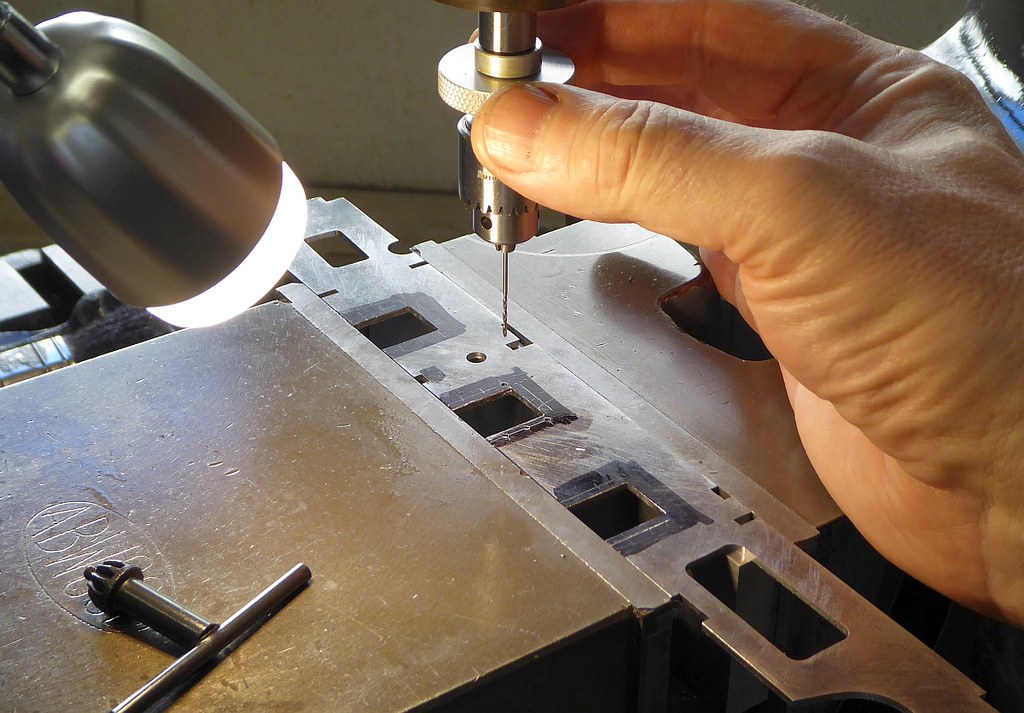

Drilling 10BA holes using Bridgeport

Sensitive drilling chuck helps...

Marking out is there just a sanity check

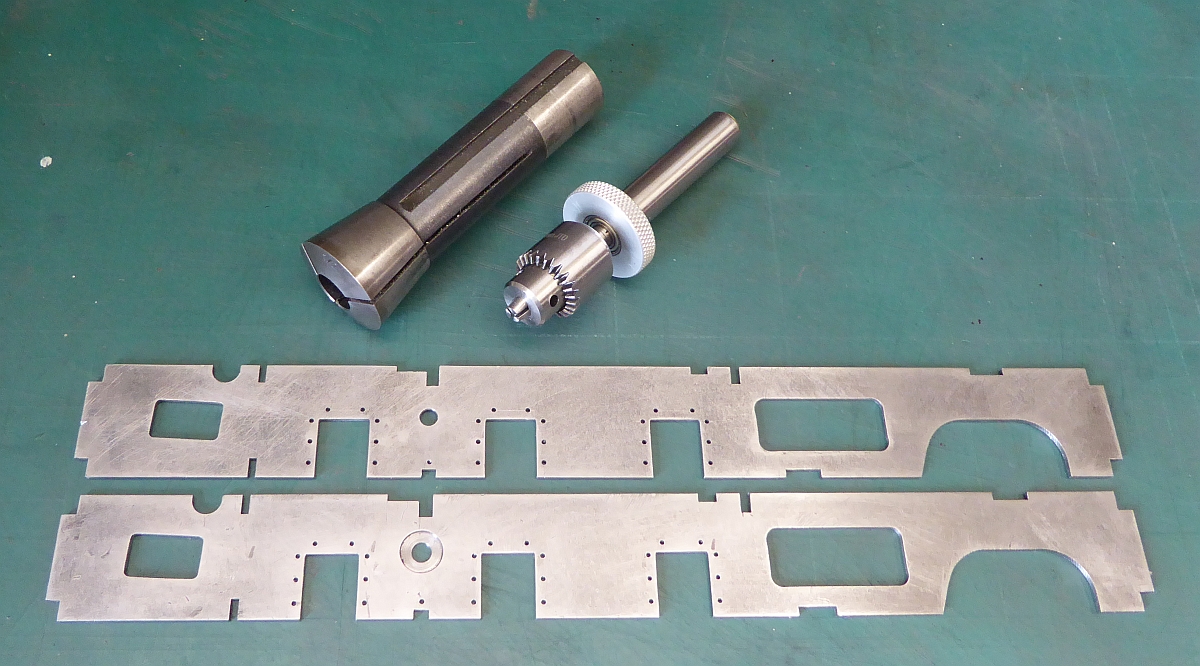

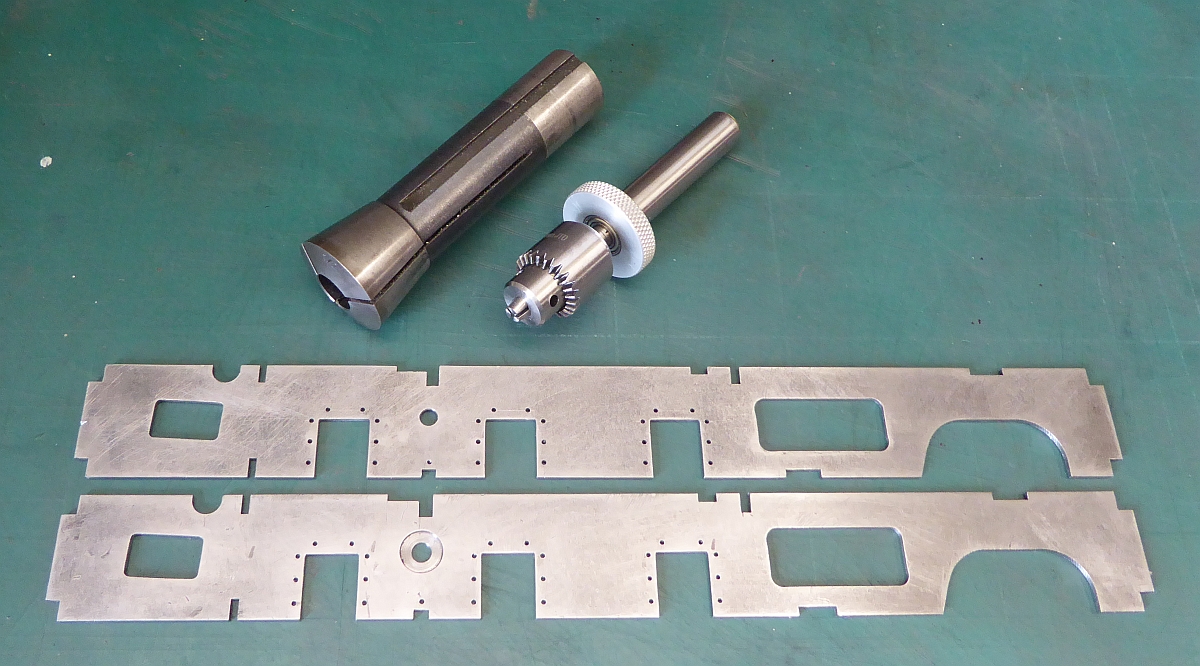

Here, frames and drilling atatchment next to them.

It fits in 1/2" collet and allows me to use milling machine's digital readout.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 2:55 pm

by bambuko

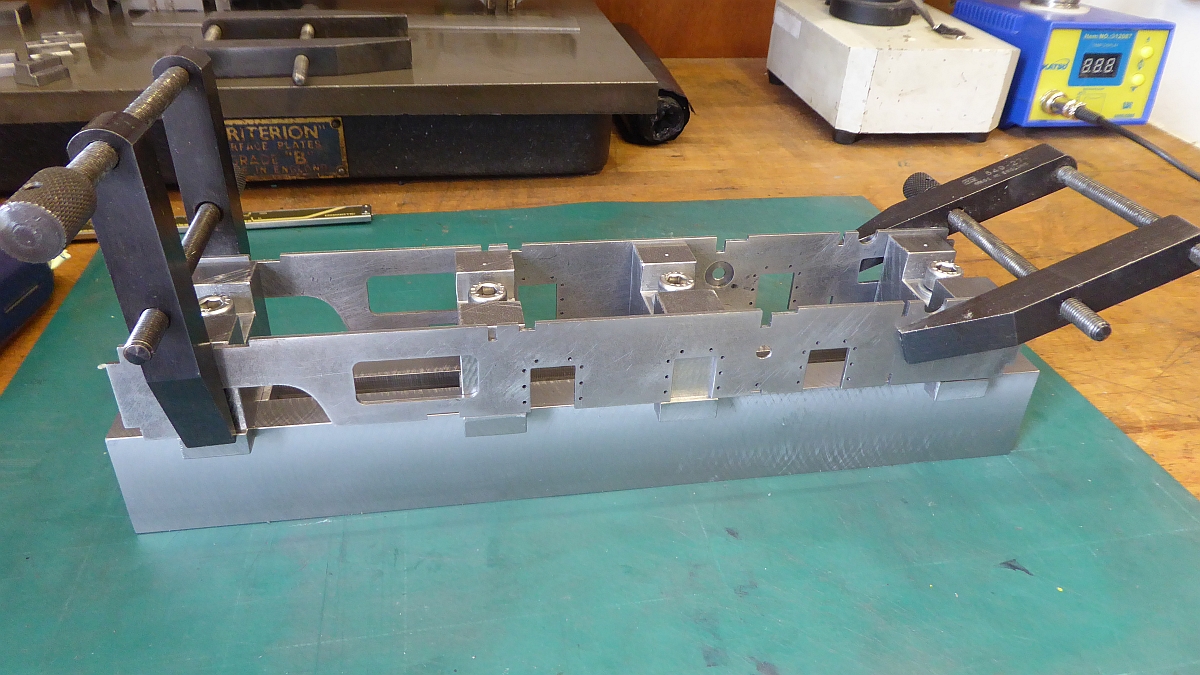

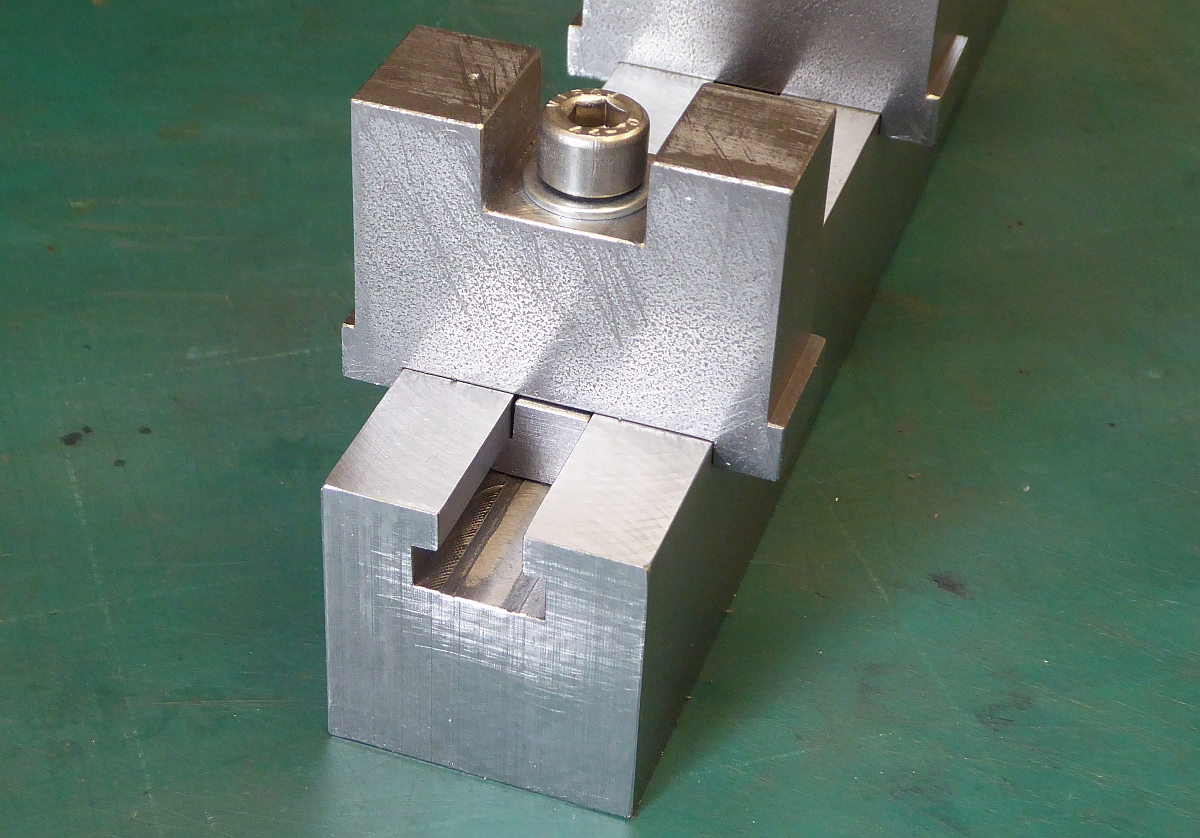

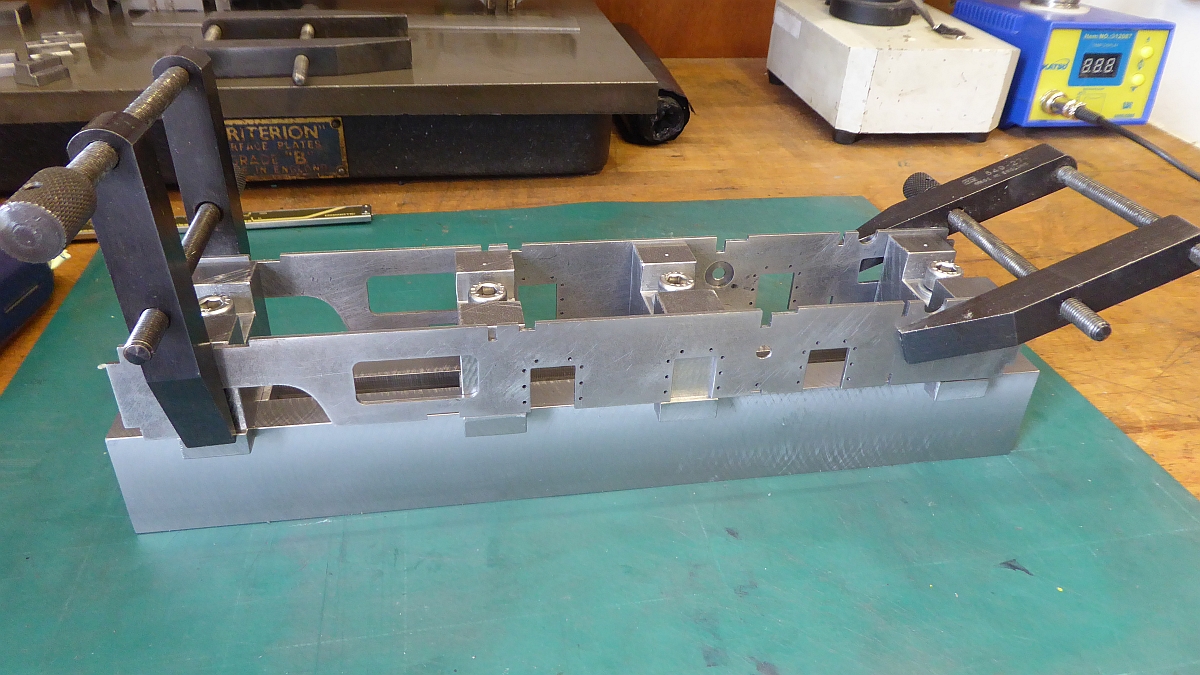

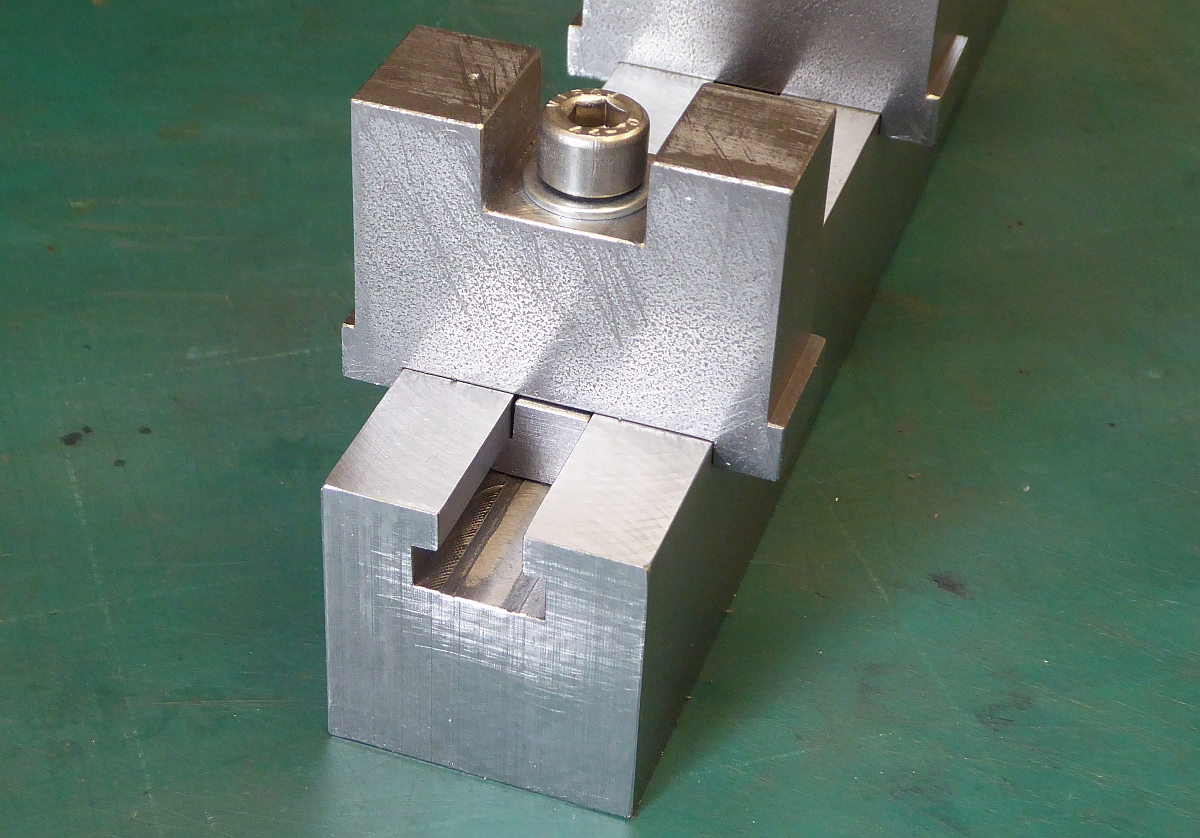

I plan to braze frames together (as recommended by LBSC), using assembly/brazing fixture:

and from another angle:

Of course, it wouldn't make sense to produce this jig just for one loco, so it is made adjustable, can be used (with other parts) for inside as well as outside frames and different locos etc, etc.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 3:13 pm

by IanC

That's very impressive.

I wish I had the skill and tools to scratch build.

I shall follow this with interest.

Ian

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 10:22 pm

by Hydrostatic Dazza

Sweet, there are some sweet features in your build.

I will enjoy following this build, Please keep us fed with pics and commentary.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Mar 26, 2018 10:27 pm

by tom_tom_go

Equally impressed, looking forward to future updates.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Mar 27, 2018 10:16 am

by daan

And another metalworking wizard.. Very nice! I love the CAD drawings, they give a nice idea of how the loco will look like and help as guidance to match the work with the drawing from about every angle possible. Aonther thread to follow.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Mar 27, 2018 10:45 am

by bambuko

Thank you for your encouragement guys

Will try not to dissapoint with updates, but they are likely to be less frequent than some here...

It is not ready made design, so I am sure there will issues that will hamper the progress, plus I am very slow worker

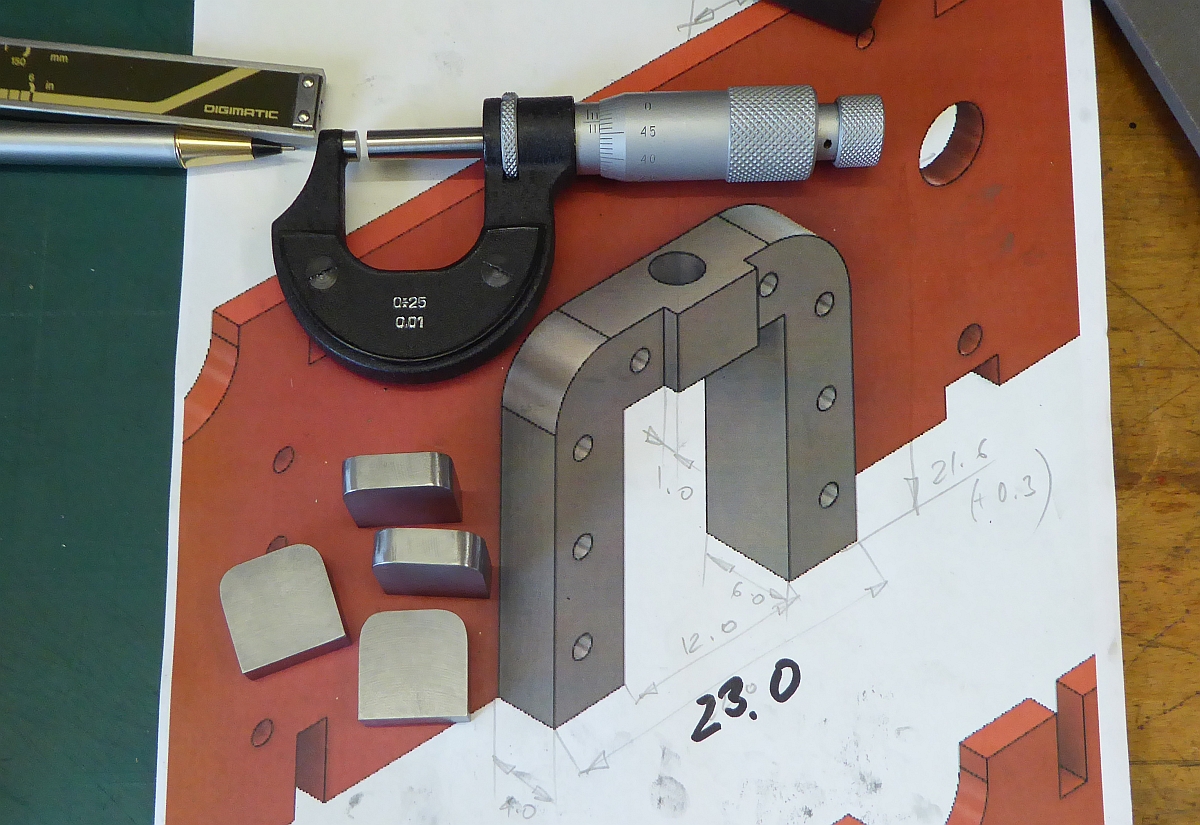

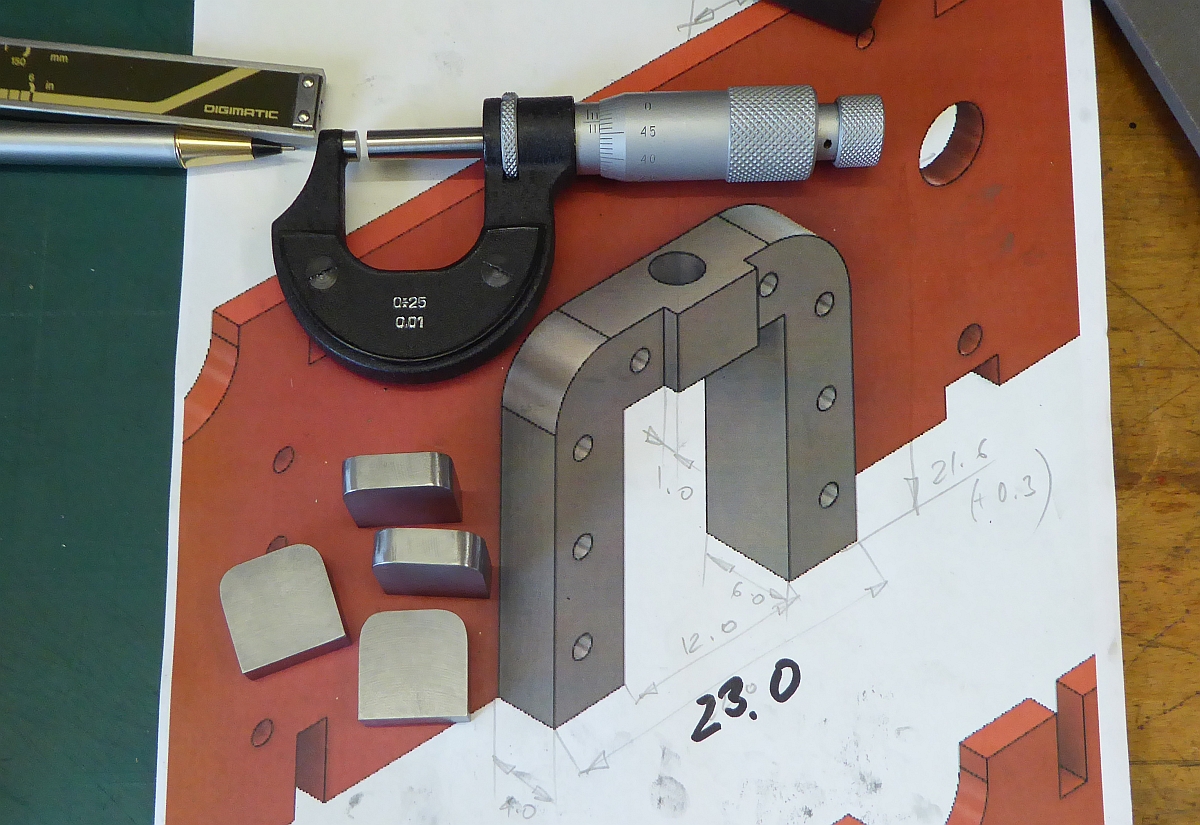

Next will be the hornblocks. They are very simplied and purely functional, but not really visible from outside so I am OK with it.

These are front hornblocks for the two equalised axles.

As you will see, most of the time I do not bother creating drawings

I am planning to use 10BA hex bolts to secure hornblocks to frames (all secured with Loctite), but regular 10BA hexagon looks huge, so I have ordered 10 BA bolts with one size smaller (12BA) heads.

These come from:

https://www.ekpsupplies.com/steel-one-s ... crews.html

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Mar 27, 2018 5:31 pm

by daan

Just a little thing to add to the CAD drawings. I came across

this on the web, where the CAD drawings are used as a base for 3d printing the difficult parts. It is used where normally one would use castings.. May be it's an idea for anyone homebuilding locomotives?

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Mar 27, 2018 5:52 pm

by bambuko

Yes indeed - this is one way, particularly where appearance of finished part matters and one off castings are not available or not economical.

Some parts are easy to fabricate, others not so...

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Wed Mar 28, 2018 10:46 am

by bambuko

Bolts from EKP arrived next day - happy customer.

They are 2.5mm AF instead of the standard 10BA being 3mm AF.

Not much, but to me - worth it (I know emphasis here is on having fun rather than rivet counting

or hex sizing

. but I like it, so...)

Here the comparison:

I took two middle screws from another (G1) model and replaced 10BA with 12BA hex (both are 10BA thread).

Close ups like this are brutal

- need to do more finishing

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Wed Mar 28, 2018 2:03 pm

by tom_tom_go

I can appreciate this as I am anti-CSK screws where they are not needed!

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Wed Mar 28, 2018 10:05 pm

by Hydrostatic Dazza

On the Subject of BA screws, the quality varies a lot, which is very annoying. I have various 10BA screws that measure from 1.62mm to 1.68 over the crests which presents problems of loose fits and possible stripped/damaged female threads. I seek the answer for a consistent quality supply.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Thu Mar 29, 2018 9:43 am

by bambuko

As far as I know BS93 tolerance for 10BA is 1.675 max and 1.605 min.

So the numbers you quote are within tolerance.

My 10BA (both old stock from un-known source and latest from EKP) measure 1.65

I haven't checked them all, just a few.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Fri Mar 30, 2018 9:35 am

by FWLR

Great thread, impressed with your work. there was a quote I read only this morning from a site ( just can’t remember which one)

But this is what I read.

Rule 1. Keep the gauge alive. (I think)

Rule 2. There are no rules.

You are so right, it’s your build…..

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Sun Apr 01, 2018 1:41 pm

by bambuko

Thank you @

FWLR

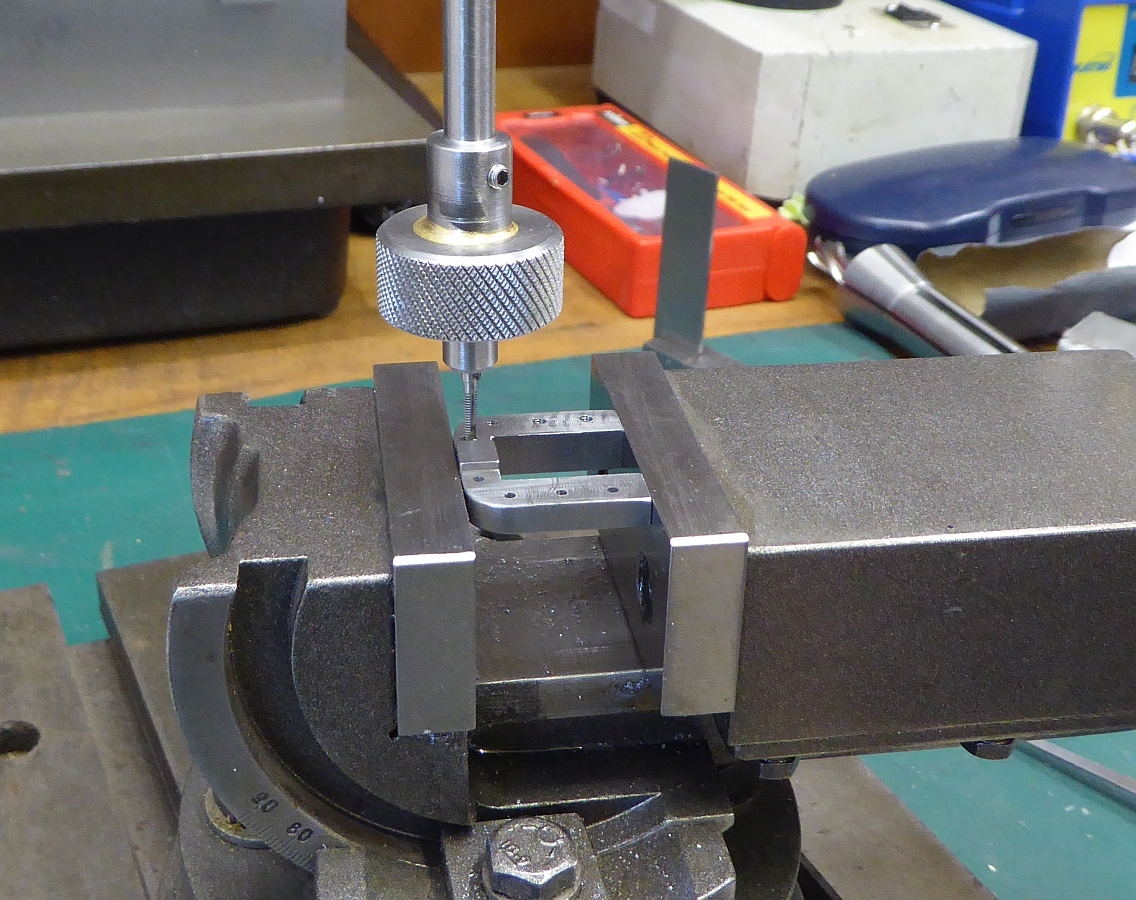

Managed to get some work done... front hornblocks temporarily secured to frames for drilling (and later tapping 10 BA)

At this stage axlebox opening in the hornblocks are undersize (metal on), with final machining to size to be done after the frames are brazed and hornblocks are bolted and Loctited to the frames (we shall see how this theory works in practice...

)

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Apr 02, 2018 7:29 pm

by bambuko

Today, spent a lot of time tapping the holes in hornblocks:

An exercise in patience

, with occasional clenched buttocks

32 holes tapped, 16 more to do on rear hornblocks, plus 12 for keeps...

I reckon I will be sick of small thread tapping for a while

Here the results:

BTW next to the tap holder is homemade 12 BA socket (better

than commercially available ones afaiac)

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Mon Apr 02, 2018 7:53 pm

by tom_tom_go

Excellent work, I can only marvel at your skills.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Apr 03, 2018 7:07 am

by FWLR

I agree, that’s some very nice skill being shown.

Re: bambuko loco works 0-6-2 (Fowler)

Posted: Tue Apr 03, 2018 2:37 pm

by bambuko

You are far too generous guys

Glad you enjoy it! - thank you for your kind comments.

The idea is that with three axles without suspension of some kind, only two axles at best give you some traction. It's probably un-necessary complication (as proven by countless 16mm locos) but it is my railway, so whatever rocks my boat goes

The idea is that with three axles without suspension of some kind, only two axles at best give you some traction. It's probably un-necessary complication (as proven by countless 16mm locos) but it is my railway, so whatever rocks my boat goes

)

)