Discussion of Live Steam locomotives should be located here

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Sun Mar 11, 2018 8:55 pm

The staff at the Llewellyn Loco works have been busy, as always. The design for a new wet leg boiler is underway at the drawing office. Inspired by an article in "Australian Model Engineer" magazine.

Then there was Saturday at the Ipswich Heritage Railway Workshops and Museum for an "Association of Rail Tourism Queensland" meeting and this always involves a stroll through the workshops at the end of the day. I also volunteer here when I get the chance. I assisted in a very small way with the cosmetic restoration on the Hunslet that served on the Western Front before it came down under and slaved away on the sugar cane lines in Queensland.

The DD17 tank loco progresses with its new all welded steel boiler.

The DD17 tank loco progresses with its new all welded steel boiler.

C17 #974 and the BB181/4 1079 and 1089 (Which is Australia's Evening Star). I hope to have some time firing on the #974 when it goes into service at the Maryvalley Rattler, fingers crossed.

C17 #974 and the BB181/4 1079 and 1089 (Which is Australia's Evening Star). I hope to have some time firing on the #974 when it goes into service at the Maryvalley Rattler, fingers crossed.

One of the 2000 class railmotors.

One of the 2000 class railmotors.

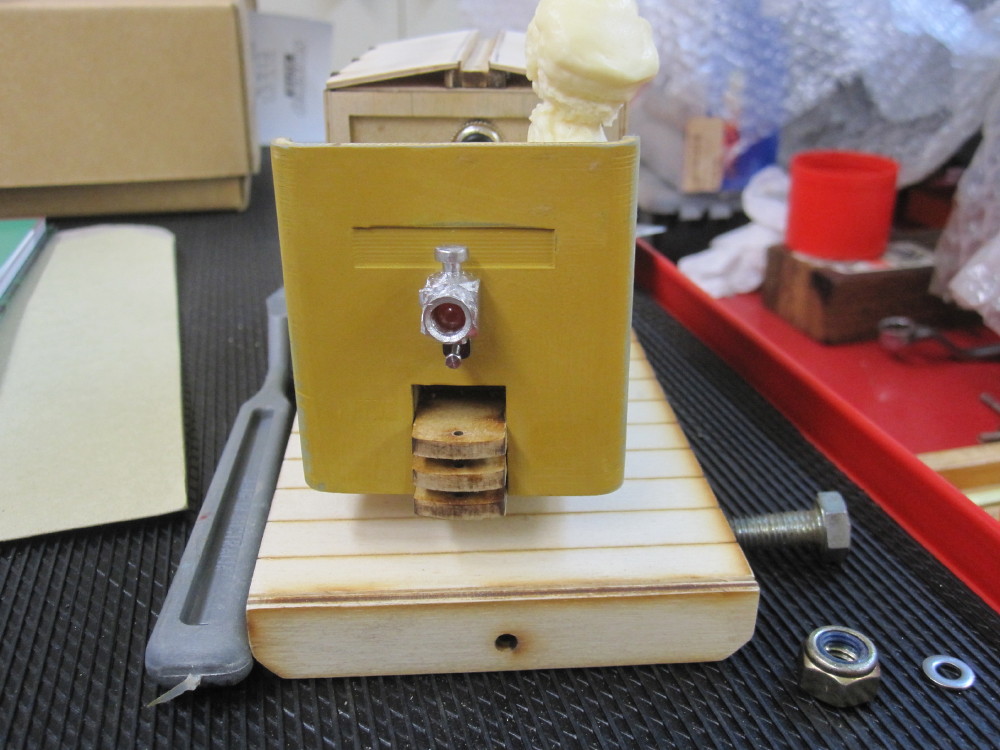

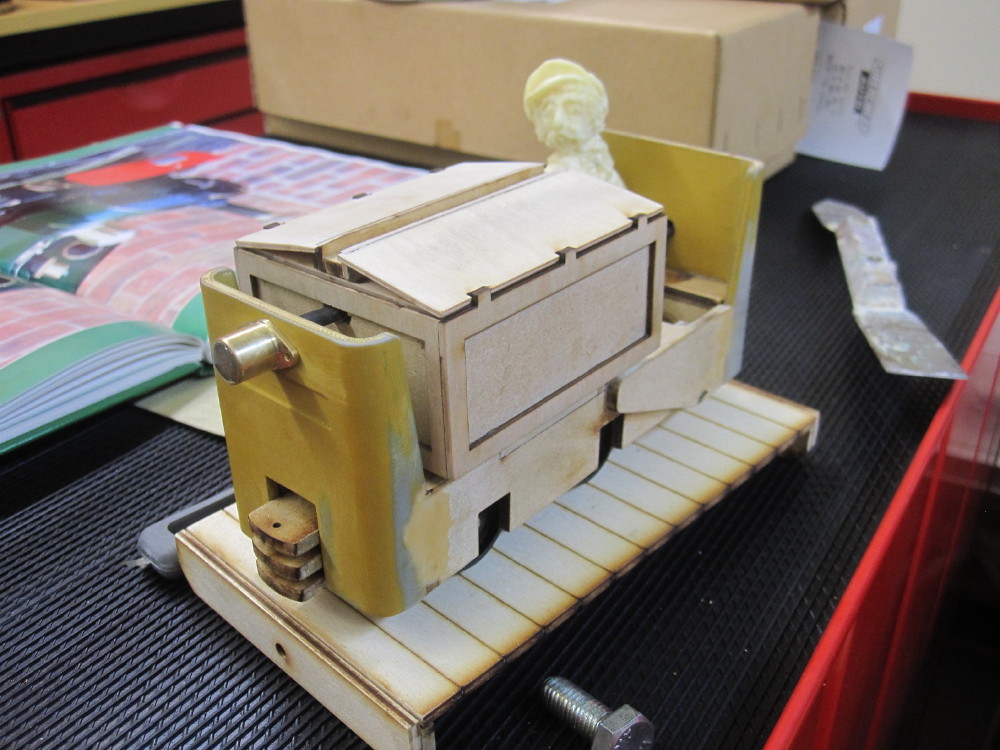

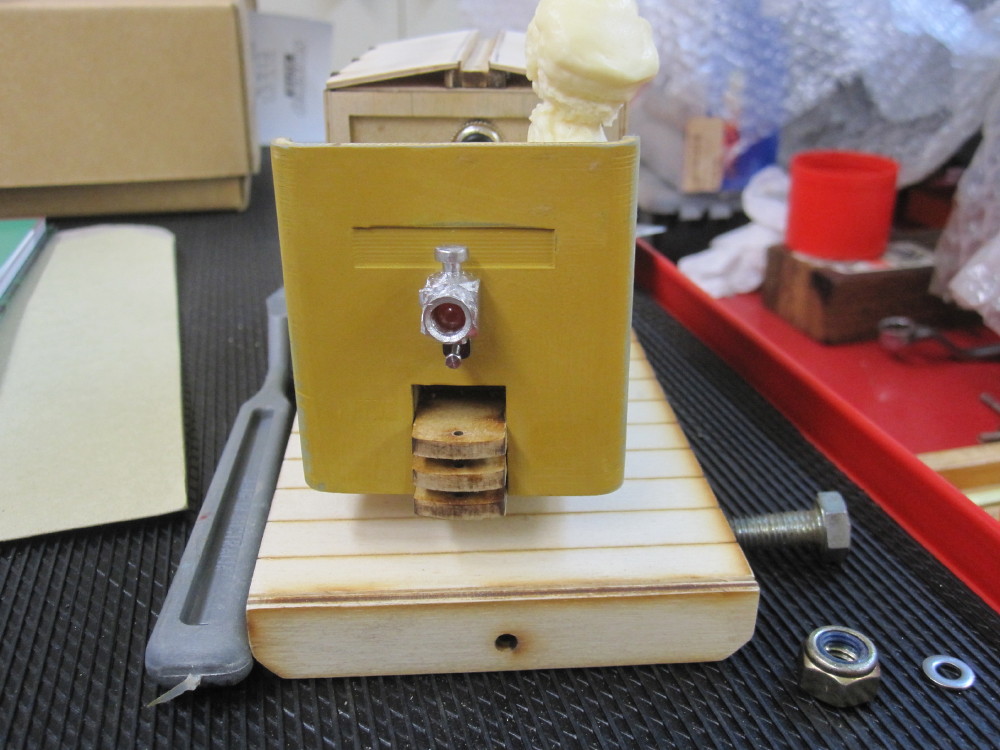

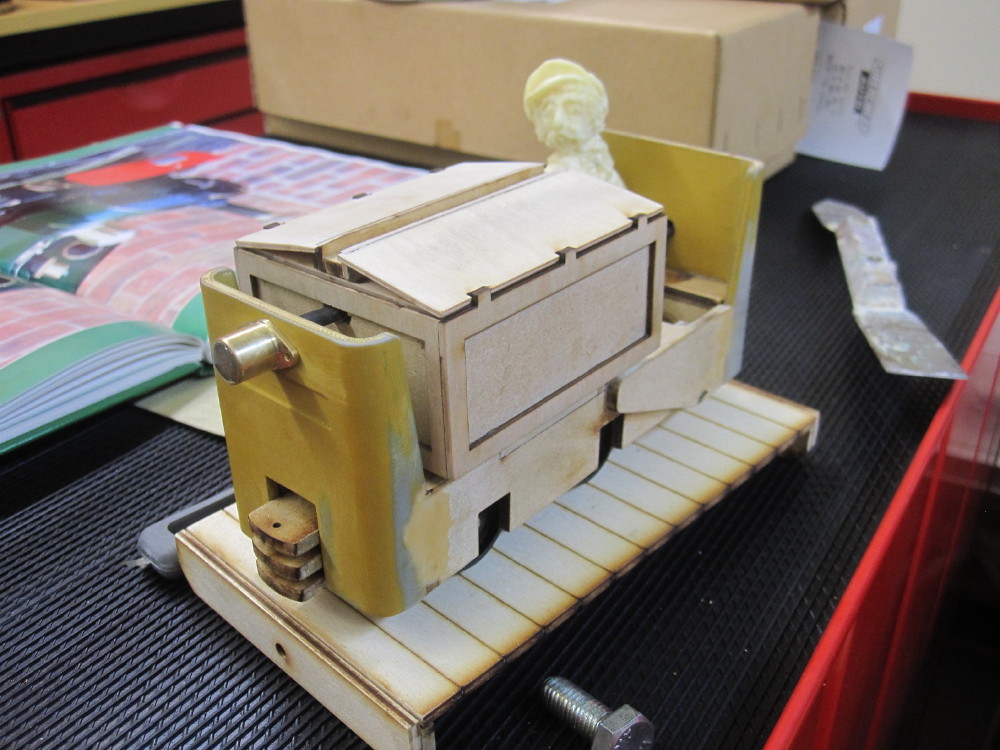

Home on Saturday night after a good and eventful day out, I show MAM the head light I made for the little Greenblat loco kit she got me for Christmas and later while consuming home made Fish and Chips (Salmon = yum) and a glass or two of Red, MAM comments "where is the tail light, you are making a taillight for it !" "Aghhhhhhhhhhhhhh, yes, yes, you are right, it has to be done" . Sunday morning I get up, cup of tea, I rummage through what I have, LEDs, wires, connectors, switches and a Pendle Valley Tail lamp kit. I ponder all of this. I am an ignoramus with electrics but for the basics. I get in a right muddle. About 6 hours later, I have some thing that works.

Home on Saturday night after a good and eventful day out, I show MAM the head light I made for the little Greenblat loco kit she got me for Christmas and later while consuming home made Fish and Chips (Salmon = yum) and a glass or two of Red, MAM comments "where is the tail light, you are making a taillight for it !" "Aghhhhhhhhhhhhhh, yes, yes, you are right, it has to be done" . Sunday morning I get up, cup of tea, I rummage through what I have, LEDs, wires, connectors, switches and a Pendle Valley Tail lamp kit. I ponder all of this. I am an ignoramus with electrics but for the basics. I get in a right muddle. About 6 hours later, I have some thing that works.

I think it needs a little awning over the cab to keep the tropical sun off Mr Starboard.

Now what has this got to do with steam locos ????

It is intended that Llewellyn Loco Works #1 will have working head light and taillight on the tender as night time running is one of the reasons to live. So all of this is a good training and education excercise in LEDs, diodes and soldering for a proper or at least a better job to be done on the steamer. (with better and smaller connectors)

The Greenblat will be painted Safety Yellow as it will the POR's PR inspection trolley for running the road etc .

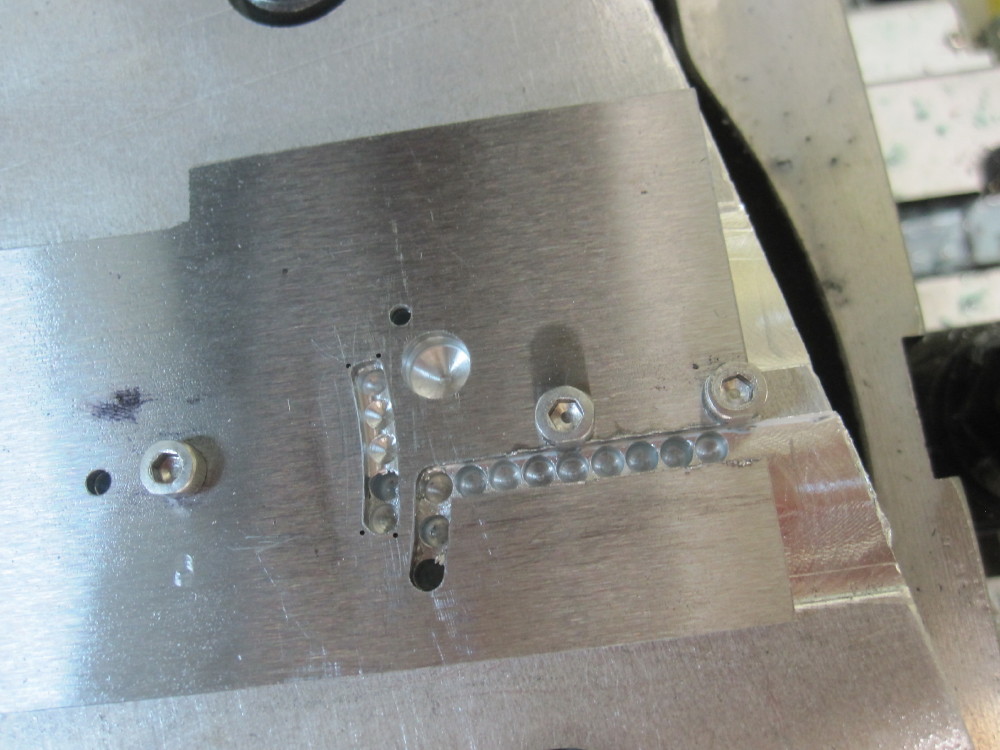

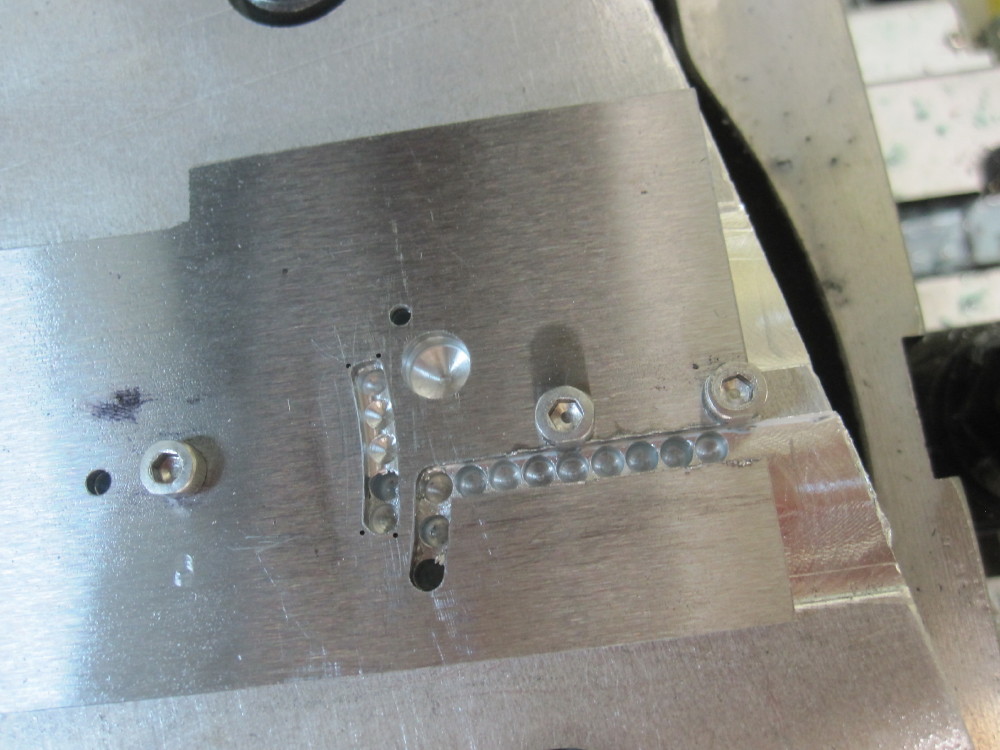

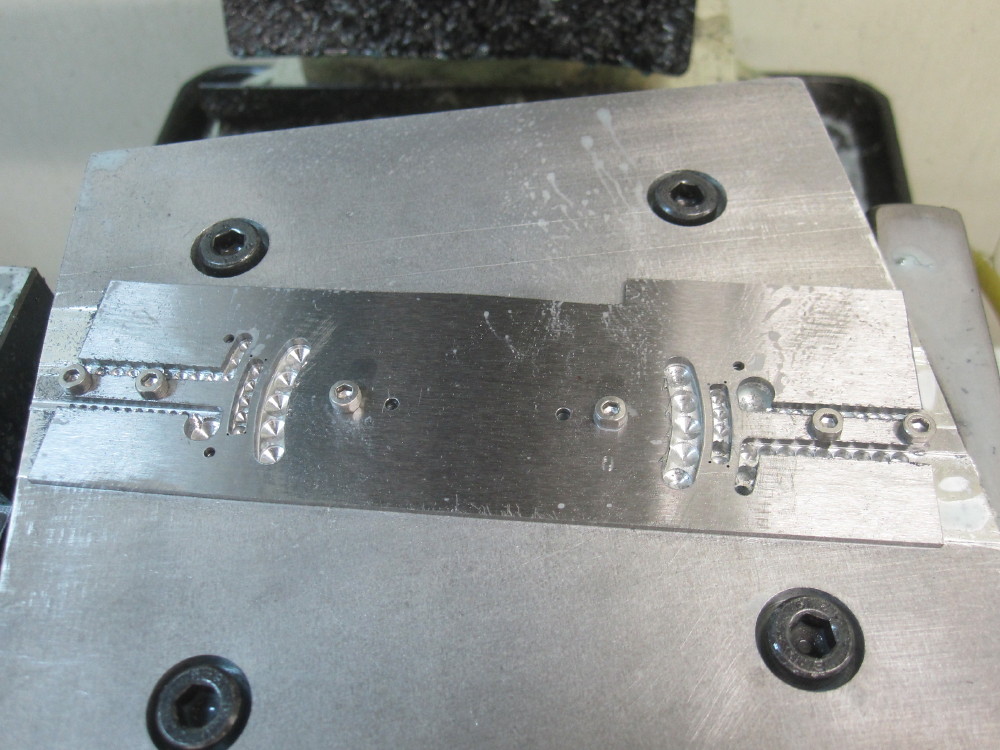

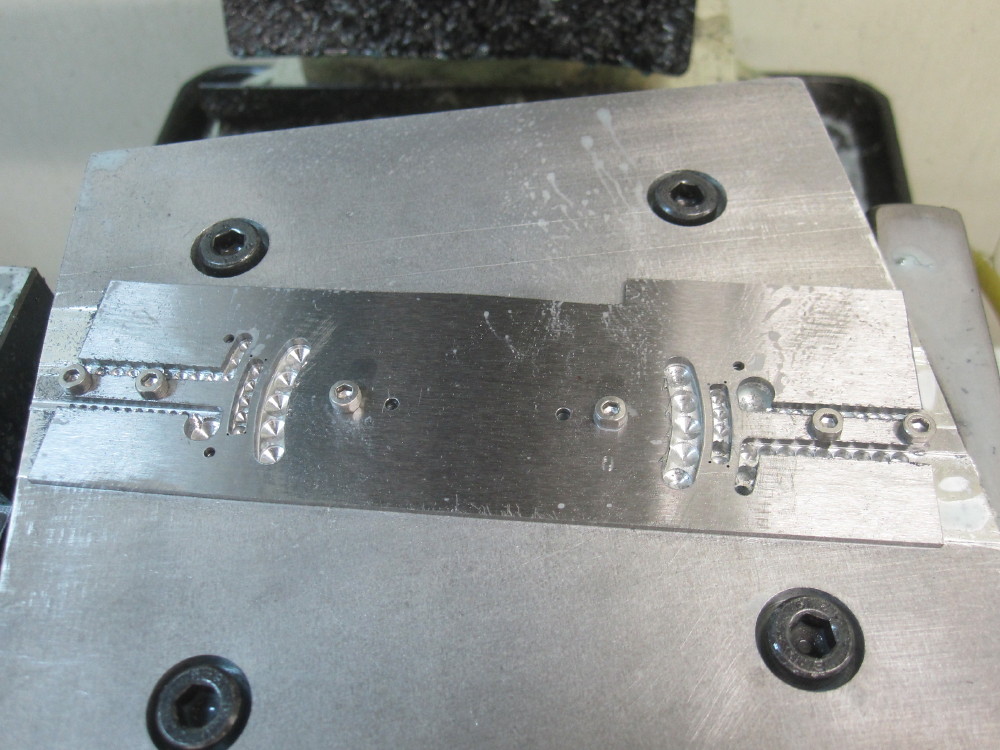

Later on Sunday Evening the expansion links are progressing while listening to the Test Cricket. The tricky milling is done. Now the next stages of cutting and fabrication begins.

While the mills was buzzing, MAM was ordering detail parts from the UK for her Lady Ann, inspired by an article in SMT mag.

While the mills was buzzing, MAM was ordering detail parts from the UK for her Lady Ann, inspired by an article in SMT mag.

Last edited by

Hydrostatic Dazza on Sun Mar 11, 2018 9:30 pm, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

-

Contact:

Post

by tom_tom_go » Sun Mar 11, 2018 9:06 pm

Thanks for the pics.

I like the look of this loco:

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Sun Mar 11, 2018 9:34 pm

your desire can be sated

soon

https://www.accucraft.uk.com/products/w ... am-4-6-0t/

tom_tom_go wrote: ↑Sun Mar 11, 2018 9:06 pm

Thanks for the pics.

I like the look of this loco:

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

daan

- Fireman

- Posts: 266

- Joined: Wed Apr 12, 2017 9:25 am

Post

by daan » Mon Mar 12, 2018 9:56 am

Great work as allways, but why do you buy a slomo? With your precision you can build one yourself easily.. I do love the spanner set! Absolutely great..

"En schöne Gruess" from an Alpine railway in Holland.

-

tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

-

Contact:

Post

by tom_tom_go » Mon Mar 12, 2018 10:08 am

Not at that price, that's Roundhouse territory...

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Mon Mar 12, 2018 8:14 pm

daan wrote: ↑Mon Mar 12, 2018 9:56 am

Great work as allways, but why do you buy a slomo? With your precision you can build one yourself easily.. I do love the spanner set! Absolutely great..

Thankyou for the compliments, much appreciated.

There is a lot in the design and making of a Slomo. The gearing ratios, the correct weight, then sourcing the gears, metal and non metal gears and pinions, sorting the bearings............ It would be a long learning process with much experimenting which would delay the day the loco steams. At the rate I am going it will be two more years and adding another 6 -12 months while I attempt to sort my own mechanism would depress me, I have yet to sort the signalling mechanisms for the POR and the lighting etc. For me it was much better to respect what Terry has sorted and created and give him a few gold coins and be on my happy way. I will add that Terry Robinson has been most helpful all along the way.Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

-

Contact:

Post

by tom_tom_go » Mon Mar 12, 2018 8:24 pm

I agree, a SSP Slomo is not simply a metal case with cogs and a flywheel thrown in. It has taken Terry years of development and expense to produce a product I would never run a live steamer in this scale without now.

-

daan

- Fireman

- Posts: 266

- Joined: Wed Apr 12, 2017 9:25 am

Post

by daan » Tue Mar 13, 2018 10:03 am

I do agree with that too, but there have been builds on the forum of cheap China toy momentum mechanisms in carriages which also work sort of likewise and those are not that hard to copy if you can work with precision and have the tools for it.

Roundhouse (p.e.) also makes great steamlocomotives and have spent a lot of time designing it, but that you can make yourself too if you have patience, tools and the skills. It's not a judgement towards the designer of the slomo that his device can be build easily by anyone on the kitchen table, it's the remark that if you are capable of building a live steamer to this grade of precision that an inertia device also is within reach..

"En schöne Gruess" from an Alpine railway in Holland.

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Tue Mar 13, 2018 9:41 pm

daan wrote: ↑Tue Mar 13, 2018 10:03 am

I do agree with that too, but there have been builds on the forum of cheap China toy momentum mechanisms in carriages which also work sort of likewise and those are not that hard to copy if you can work with precision and have the tools for it.

Roundhouse (p.e.) also makes great steamlocomotives and have spent a lot of time designing it, but that you can make yourself too if you have patience, tools and the skills. It's not a judgement towards the designer of the slomo that his device can be build easily by anyone on the kitchen table, it's the remark that if you are capable of building a live steamer to this grade of precision that an inertia device also is within reach..

I am yet to have a steam locomotive move under steam that has come from my workshop, let alone work properly.

and at this moment I have made some wrong turns on the way to the expansion links being a reality .........................Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

Keith S

- Driver

- Posts: 1626

- Joined: Thu Feb 24, 2011 11:44 pm

- Location: Canada

Post

by Keith S » Wed Mar 14, 2018 4:51 am

... and also, I for one would not blame you for saying "I simply don't feel like it".

I am sure I could make my own "chuff pipe", but I am pleased to buy one from Chris Bird.

I enjoy building my own flying model aeroplanes. Each one obviously needs a propellor, and I am more than capable of carving one from wood. However, I am not interested in doing so. Therefore, the propellor is one thing I choose to purchase, even for a "scratch built" model.

You needn't justify your decision with anything more than "I simply didn't feel like it". You're right, Terry deserves the business. If you feel like giving him your business, that's your business.

-

ge_rik

- Administrator

- Posts: 6545

- Joined: Sun Oct 25, 2009 10:20 pm

- Location: Cheshire

-

Contact:

Post

by ge_rik » Wed Mar 14, 2018 7:28 am

Just been catching up with this thread. As always, in awe of your engineering skills. Really great to see raw lumps of metal being transformed into exquisite miniature components. It does make me appreciate why commercial live steam locos are the price they are, though no doubt they use CNC for quite a few of their processes.

Very gratifying to see that one of my humble scribblings on t'net has contributed in a minor way to the development of this marvellous machine.

Rik

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Wed Mar 14, 2018 9:17 pm

ge_rik wrote: ↑Wed Mar 14, 2018 7:28 am

Just been catching up with this thread. As always, in awe of your engineering skills. Really great to see raw lumps of metal being transformed into exquisite miniature components. It does make me appreciate why commercial live steam locos are the price they are, though no doubt they use CNC for quite a few of their processes.

Very gratifying to see that one of my humble scribblings on t'net has contributed in a minor way to the development of this marvellous machine.

Rik

Yes, your "humble scribbings" are most useful.

I am in awe how the Roundhouse mob and others make locos for what is in reality a very reasonable price, considering what it takes to buy machinery (CNC etc), maintain it and pay staff who need holidays and sick days and Superannuation etc. I am sure the owners are not down at the BMW show room every second year ordering the new model. However they have to be profitable to cover for when a CNC machine craps itself, or sales go slow, and then there is design time and development of new product so as to stay relevant in the market.

The costs of business today is crippling. From internet costs to PC and then to the workshop tooling and machinery. Insurances, public liability, let alone the materials and marketing. The time sink that is marketing today in my caper is cruel. I am self employed and the easy days of my caper was the 80's and 90's. We did not how good it was then. Digital disruption is some one else's profit margin. In this age when anything now is washed away by another 24 hours of social media, blogs, websites, twitter ................... the independent manufacturer's message is like a fart in a cyclone. Only a few hear and it is forgotten in seconds. The corporations can smash the marketing world. There is a huge tonnage of new product entering the cycling world every year and the punters who spend half their working day on the internet while the boss is not watching expect us to be able to quote the first name and weight of the ceramic ball bearing in the new (insert brand here) wheel set, and every year. After 40 years I am tired of it all. Highly commoditised .......... I would like to sit down at a pub and hear the story from the inside from the creators of Roundhouse over some fine English Ales. The toil they have endured to stay relevant. I can appreciate this. In my caper, I have to remind many that making bikes is not my hobby, it is my chosen path of professional expression. I want to knock off work and get to the Red Room or go camping ! I worked over 10 hours yesterday, and after a lovely meal last night it was hard to get to the Red Room and paint another coat of yellow on the sample signal kit, then start the mill to make another replacement part for the expansion link. I don't know how I did it but I thinned some material to 1.20mm rather than 1.60mm so I have to prepare another piece. These expansion links have been the least favourite part of my loco build so far. Toil, persevere at the toil, toil on. End of first world winge from down under.Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

-

Contact:

Post

by tom_tom_go » Wed Mar 14, 2018 10:13 pm

Take a break from it if it's becoming a 'job' to build the loco.

Hobbies are meant to be picked up when time and enthusiasm allows.

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Wed Mar 14, 2018 10:15 pm

To quell the rumours, I have no intention to produce kits or sell locos. I have no desire to sell drawings or any such like, I will share the drawings when they are proven. I want to enjoy my hobby of Model Engineering, get the Potters Orchid Railway operating and move onto the 5 " gauge locos and perhaps a 16mm Burma Railways # 9 . I may have a couple of left over castings from this project that I want to flog off when the time comes to move onto another project, but that is all.

Last edited by

Hydrostatic Dazza on Wed Mar 14, 2018 10:28 pm, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Wed Mar 14, 2018 10:27 pm

tom_tom_go wrote: ↑Wed Mar 14, 2018 10:13 pm

Take a break from it if it's becoming a 'job' to build the loco.

Hobbies are meant to be picked up when time and enthusiasm allows.

I hear you, I appreciate your comment, however I do like my time in the Red Room in the evenings.The links are in my mind are to be over come, it is like climbing a mountain, hard yakka, get to the top, make camp and boil the billy, sip the tea and enjoy a feed while looking at the view, another week or two on the links and I might have them licked and that will feel so good. I am keen to mount them up on the brackets and see them swing. I find if I do some painting or a wee bit of time on the kits or signals is a good thing. If there is still daylight I will prime the battery loco and flat top wagon. That eases me into the machine work. See you all in 2020 (2019 I think is too optimistic) .

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Sat Mar 17, 2018 8:54 pm

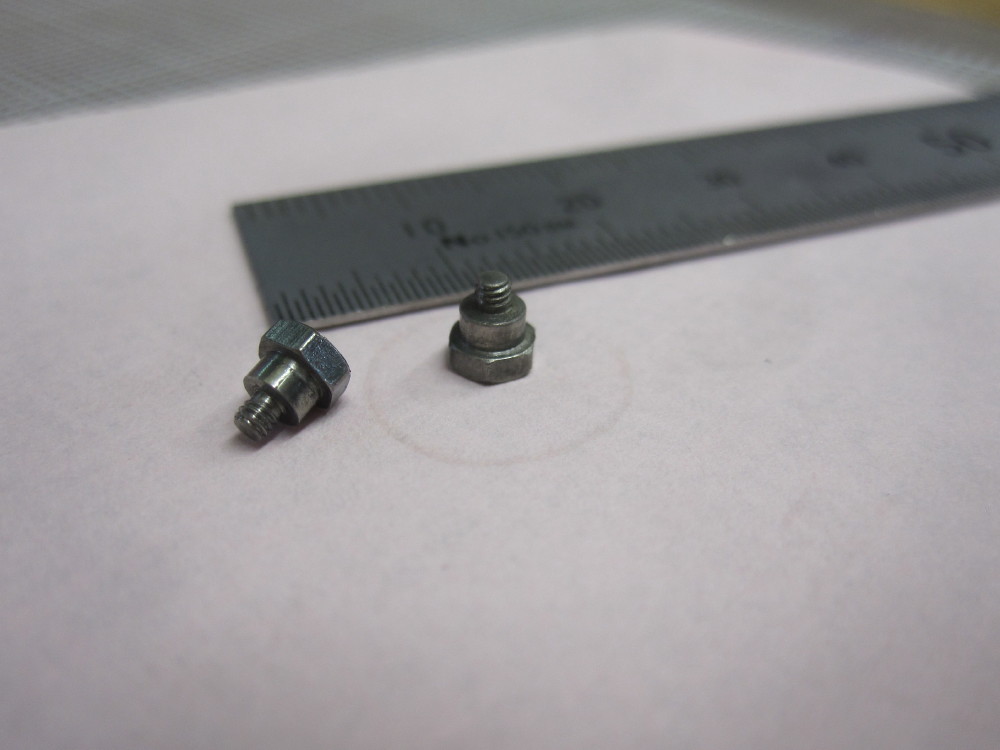

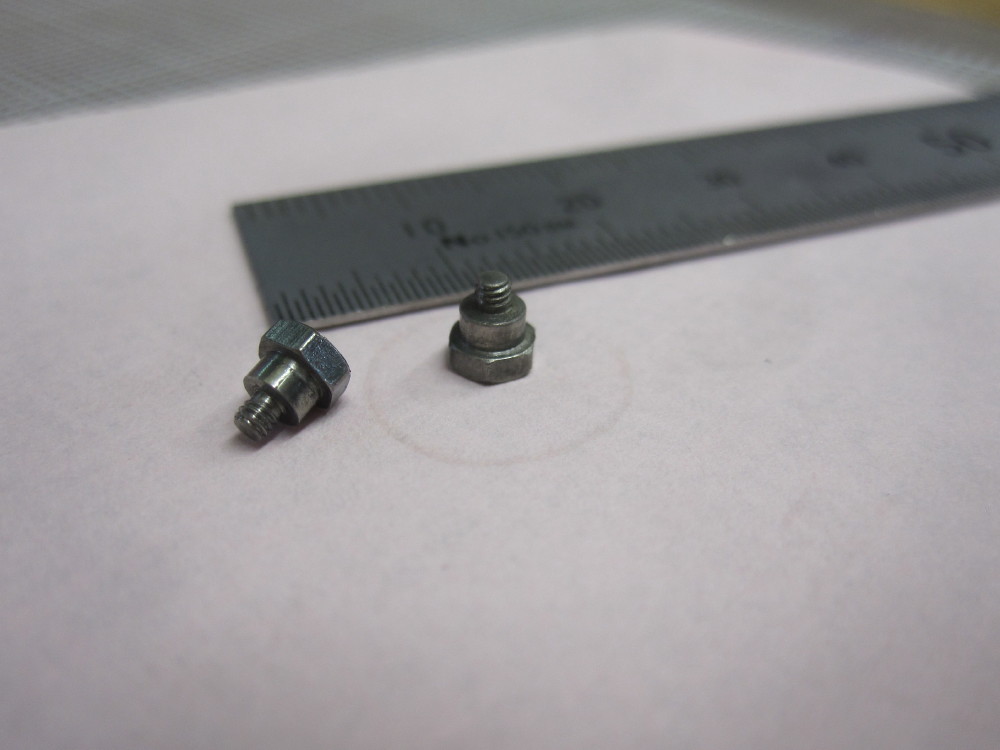

4mm Hex meets Myford to be come die block pins, I case hardened them with "Cherry Red". That was my Saturday arvo.

There will be the critics who will say, wear the pin not the link, but the pins contact the link with a round surface, unlike bigger scale die blocks, which have a surface to match the link. In my mind the curved surface will wear very quickly so hence I case hardened. In hindsight I should have gone the whole journey and made it a block with a screw through it, with milled surfaces to match the link. I suppose I still could and make it out of PB....................Pause. Next time eh.

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

-

Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

-

Contact:

Post

by Hydrostatic Dazza » Wed Mar 21, 2018 8:32 pm

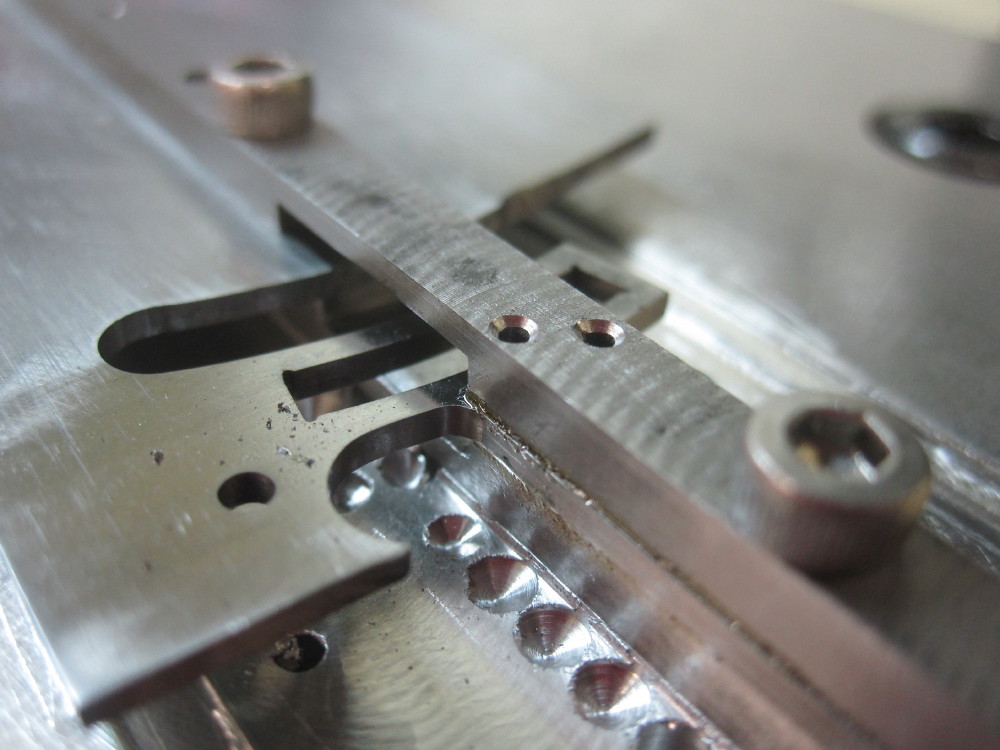

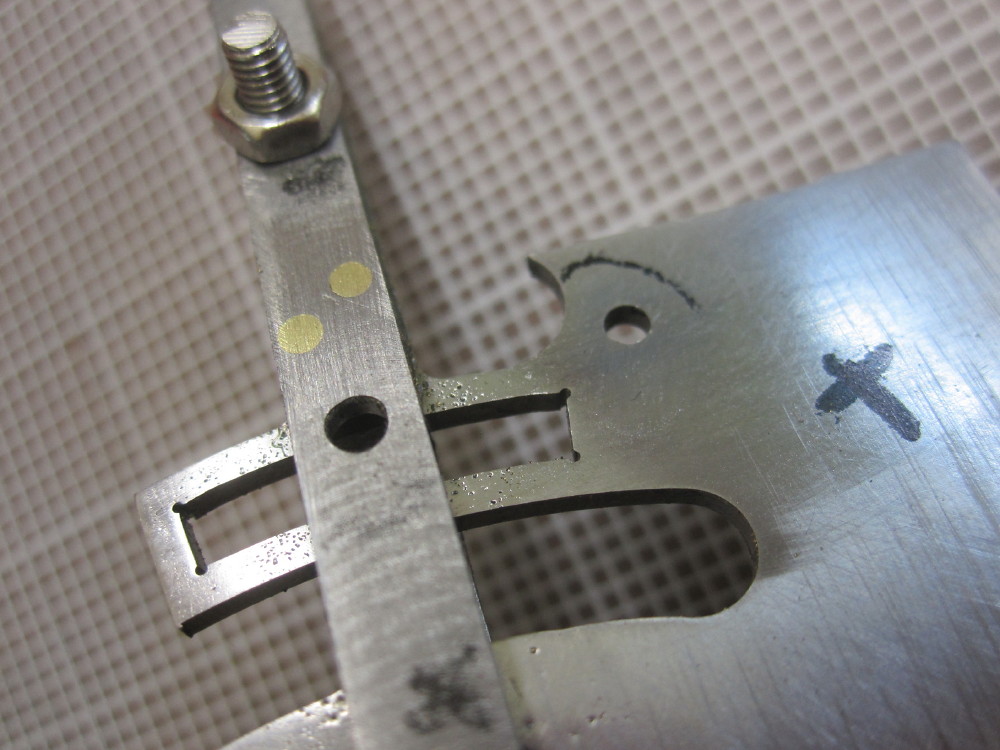

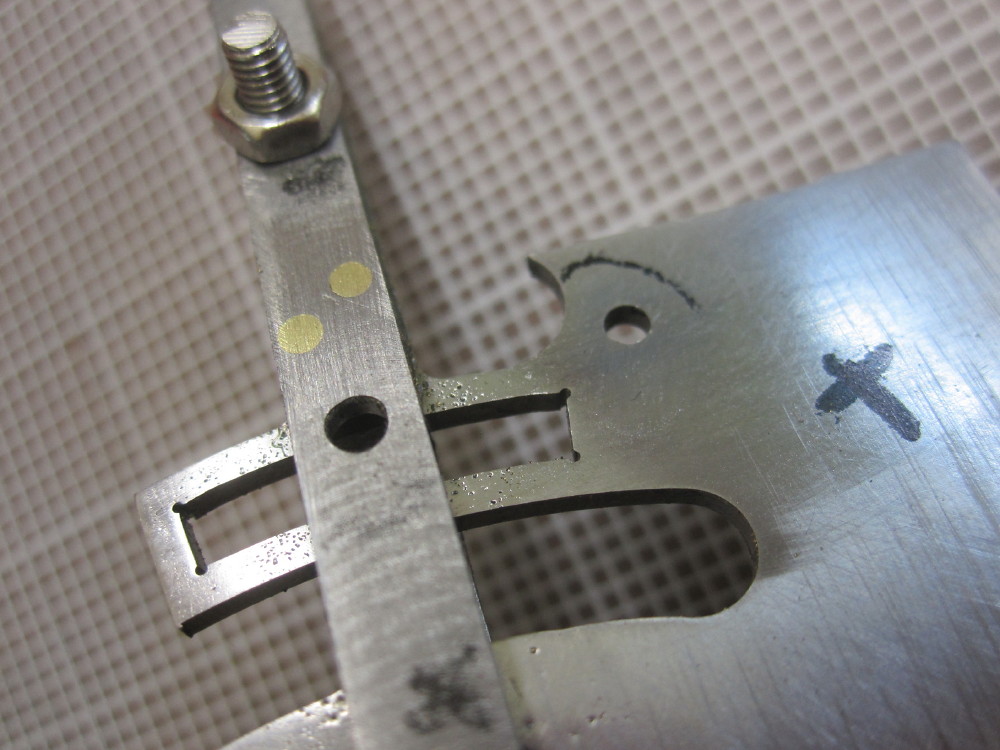

A wee bit more on the expansion links

drilled and reamed the 2.50mm trunnion pin holes and inserted 1.20mm brass round and riveted over, cleaned off the countersinks.

I am most pleased that these are nearly done. Got to go carefully to avoid ruining them with a dopey mistake or slip.

Last edited by

Hydrostatic Dazza on Thu Mar 22, 2018 10:04 pm, edited 2 times in total.

Cheers from Dazza, The Hydrostatic Lubricator  The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Who is online

Users browsing this forum: No registered users and 2 guests