Page 33 of 46

Re: Llewellyn Loco Works #1

Posted: Mon Jan 04, 2021 9:29 am

by FWLR

MAM is learning a lot from a master engineer... Looking forward to seeing progress on her build Dazza.

Re: Llewellyn Loco Works #1

Posted: Tue Jan 05, 2021 9:23 pm

by Hydrostatic Dazza

FWLR wrote: ↑Mon Jan 04, 2021 9:29 am

MAM is learning a lot from a master engineer... Looking forward to seeing progress on her build Dazza.

I am not so sure about the "master engineer" , I simply read a lot, learn from others and try to apply good stuff to what we do.

I will keep all posted on progress. MAM was doing some clean up work last night and tonight we may be doing some plate work soldering.

MAM's loco runs very sweet, 30 -35mins at a realistic speed and very stable with its SloMo. Due to Roundhouse motion having a decent amount of slop and play when I set the valves I optimised it for forward running, We can get it to creep around the POR with out fuss. Very soothing. It works fine in reverse but I can detect a difference, but it is not significant

Re: Llewellyn Loco Works #1

Posted: Wed Jan 06, 2021 10:55 am

by pandsrowe

That's a very good looking set of bending rolls there Daz and indispensable for jobs like this, are they a home brew construction or perhaps something made for the jewellery trade?

Re: Llewellyn Loco Works #1

Posted: Wed Jan 06, 2021 12:37 pm

by GTB

pandsrowe wrote: ↑Wed Jan 06, 2021 10:55 am

That's a very good looking set of bending rolls there Daz and indispensable for jobs like this, are they a home brew construction or perhaps something made for the jewellery trade?

They are made for hobby use and are available here in Oz from suppliers of hobby tools. Mine came from a tool stall at a local exhibition in Melbourne. From memory it was the plastic kit modellers show, but I've seen them at model railway shows as well.

Chronos has them in the UK, catalogued as a 'miniature bending machine' and I assume other model engineering suppliers would also sell them.

I bought mine years ago for HO use and don't use it often in garden scale as it's small size limits it to small and thin parts. I've got a 3 in 1 sheet metal machine which is a combination of bending rolls/bending brake/guillotine that gets a lot more use for loco building, especially the guillotine.

Regards,

Graeme

Re: Llewellyn Loco Works #1

Posted: Wed Jan 06, 2021 9:21 pm

by Hydrostatic Dazza

What Graeme said, and good for preforming Peco SM32 rail to ensure kink free joins and smooth curves, nice transitions into curves after some wee groves are machined at one end of the rollers

Re: Llewellyn Loco Works #1

Posted: Thu Jan 07, 2021 2:23 am

by Old Man Aaron

Makes a damn-sight better rail bender than my old temporary bodge-up.

That was for de-twisting and straightening reclaimed rail from my first line..

- IMG_3754.JPG (248.22 KiB) Viewed 4610 times

Great work as always. There's a unique elegance to 19th century, well, anything; which is nice to see incorporated in the garden scales.

Re: Llewellyn Loco Works #1

Posted: Fri Jan 08, 2021 8:12 pm

by Hydrostatic Dazza

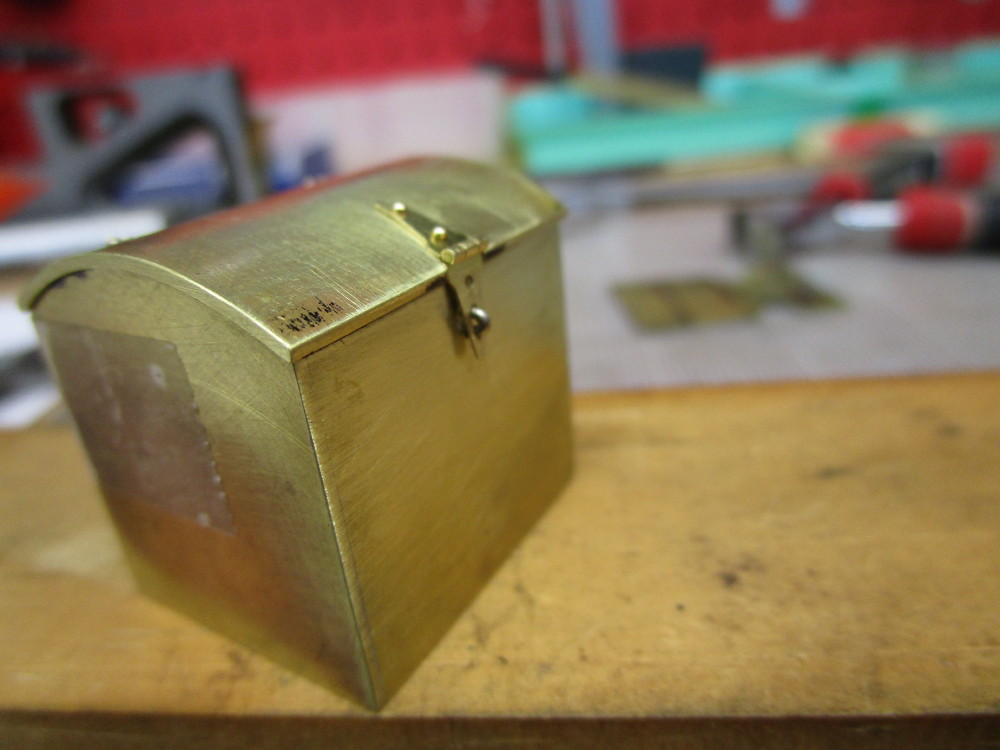

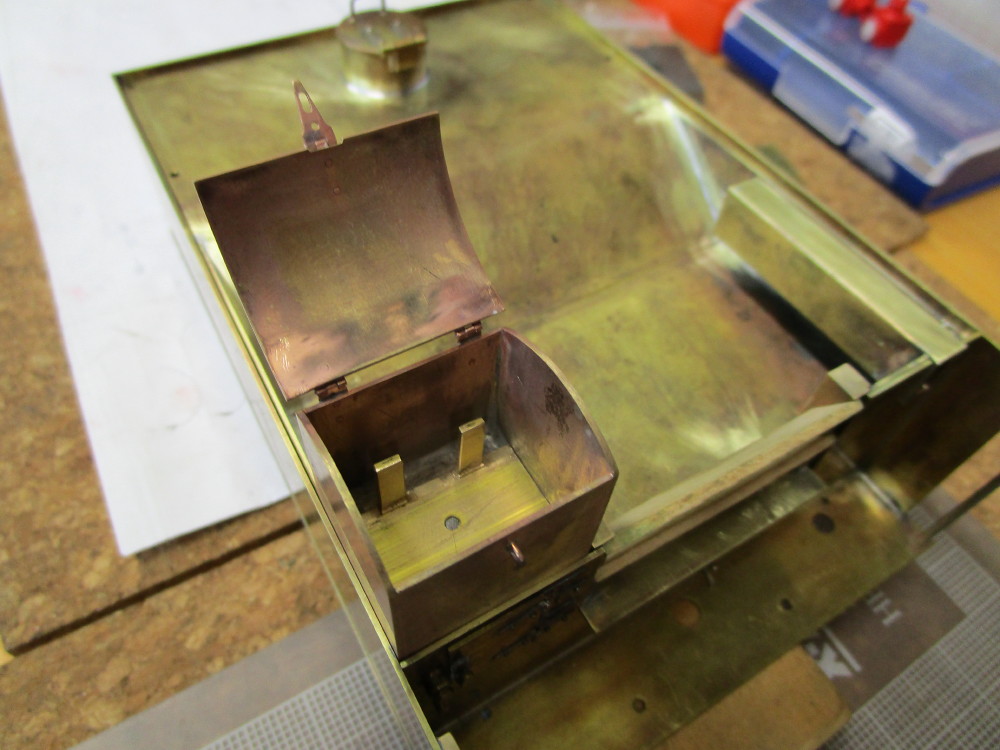

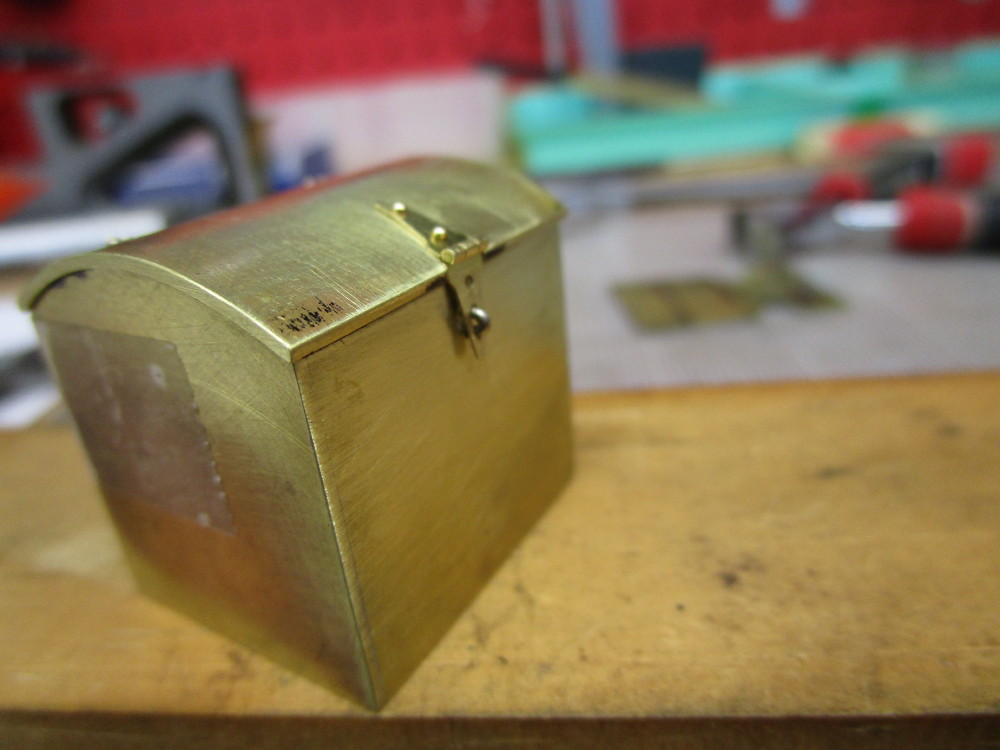

Weekend plans changed, but plenty to keep one occupied in the Red Room, so yesterday arvo working on the lamp locker for the loco, filing a 0.80mm slot into the hinge for the latch was tricky. I will be soldering these parts today.

Re: Llewellyn Loco Works #1

Posted: Sat Jan 09, 2021 8:06 am

by FWLR

Superb workmanship there Dazza.

Put a couple of straps along the top and around the box and you will have a Pirates Chest....

Re: Llewellyn Loco Works #1

Posted: Sat Jan 09, 2021 9:19 pm

by ge_rik

Amazing attention to detail, Dazza.

So impressed!

Rik

Re: Llewellyn Loco Works #1

Posted: Tue Jan 12, 2021 8:10 am

by FWLR

Thats very neat work Dazza.

It must of been a real pain though.

It will be well worth it when you have finished it I'am sure.

Re: Llewellyn Loco Works #1

Posted: Tue Jan 12, 2021 8:02 pm

by Hydrostatic Dazza

FWLR wrote: ↑Tue Jan 12, 2021 8:10 am

Thats very neat work Dazza.

It must of been a real pain though.

It will be well worth it when you have finished it I'am sure.

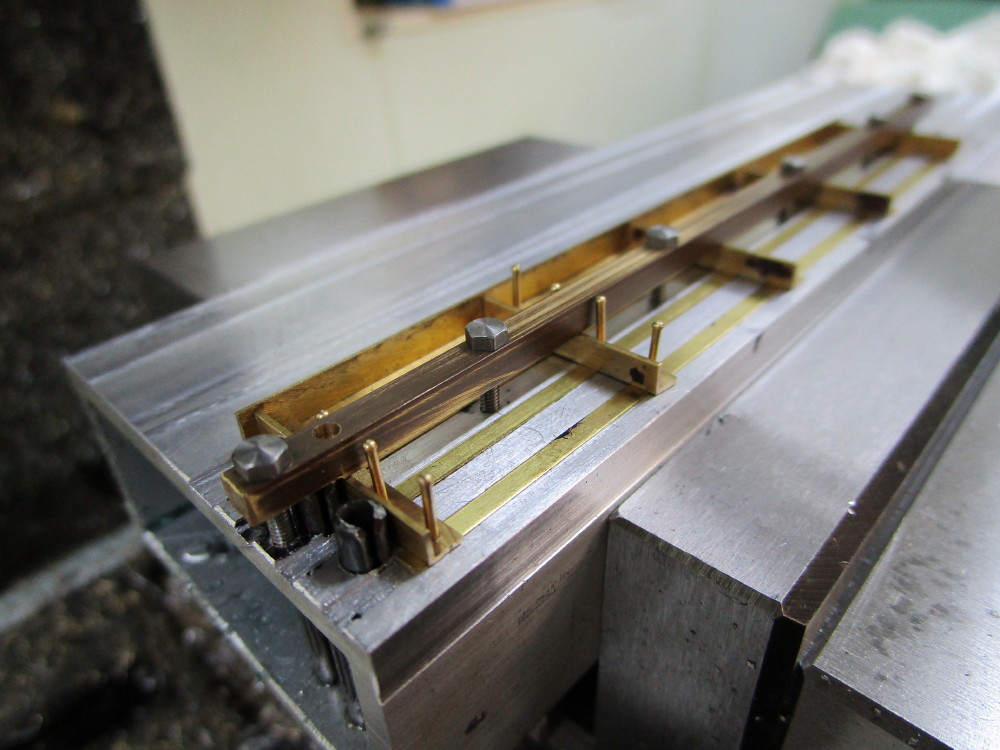

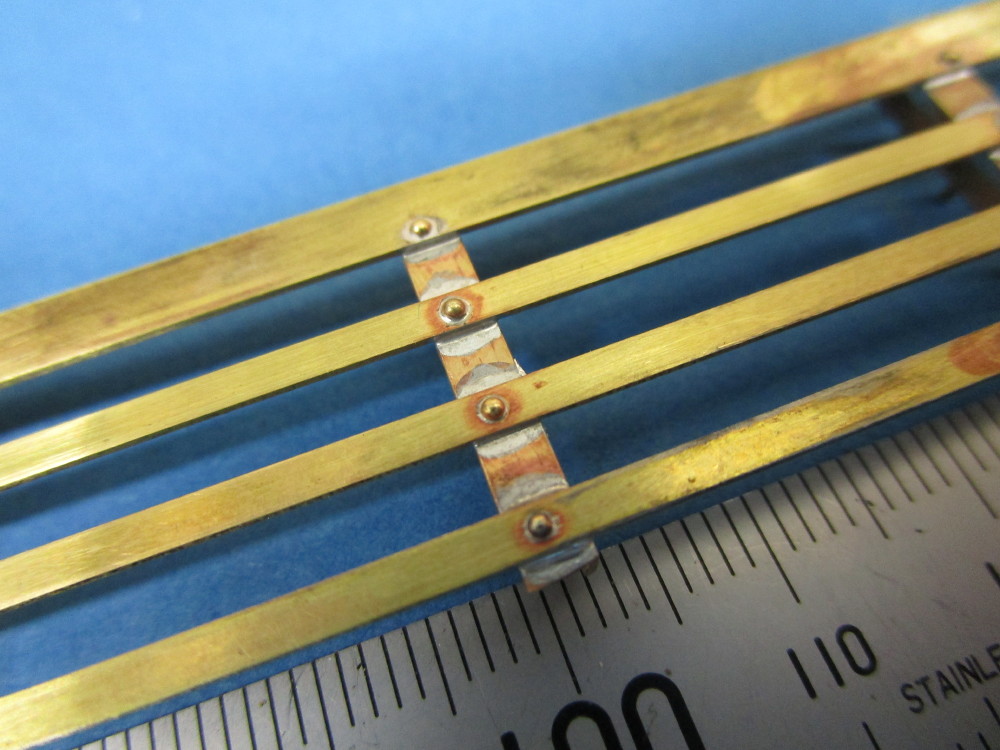

Thanks Rod, I am not peening the rivets over, simply soldering but it took a while and going up the wrong path and gong back and trying again. I think I have it sussed out, but I will be relieved when they are attached to the tender. Two more of these to do and cook up with solder. A ways to go yet

Re: Llewellyn Loco Works #1

Posted: Thu Jan 14, 2021 8:28 pm

by Hydrostatic Dazza

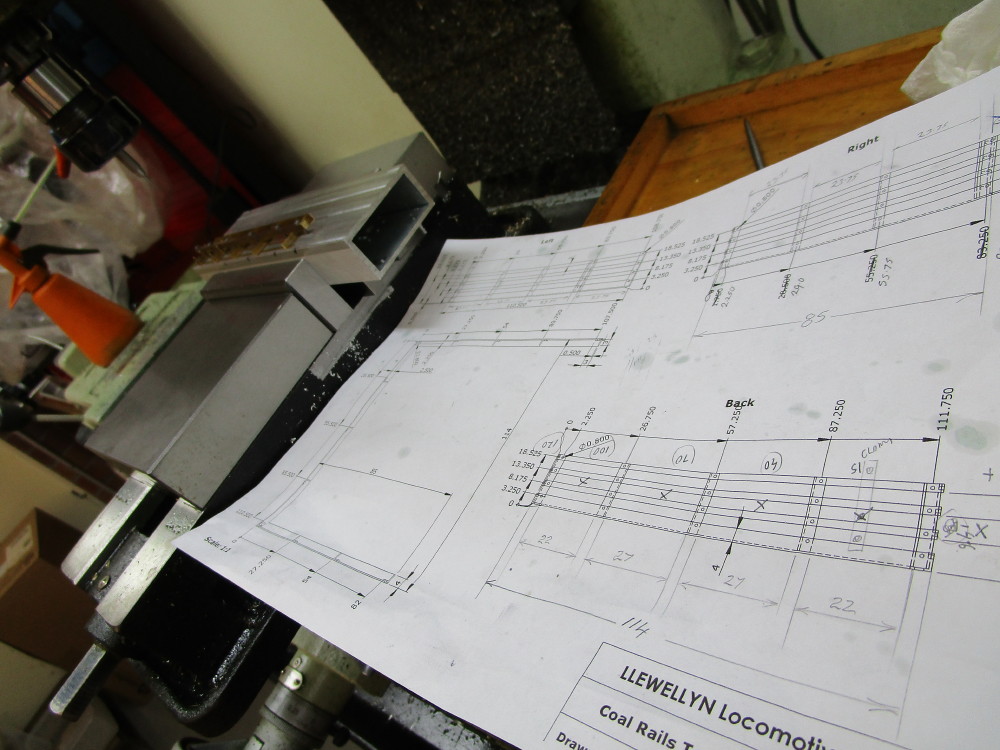

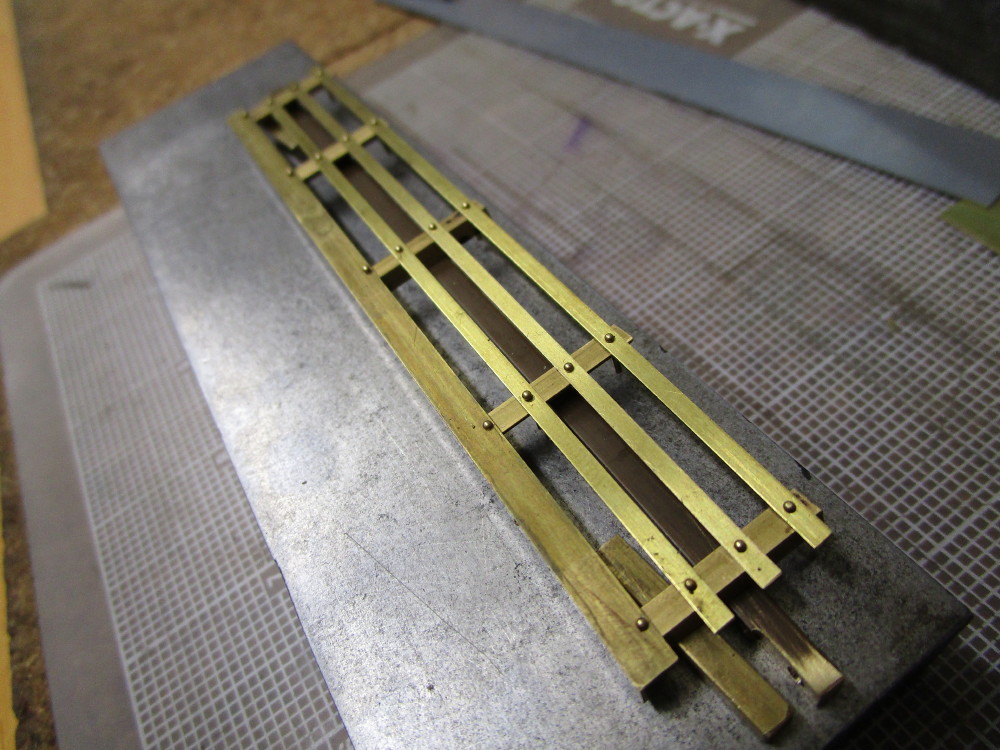

The right hand side is done and it went smooth. Crikey that took some time but getting the process and fixture sorted is the time sink, now to solder up, neatly I hope.

The thing with such items is if they are not accurate, straight and neat they will look dreadful.

Re: Llewellyn Loco Works #1

Posted: Fri Jan 15, 2021 7:54 am

by FWLR

They do look very nice Dazza, it would be a shame to ruin them by rushing it. But I know your standard of work is excellent so I don't think you will have any worries there.

There is one thing I have spotted though, the smaller of the rails looks like the rail second from the bottom is slightly longer. Or is it an optical illusion...

Re: Llewellyn Loco Works #1

Posted: Fri Jan 15, 2021 8:40 pm

by Hydrostatic Dazza

FWLR wrote: ↑Fri Jan 15, 2021 7:54 am

They do look very nice Dazza, it would be a shame to ruin them by rushing it. But I know your standard of work is excellent so I don't think you will have any worries there.

There is one thing I have spotted though, the smaller of the rails looks like the rail second from the bottom is slightly longer. Or is it an optical illusion...

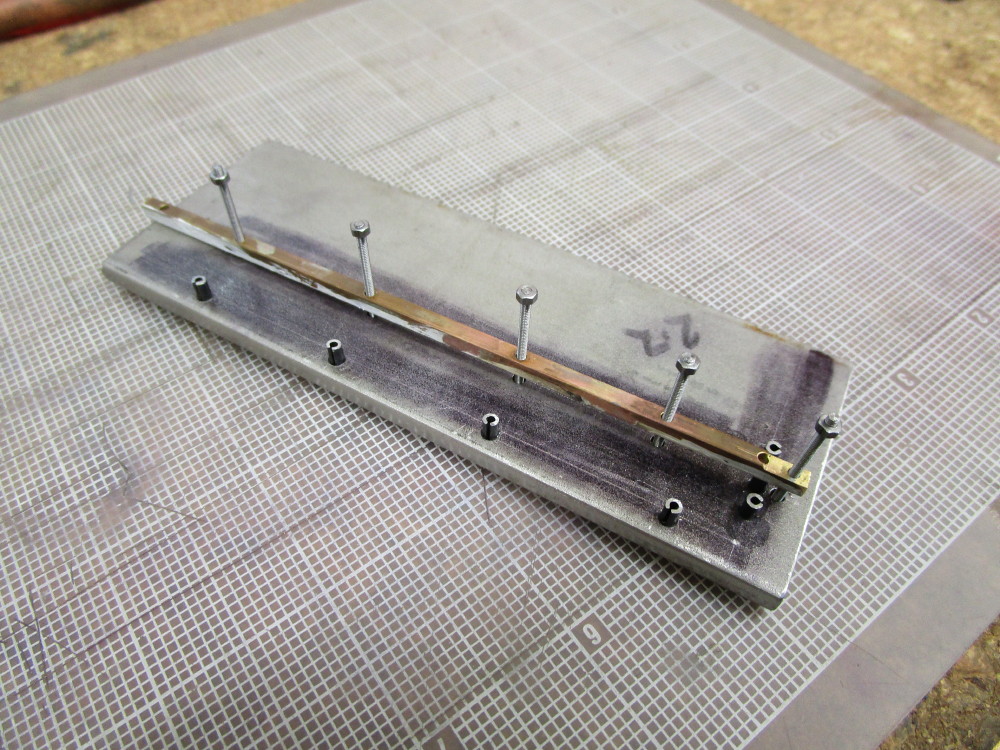

You're right, but they are all over length, to trim later when soldered up and also to get the over lap on the other side rails to meet nicely around the 90 degree corner.

Speaking of soldering, my first solder attempt on the coal rails was a complete failure. I stopped before too much damage was done. The flux reacted badly with the aluminum jig even though the material was a wee bit proud of the alloy. The flux went to yuk. I am off to the Rattler this arvo for just one shift and back tonight so tomorrow I will make a simple soldering jig from stainless scrap and have another go. I was rather disappointed but I kept saying I learnt a lot last night and I know how to fix this....I have one rail and one upright to remake tomorrow, that shall not take too long. Jig making and then cleaning and setting up again takes time.

Re: Llewellyn Loco Works #1

Posted: Sat Jan 16, 2021 9:54 am

by FWLR

Well I know that in the end you will have a model that will surpass any you could buy...