Page 32 of 46

Re: Llewellyn Loco Works #1

Posted: Fri Nov 20, 2020 7:51 pm

by Hydrostatic Dazza

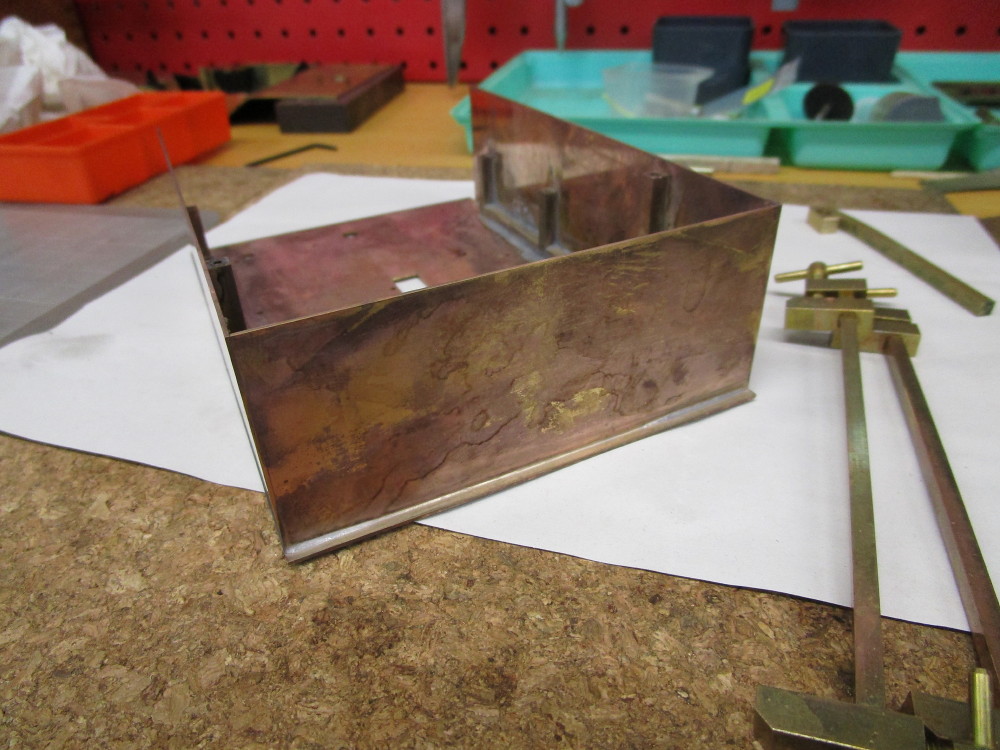

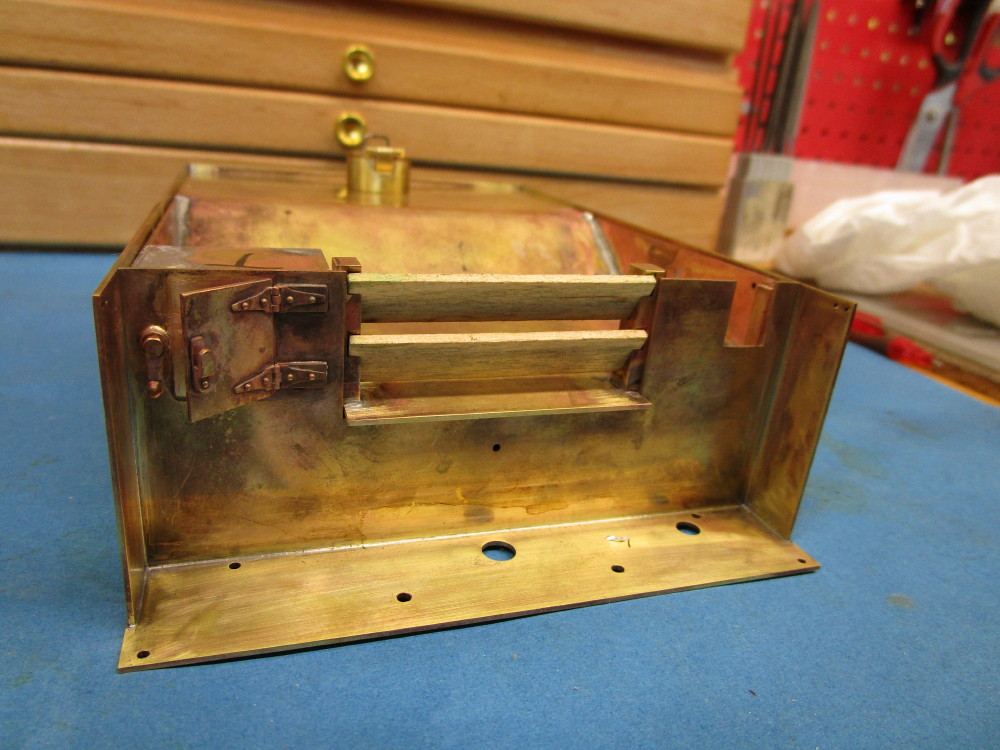

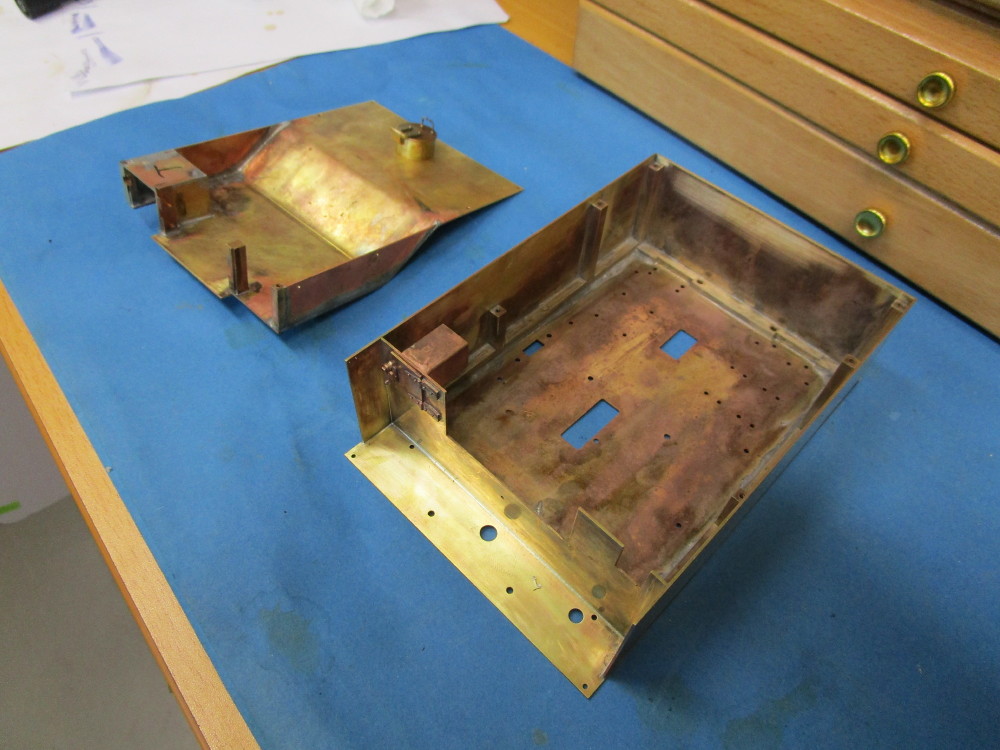

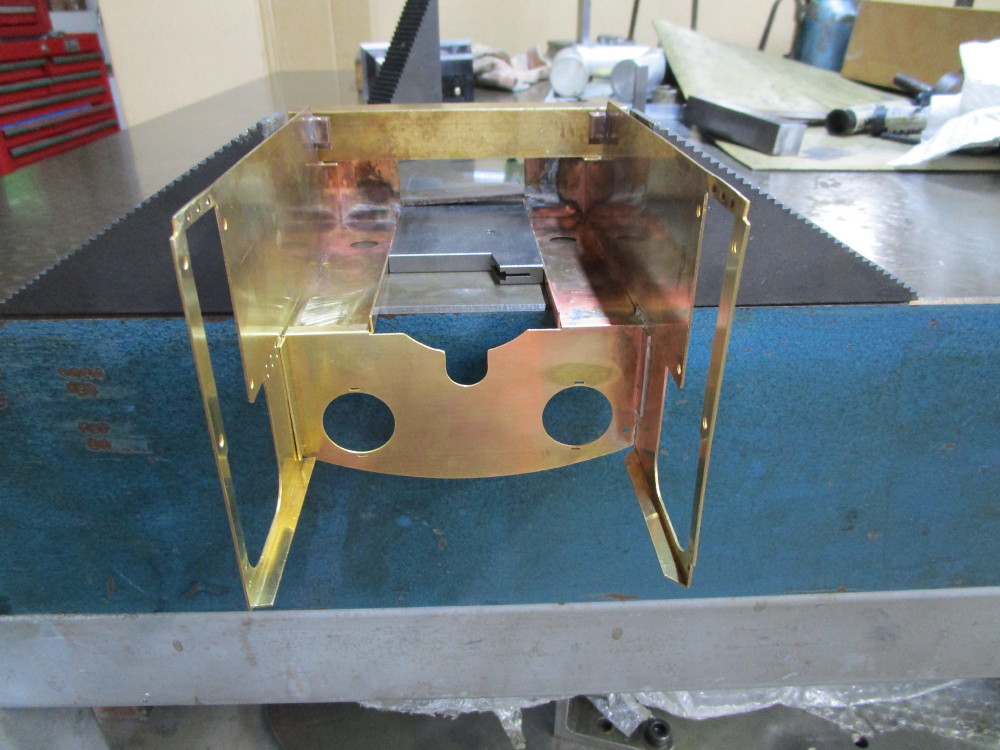

Getting closer to soldering up the tender tank.

Re: Llewellyn Loco Works #1

Posted: Sat Nov 21, 2020 9:36 pm

by Hydrostatic Dazza

"This soft soldering caper is strange compared to silver brazing eh Shaun."

Re: Llewellyn Loco Works #1

Posted: Mon Nov 23, 2020 9:04 am

by FWLR

That looks absolutely brilliant Dazza. Very clean and neat I think. Well done....

Re: Llewellyn Loco Works #1

Posted: Mon Nov 23, 2020 1:38 pm

by Garethh

Some lovely work there! Soft soldering a bit different to brazing steel with brass isn’t it!

Re: Llewellyn Loco Works #1

Posted: Mon Nov 23, 2020 7:52 pm

by Hydrostatic Dazza

Garethh wrote: ↑Mon Nov 23, 2020 1:38 pm

Some lovely work there! Soft soldering a bit different to brazing steel with brass isn’t it!

I still silver braze some brass bits with silver. I silver braze my frame tubes with 56% Harris silver. Brass is only used now on the cutout piece in my chainstay bridges, but I do brass brass frames for years before switching to Silver 20 years ago. Just getting one's head around the fact that the material gets barely warm and the soft solder runs after all the years of brazing. It feels like one is cheating when using soft solder.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 24, 2020 6:37 am

by Garethh

Hydrostatic Dazza wrote: ↑Mon Nov 23, 2020 7:52 pm

Garethh wrote: ↑Mon Nov 23, 2020 1:38 pm

Some lovely work there! Soft soldering a bit different to brazing steel with brass isn’t it!

I still silver braze some brass bits with silver. I silver braze my frame tubes with 56% Harris silver. Brass is only used now on the cutout piece in my chainstay bridges, but I do brass brass frames for years before switching to Silver 20 years ago. Just getting one's head around the fact that the material gets barely warm and the soft solder runs after all the years of brazing. It feels like one is cheating when using soft solder.

I’ve only ever used silver on frames for stainless bits and pieces, I can definitely see how it’d work better when doing a lot of lug work though. I found I was hopeless trying to use a soldering iron to soft solder, a small butane torch seemed much more natural!

Re: Llewellyn Loco Works #1

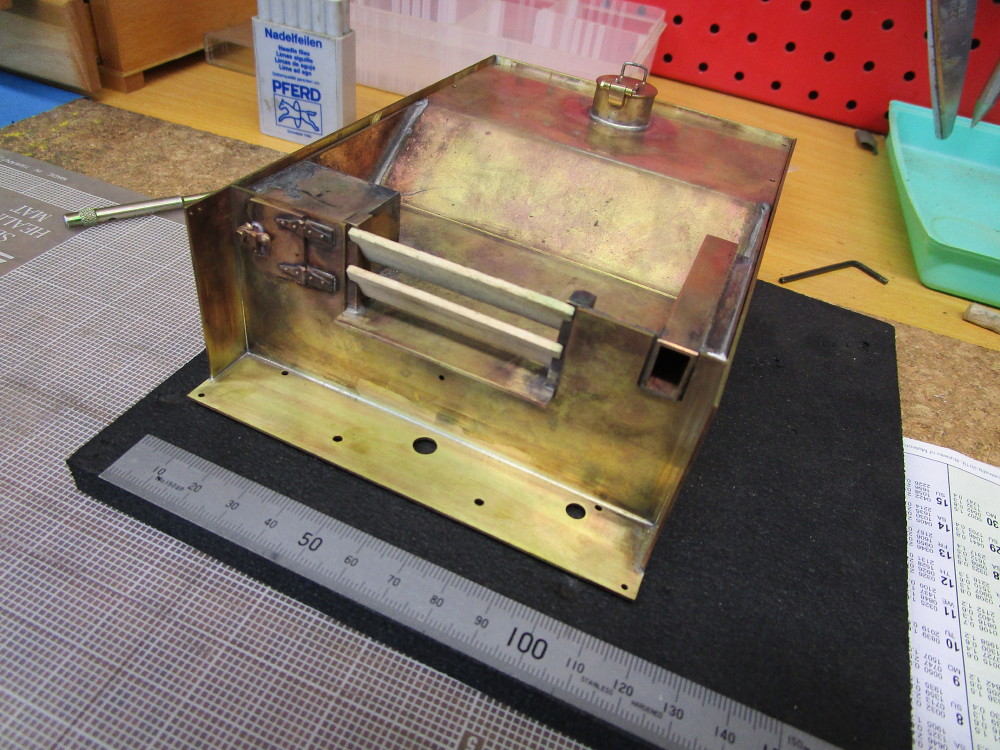

Posted: Wed Dec 30, 2020 8:54 pm

by Hydrostatic Dazza

Re: Llewellyn Loco Works #1

Posted: Thu Dec 31, 2020 1:55 am

by Old Man Aaron

Extremely tidy work there.

Re: Llewellyn Loco Works #1

Posted: Sun Jan 03, 2021 9:20 pm

by Hydrostatic Dazza

MAM in the Red Room working on her Lady Ann plate work.

Re: Llewellyn Loco Works #1

Posted: Sun Jan 03, 2021 9:24 pm

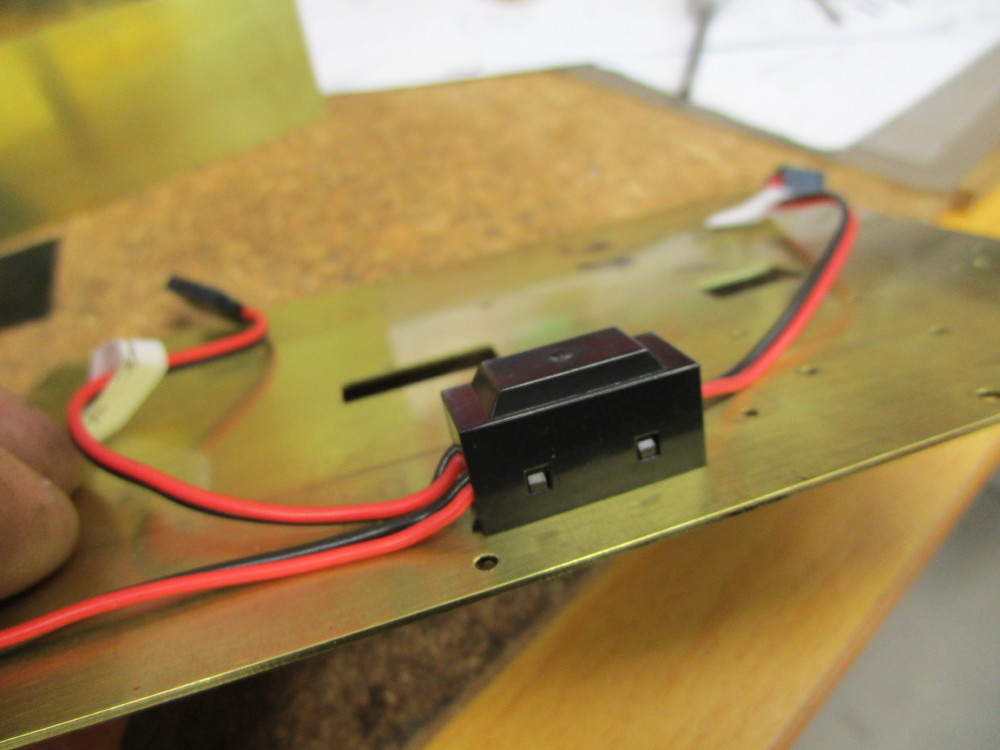

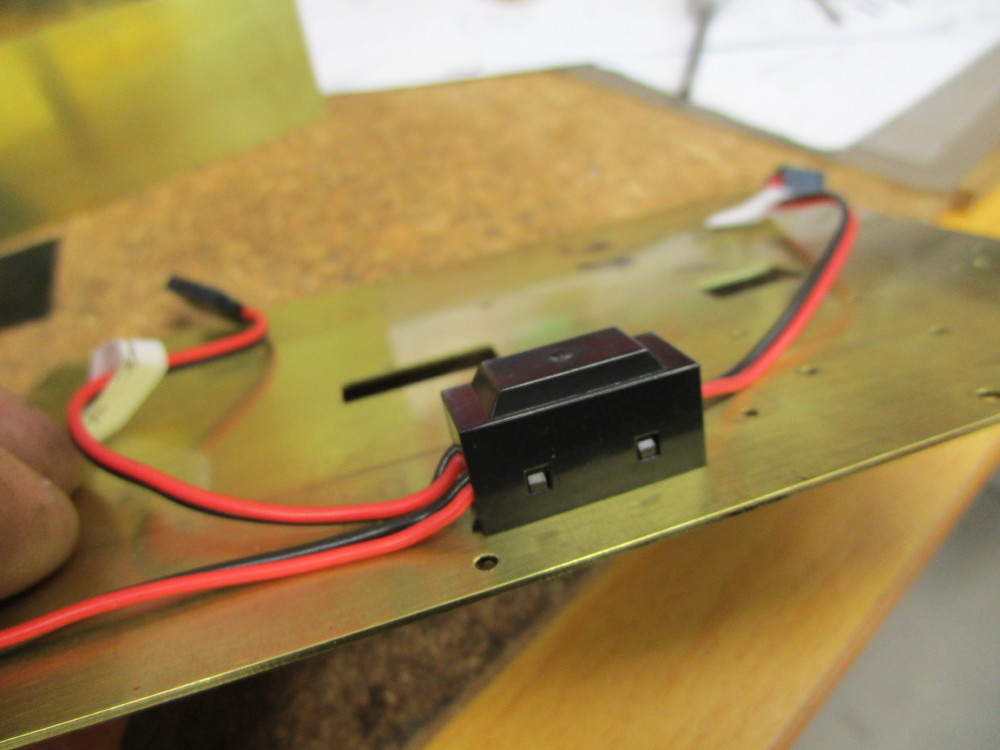

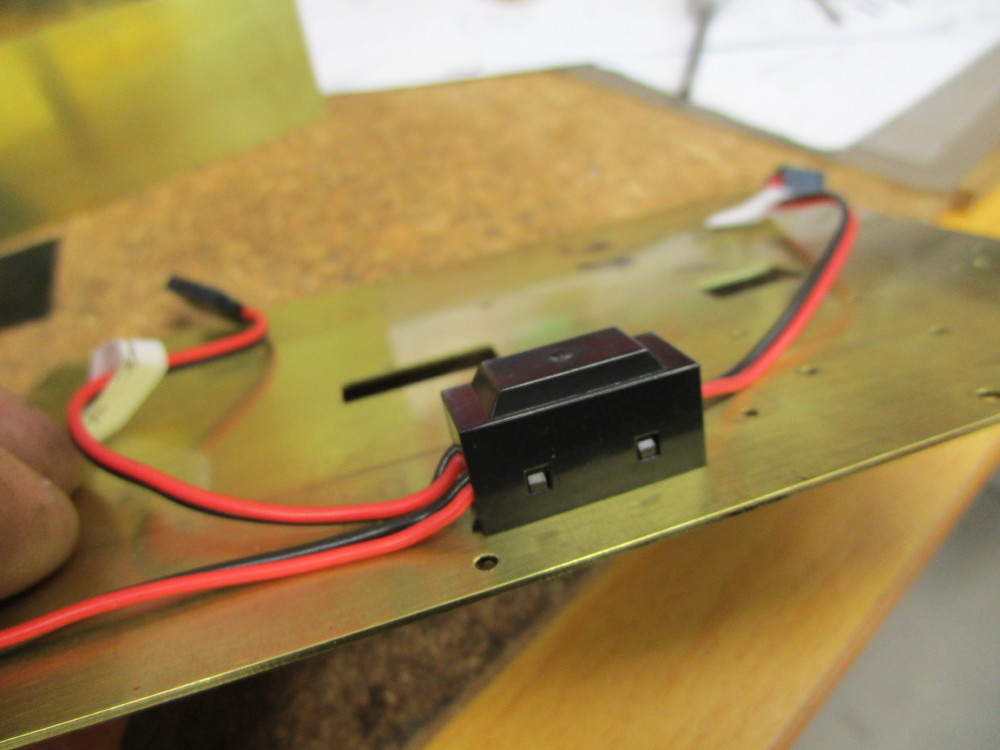

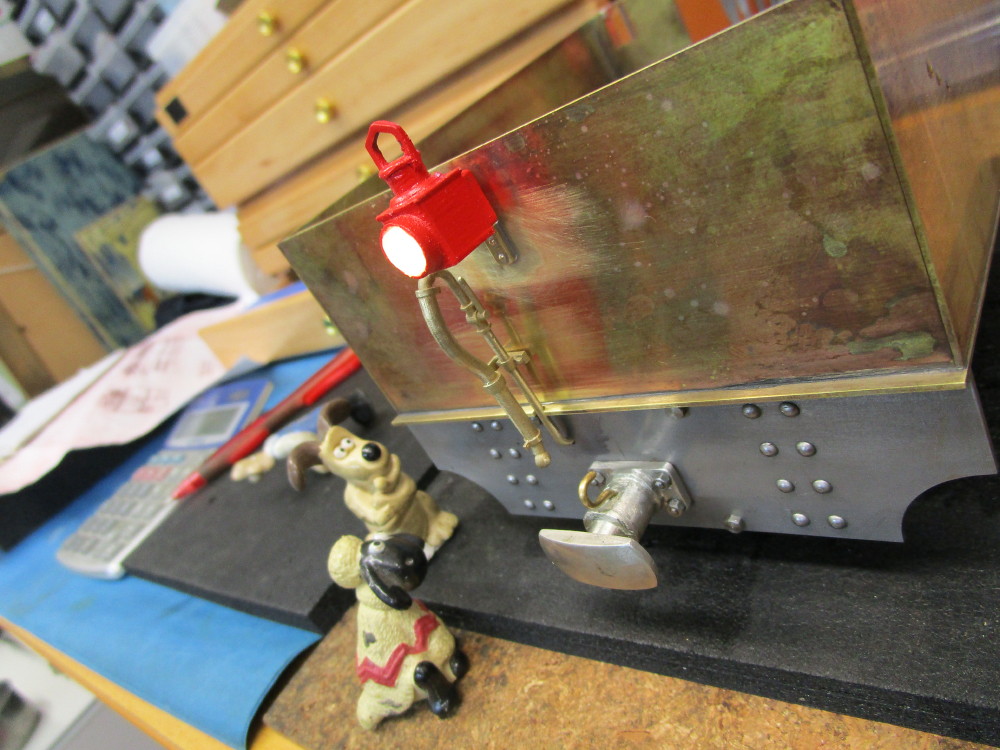

by Hydrostatic Dazza

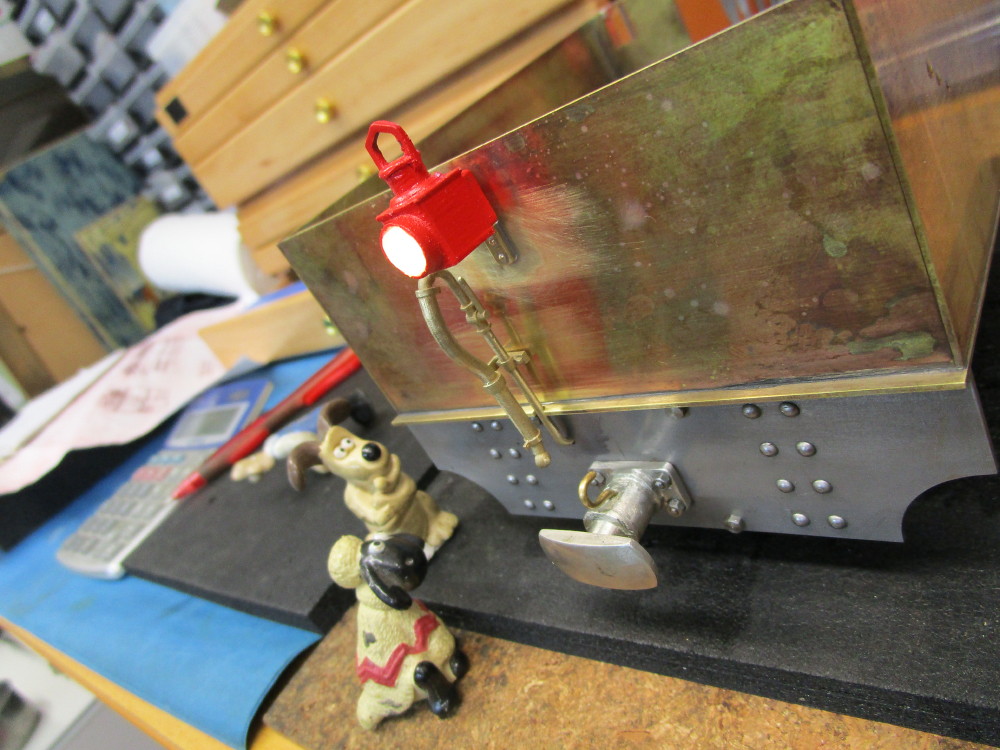

Meanwhile the mob were working on the WHB hose and machining a lamp bracket and soldering it on to the tender. A red and white SLR lamp will be stowed in a tender mounted tool box.

Re: Llewellyn Loco Works #1

Posted: Sun Jan 03, 2021 9:29 pm

by Hydrostatic Dazza

Old Man Aaron wrote: ↑Thu Dec 31, 2020 1:55 am

Extremely tidy work there.

Re: Llewellyn Loco Works #1

Posted: Mon Jan 04, 2021 9:29 am

by FWLR

MAM is learning a lot from a master engineer... Looking forward to seeing progress on her build Dazza.

Re: Llewellyn Loco Works #1

Posted: Tue Jan 05, 2021 9:23 pm

by Hydrostatic Dazza

FWLR wrote: ↑Mon Jan 04, 2021 9:29 am

MAM is learning a lot from a master engineer... Looking forward to seeing progress on her build Dazza.

I am not so sure about the "master engineer" , I simply read a lot, learn from others and try to apply good stuff to what we do.

I will keep all posted on progress. MAM was doing some clean up work last night and tonight we may be doing some plate work soldering.

MAM's loco runs very sweet, 30 -35mins at a realistic speed and very stable with its SloMo. Due to Roundhouse motion having a decent amount of slop and play when I set the valves I optimised it for forward running, We can get it to creep around the POR with out fuss. Very soothing. It works fine in reverse but I can detect a difference, but it is not significant

Re: Llewellyn Loco Works #1

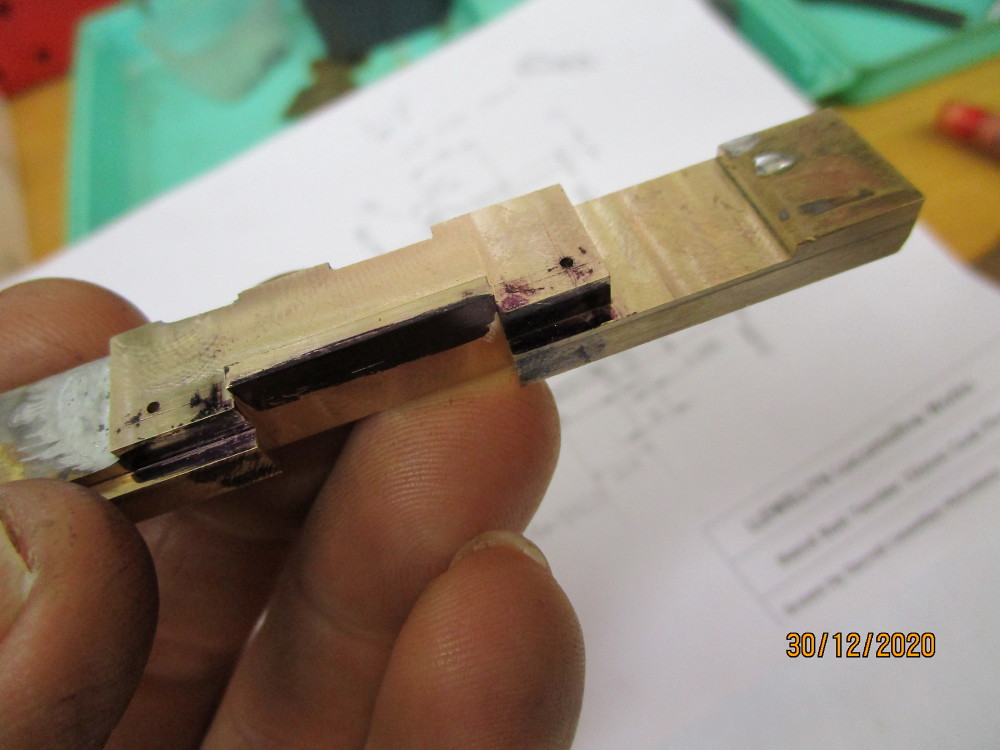

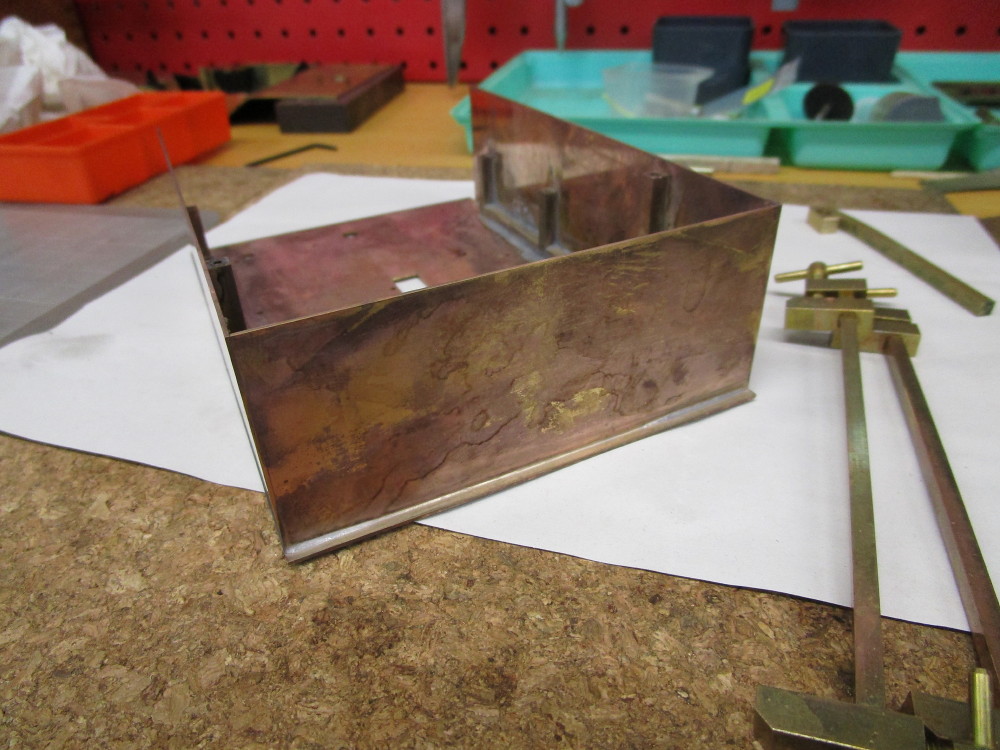

Posted: Wed Jan 06, 2021 10:55 am

by pandsrowe

That's a very good looking set of bending rolls there Daz and indispensable for jobs like this, are they a home brew construction or perhaps something made for the jewellery trade?

Re: Llewellyn Loco Works #1

Posted: Wed Jan 06, 2021 12:37 pm

by GTB

pandsrowe wrote: ↑Wed Jan 06, 2021 10:55 am

That's a very good looking set of bending rolls there Daz and indispensable for jobs like this, are they a home brew construction or perhaps something made for the jewellery trade?

They are made for hobby use and are available here in Oz from suppliers of hobby tools. Mine came from a tool stall at a local exhibition in Melbourne. From memory it was the plastic kit modellers show, but I've seen them at model railway shows as well.

Chronos has them in the UK, catalogued as a 'miniature bending machine' and I assume other model engineering suppliers would also sell them.

I bought mine years ago for HO use and don't use it often in garden scale as it's small size limits it to small and thin parts. I've got a 3 in 1 sheet metal machine which is a combination of bending rolls/bending brake/guillotine that gets a lot more use for loco building, especially the guillotine.

Regards,

Graeme