I would of just bought these

Llewellyn Loco Works #1

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

For kicks and giggles, the 0.50mm carbide PCB drill did its work again. Oil holes in the con rod big end. I had missed pinning one crank to an axle so I have done that, 1.25mm silver steel pin and it is put aside for the Loctite to cure and then I can assemble the rods etc and check piston end clearance.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Re: Llewellyn Loco Works #1

The first post on the rods was on 14th of January. This one is the 27th of January. So almost 2 weeks of work on 2 magnificent driverods.. Where do you get such patience?

"En schöne Gruess" from an Alpine railway in Holland.

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Thanks. I am self employed and I have to work to earn a crust of bread, so it is some evenings for an hour or two. I am not urging to have it done, a rush to have it running, but then being a bit let down by some of my perceived short comings. I am also terribly terribly slow. I measure three times, making a cut and repeat.........................make a cup of tea..............................make another cup of tea................. I am also working on the cab drawings now and soon the tender. Also how to fit the 5 servos in. All new stuff for me this RC gear. Last night I was checking and creating /printing off 2 D drawings for the anchor link and combination lever and associated pins. I also update and edit the 3D and 2D drawings after each part, so who ever might use these drawings in the days to come will curse me a little bit less than normal.

MAM and I are off soon this Sunday morning to collect rocks, to start a stock pile of terra forming materials for the Potters Orchid Railway.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Peter Butler

- Driver

- Posts: 5243

- Joined: Sun Sep 09, 2012 10:33 pm

- Location: West Wales

Re: Llewellyn Loco Works #1

I hear there is a big red rock over your way, that might look nice in your garden and I doubt they would miss a sack or two!Hydrostatic Dazza wrote: ↑Sat Jan 27, 2018 8:02 pmMAM and I are off soon this Sunday morning to collect rocks, to start a stock pile of terra forming materials for the Potters Orchid Railway. [/color][/b] [/color][/b]

The best things in life are free.... so why am I doing this?

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

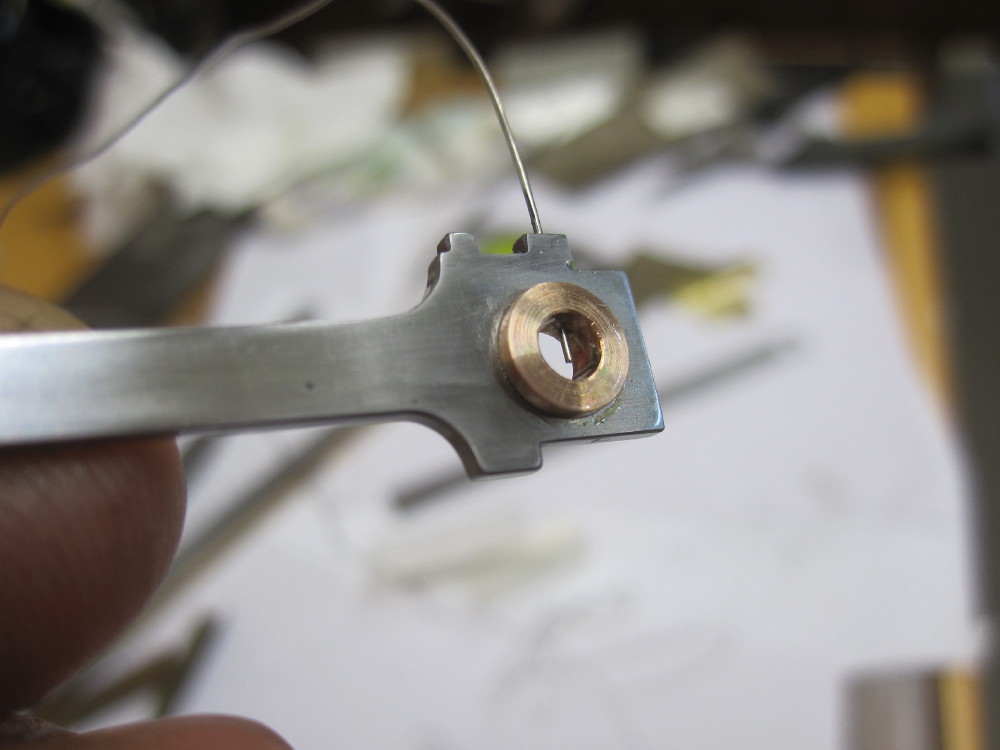

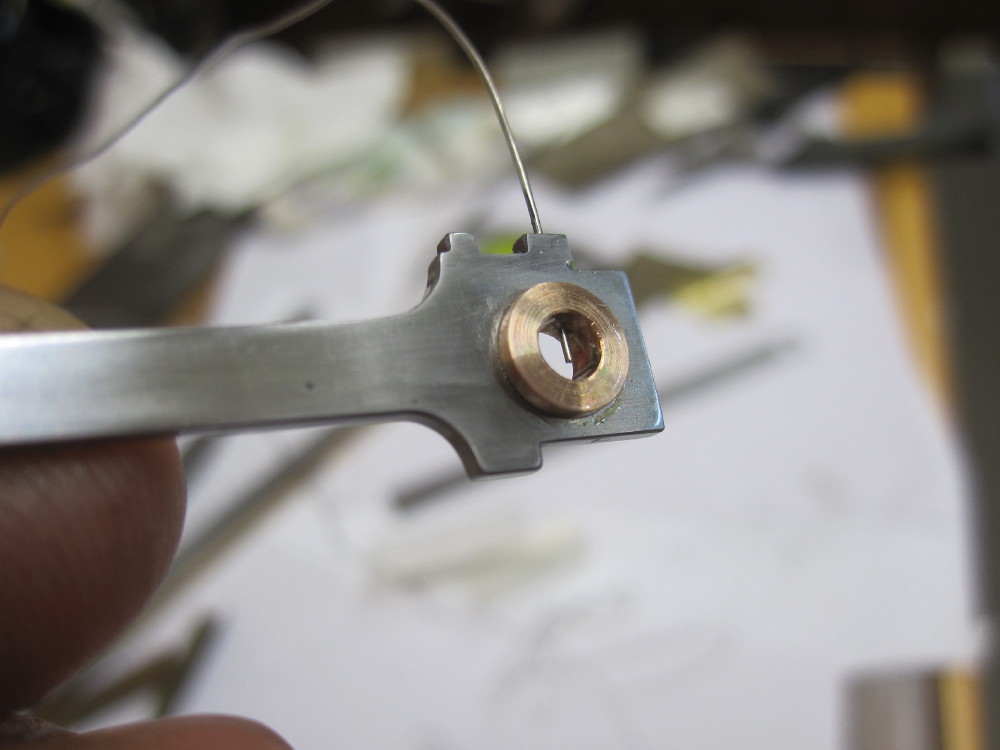

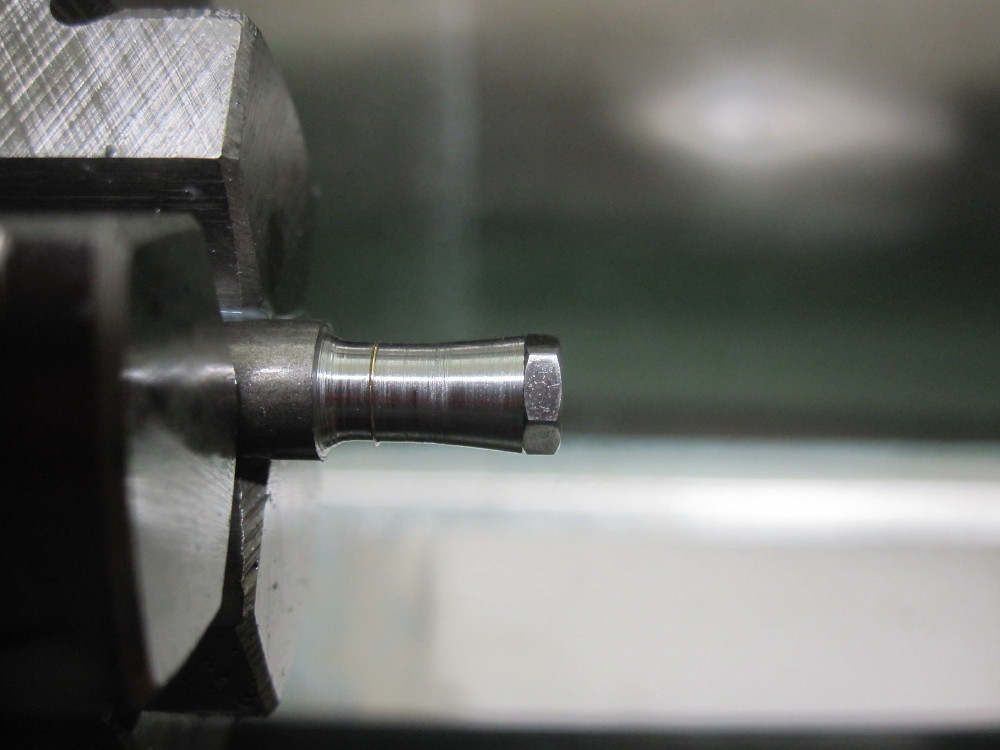

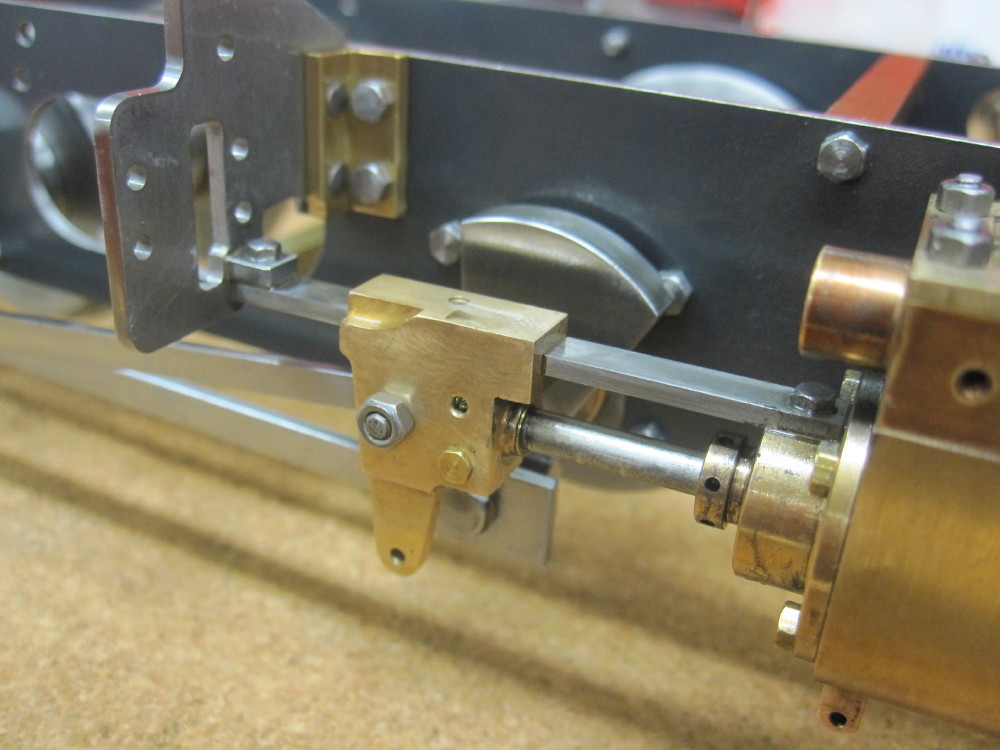

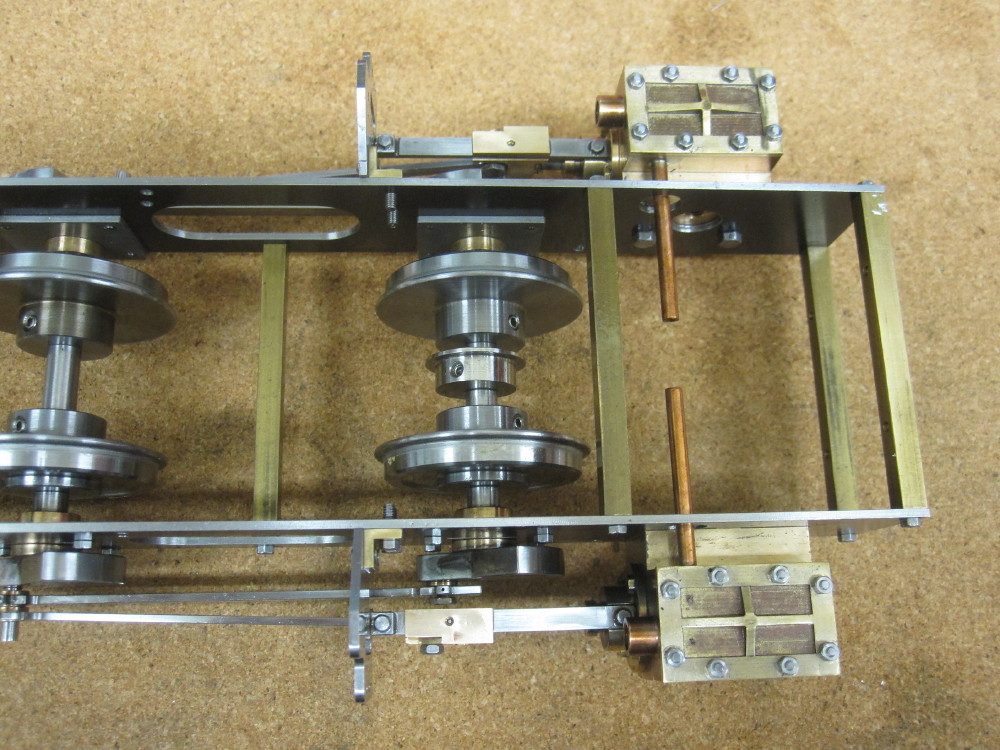

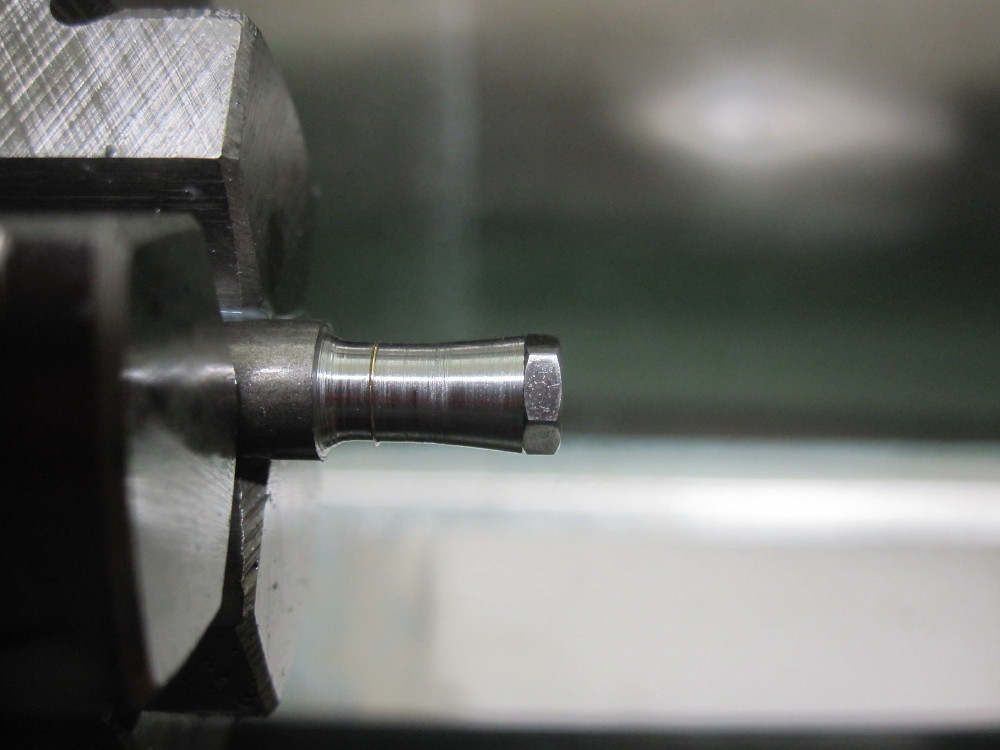

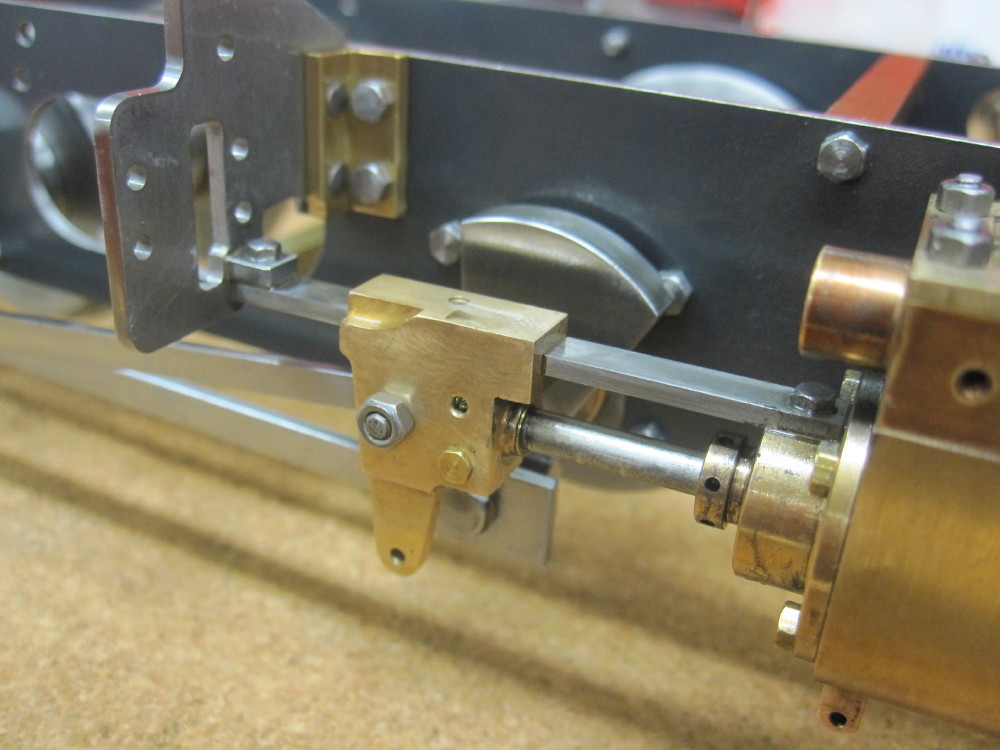

I checked the end clearances in the cylinders and it was close, but to fiddle it and to snug up the piston rod so it was up against the crosshead so any possibility of slippage (grub screw grip ) is removed I made up some thin washers with 2.5mm ID and 4.5mm OD. Made the punch and then clamped them up and turned the OD to 4.5mm.

Then fitted the little fellas and the piston end clearances was within .03mm of design intent. If one is measuring and making to tolerances then there will be a small amount of lost motion in the valve gear and motion as unlike CAD which is absolute there is some lost movement in the actual loco as there is all the small amounts of bearing clearances taken up when all is moving, so the end result at the valve and piston is a bit less then design. Just like full size, as the wear takes place this lost motion increases.

All goes around as nice as expected.

Annealing what will be the combination levers

A chap at the 16mm mob asked me where are the corks

so

Then fitted the little fellas and the piston end clearances was within .03mm of design intent. If one is measuring and making to tolerances then there will be a small amount of lost motion in the valve gear and motion as unlike CAD which is absolute there is some lost movement in the actual loco as there is all the small amounts of bearing clearances taken up when all is moving, so the end result at the valve and piston is a bit less then design. Just like full size, as the wear takes place this lost motion increases.

All goes around as nice as expected.

Annealing what will be the combination levers

A chap at the 16mm mob asked me where are the corks

so

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

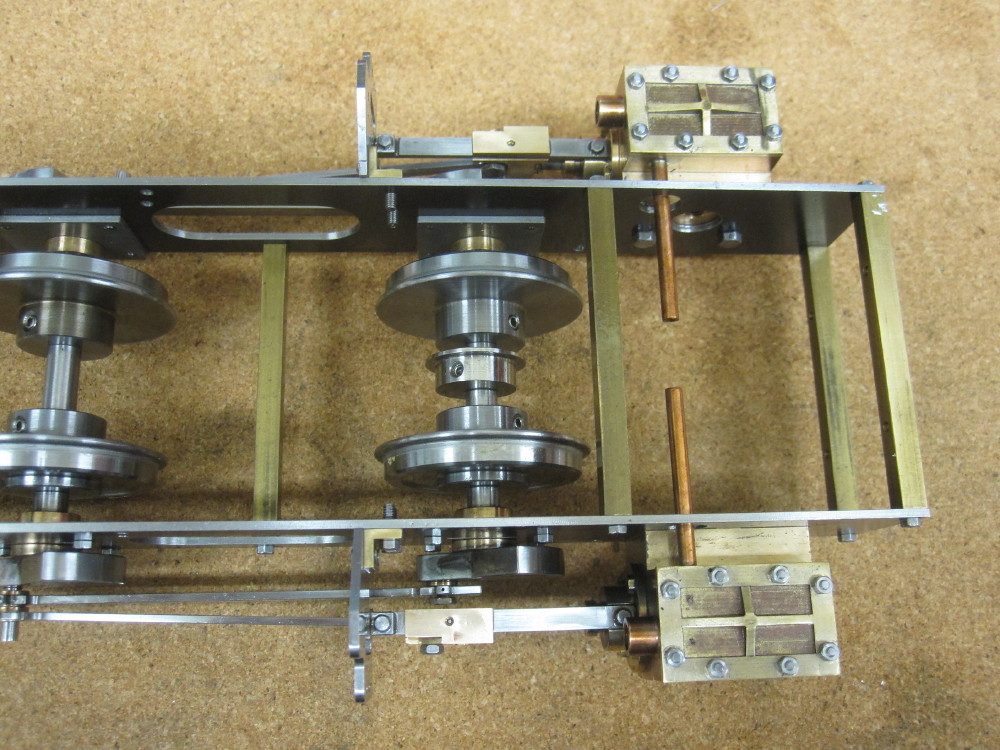

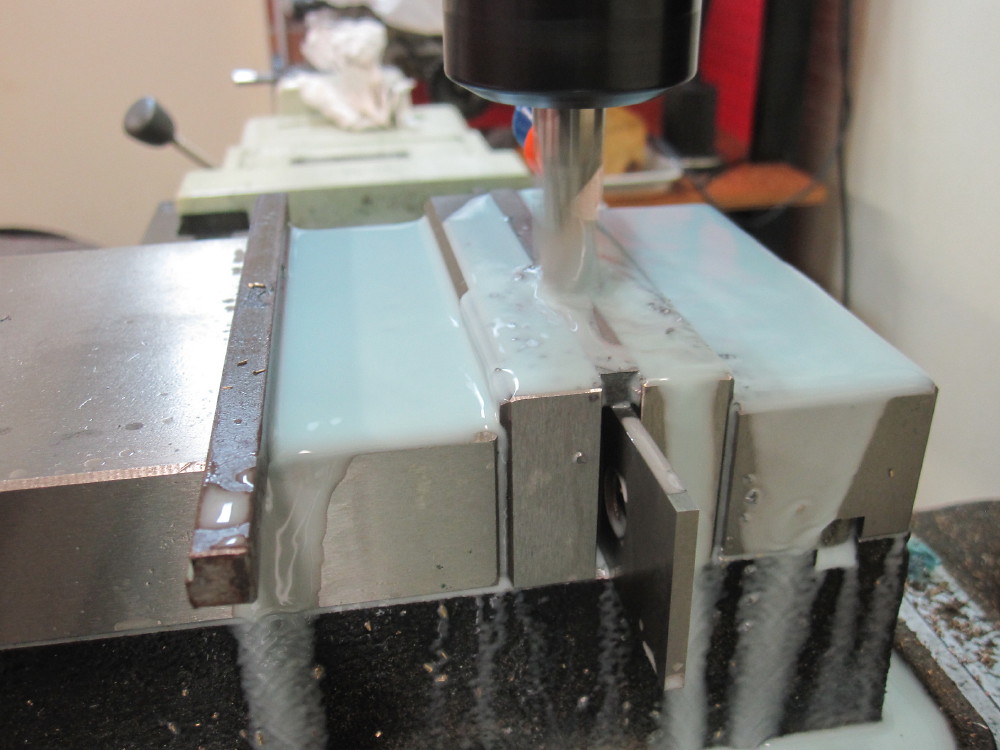

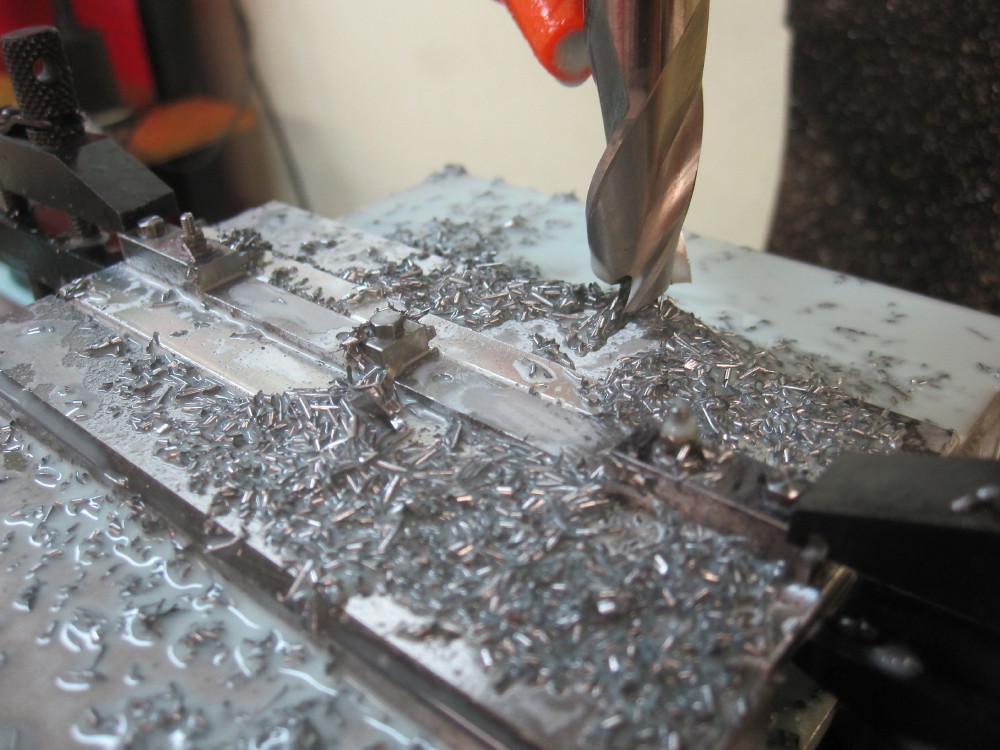

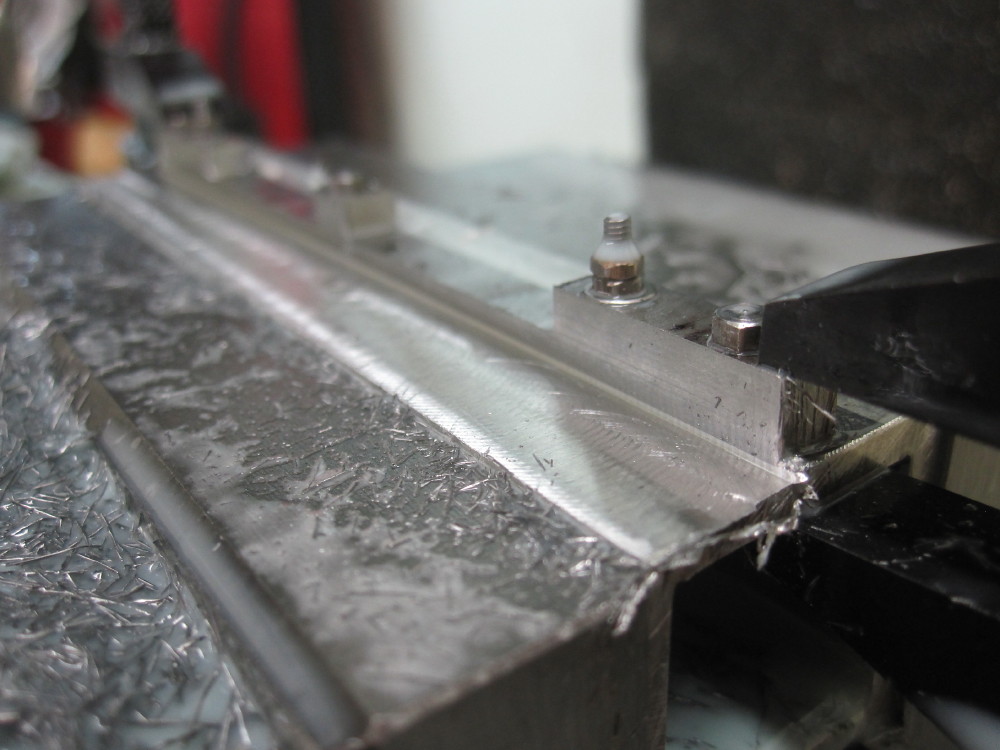

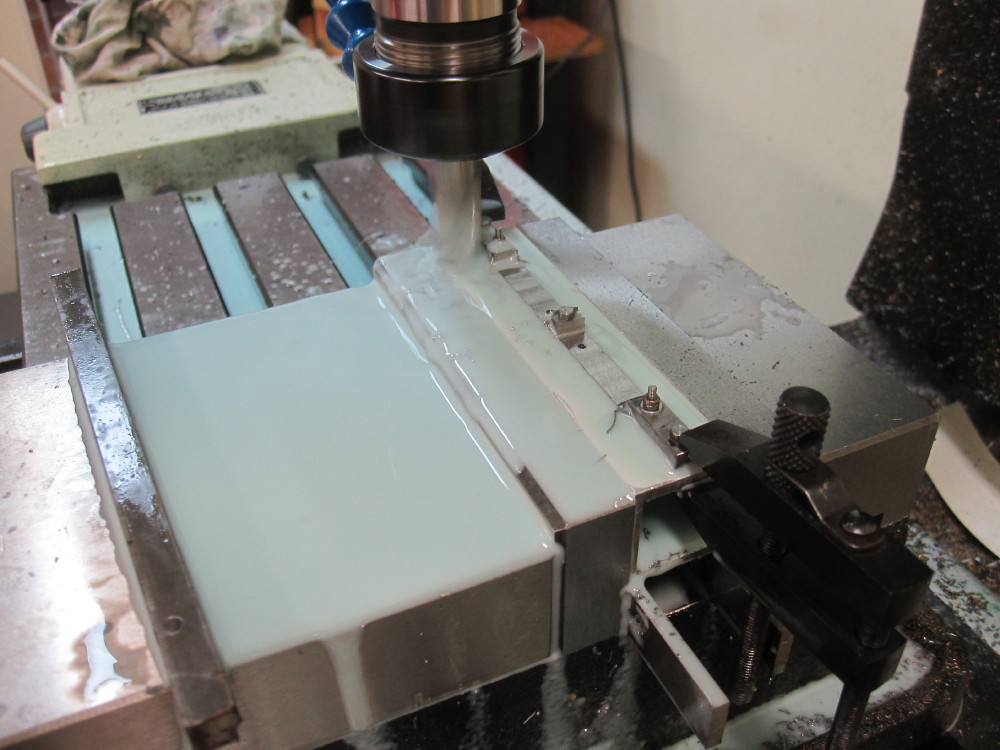

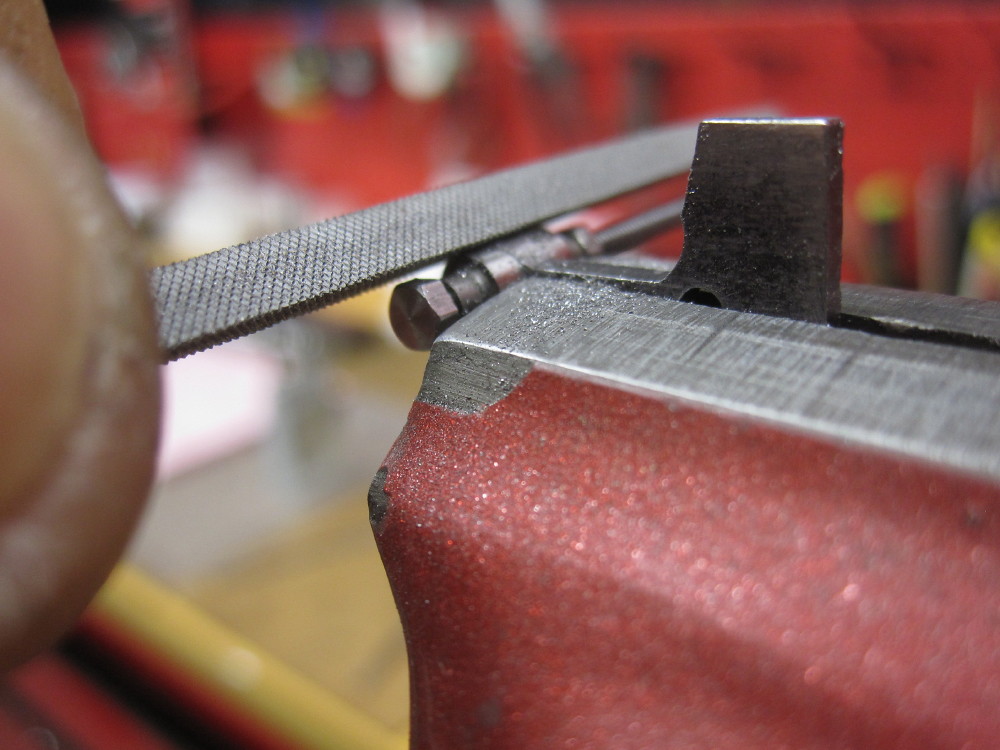

The workshop staff at the Llewellyn Locomotive works get back on to the POR O42 Tender tank contract.

They are now tackling the process of making the combination levers from a piece of annealed 1/4" Key steel that was on the shelf.

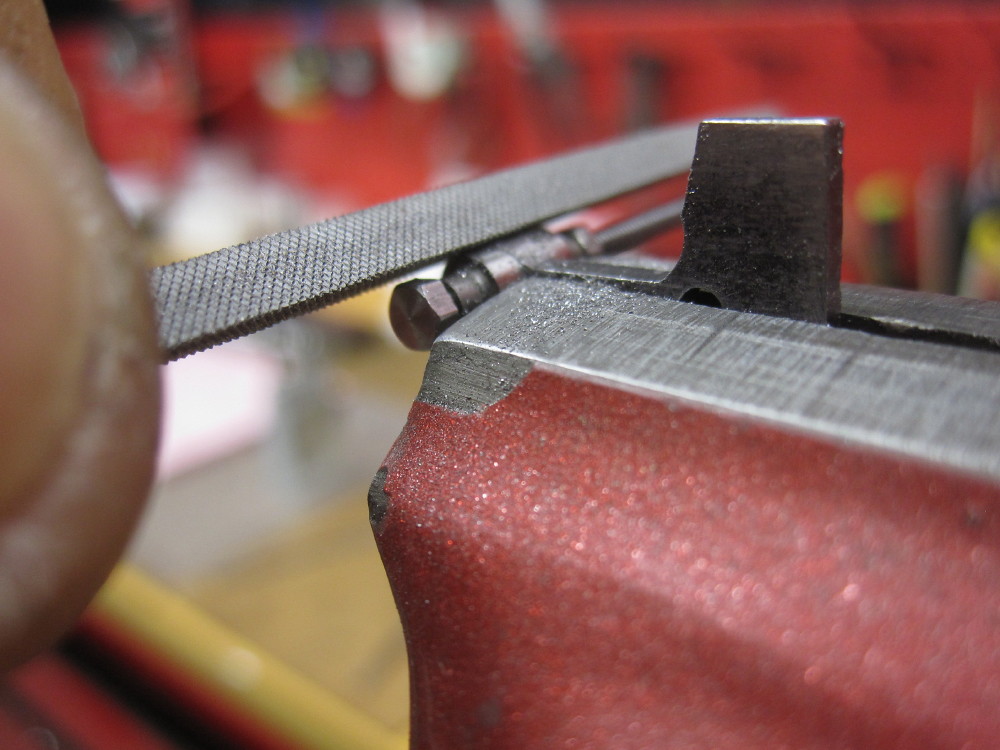

Bringing the sides down to 4.92mm

They are now tackling the process of making the combination levers from a piece of annealed 1/4" Key steel that was on the shelf.

Bringing the sides down to 4.92mm

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

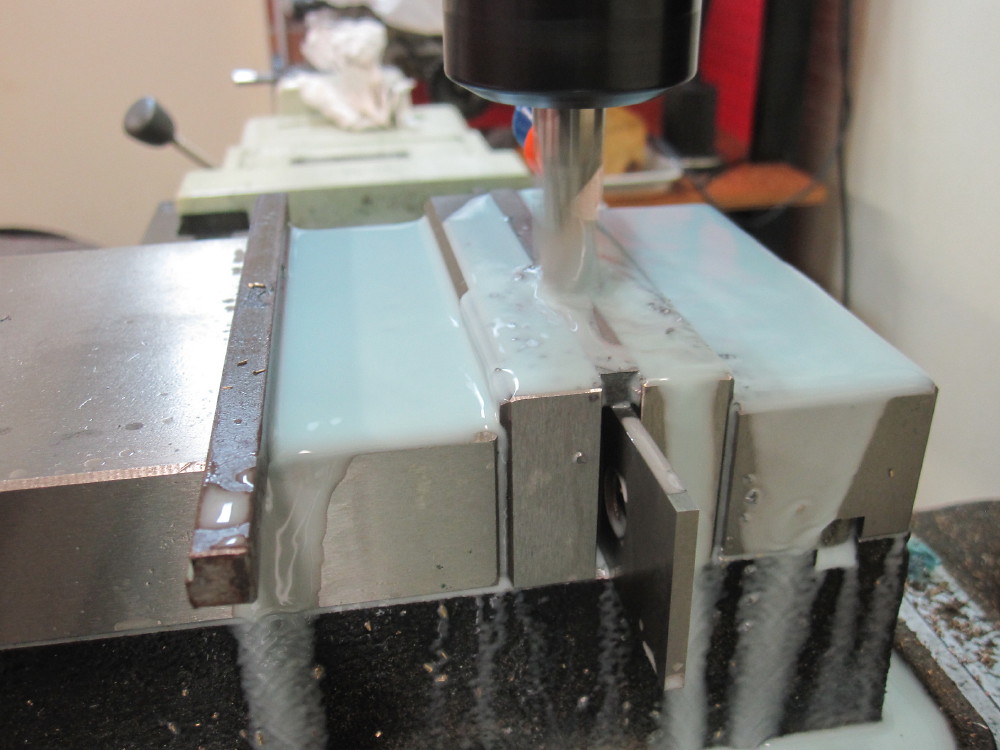

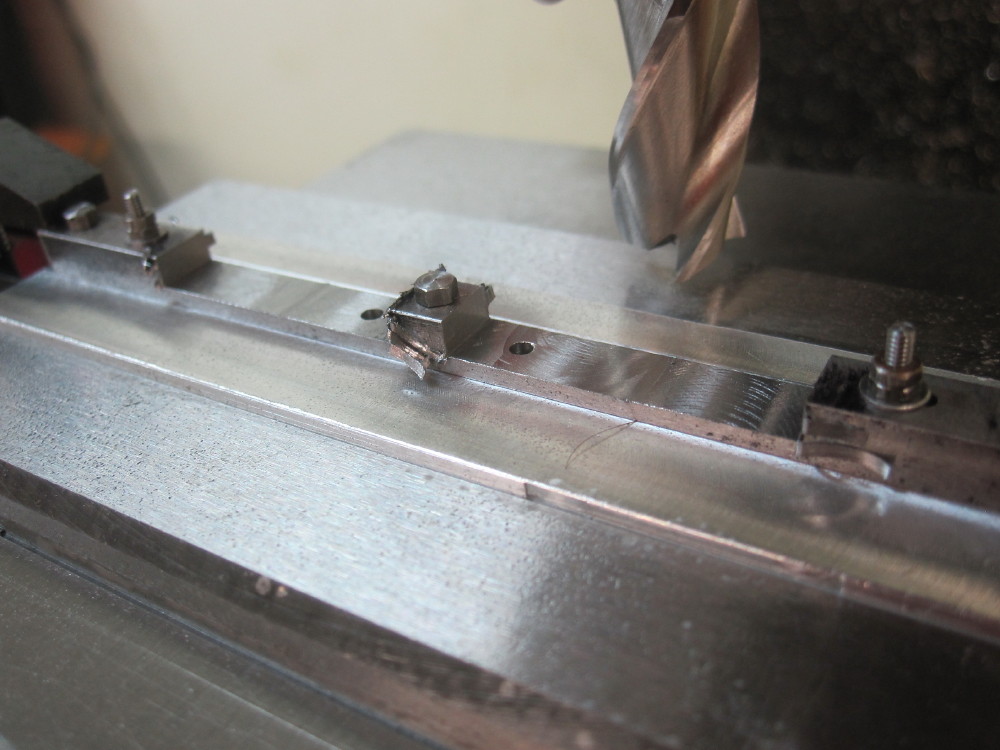

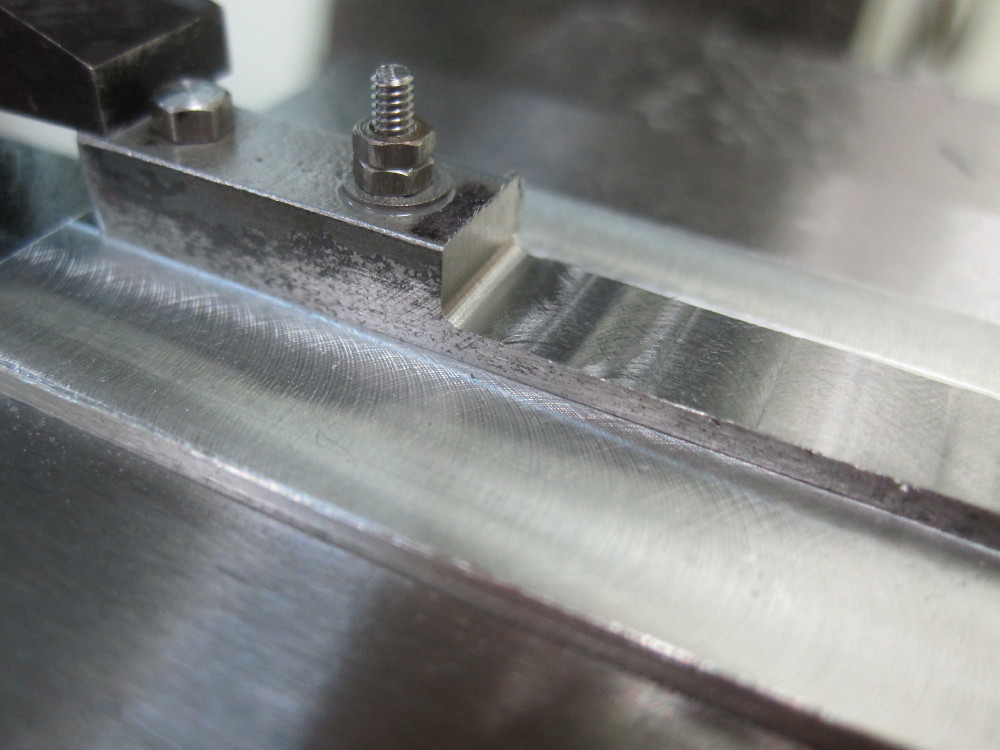

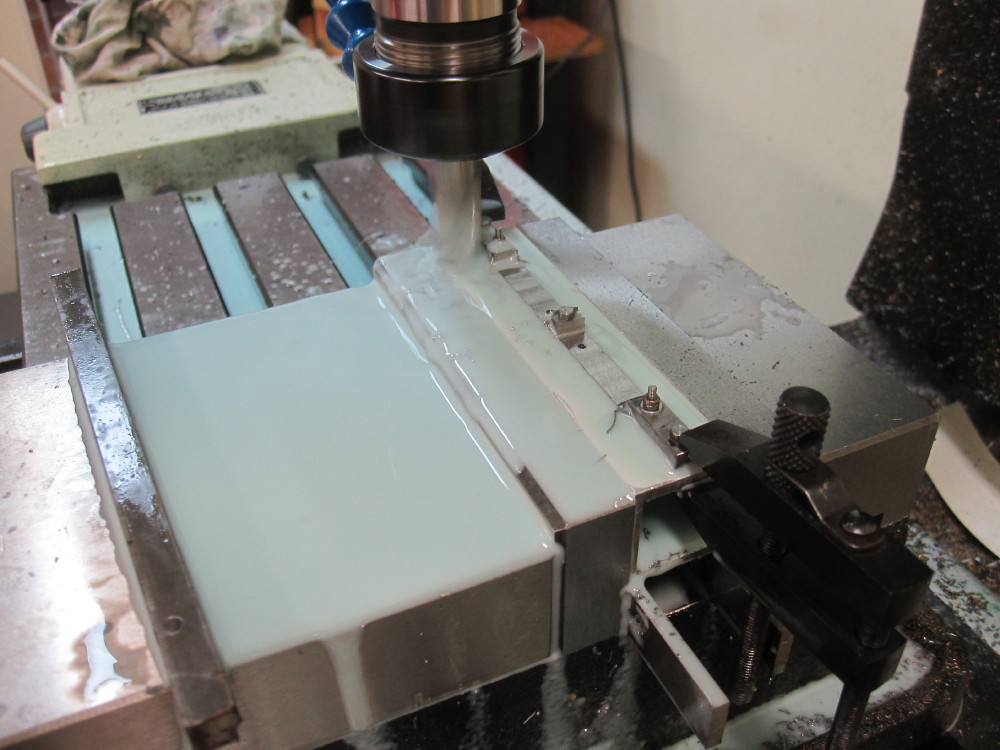

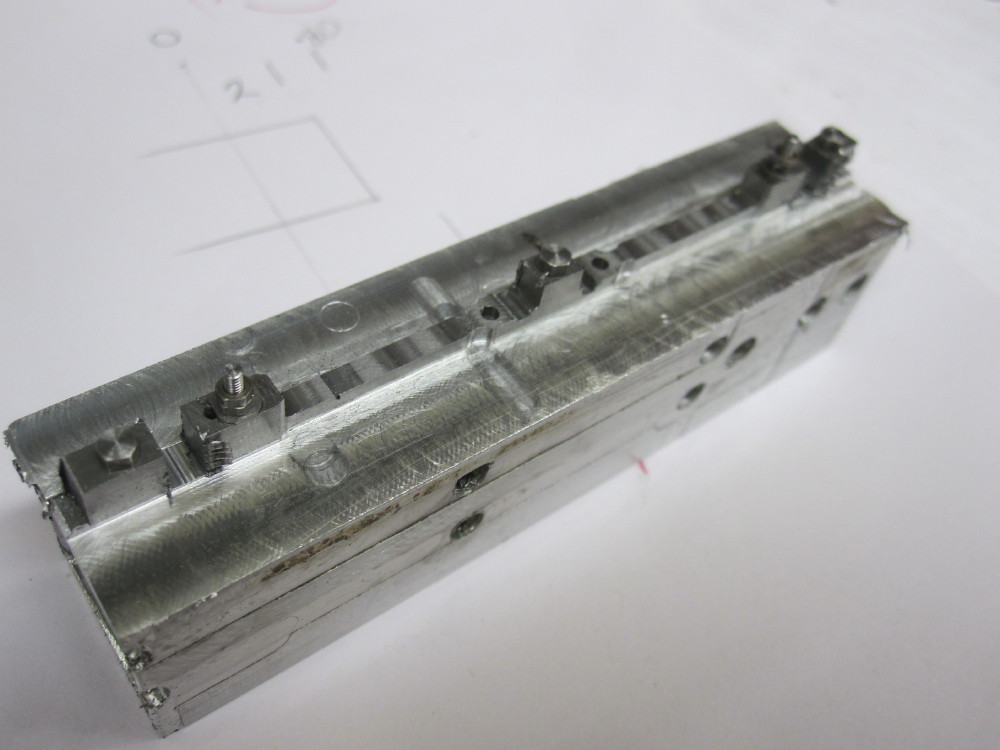

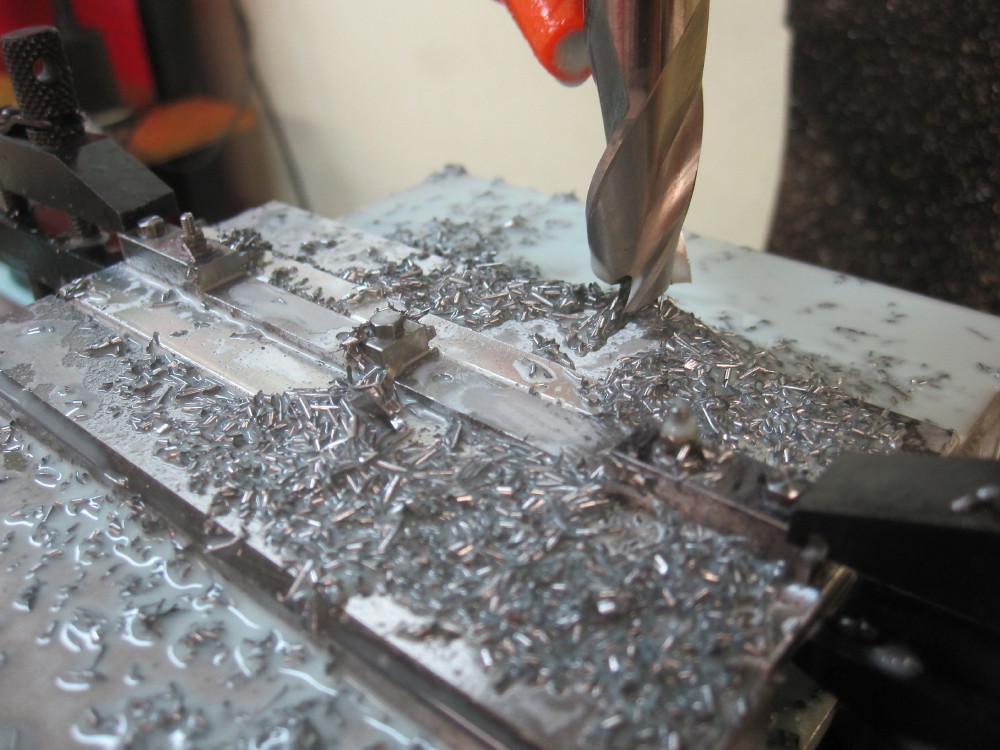

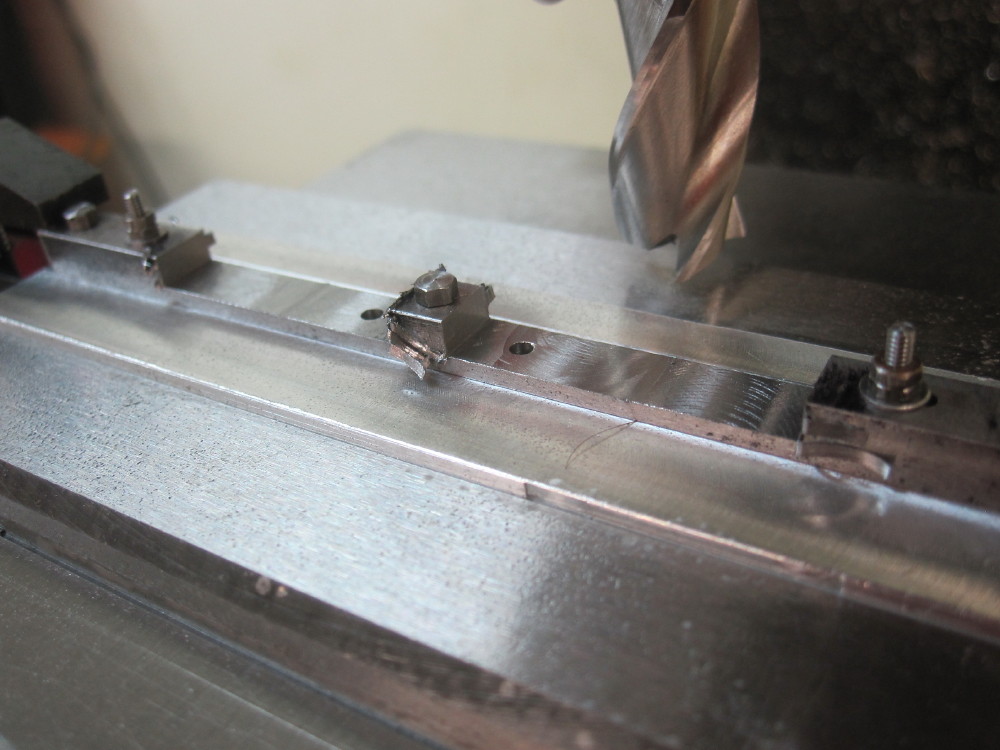

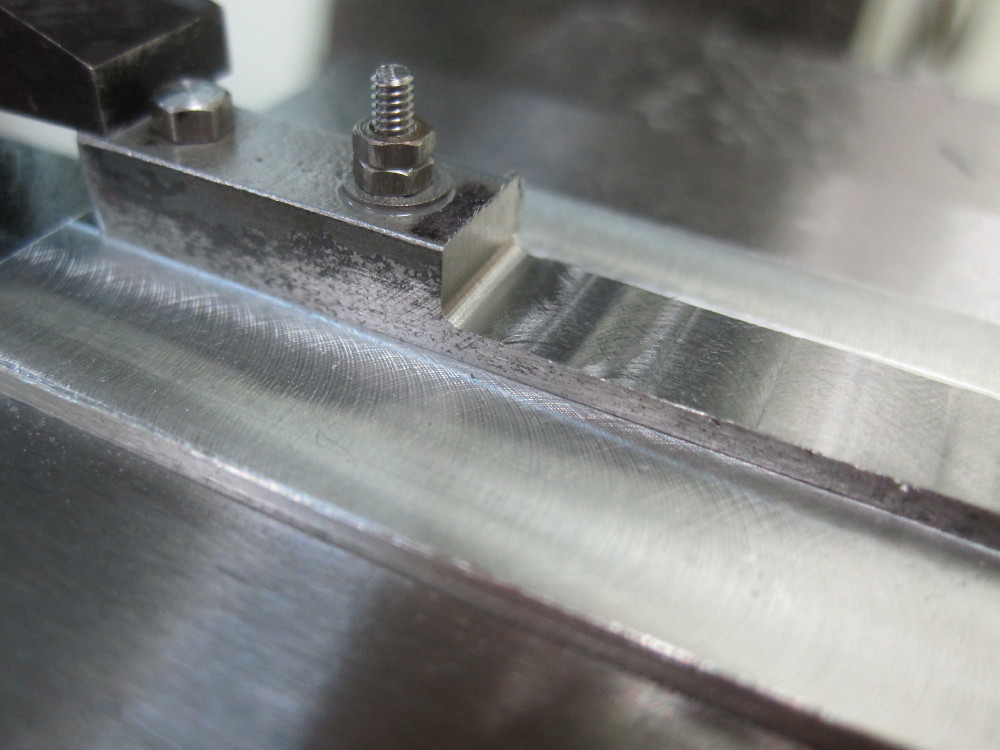

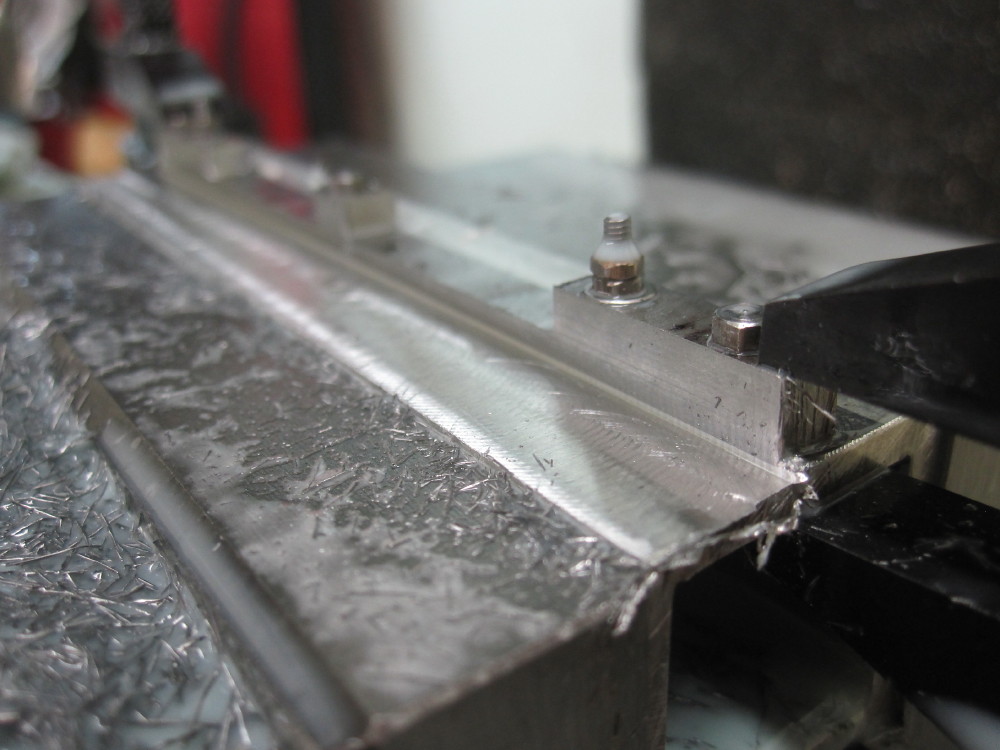

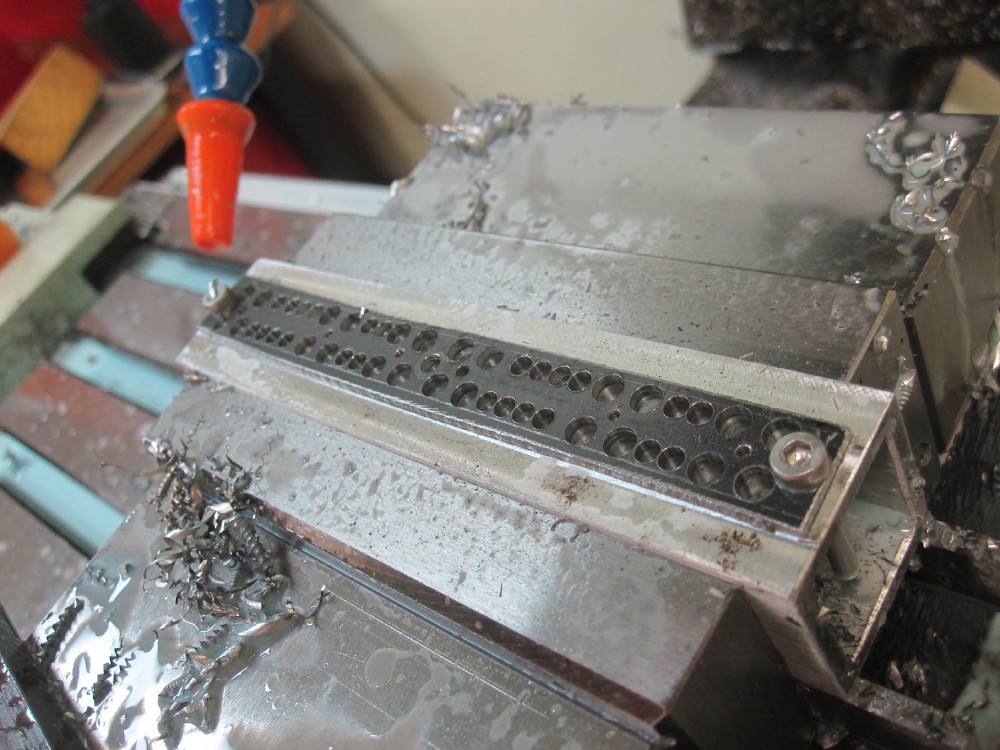

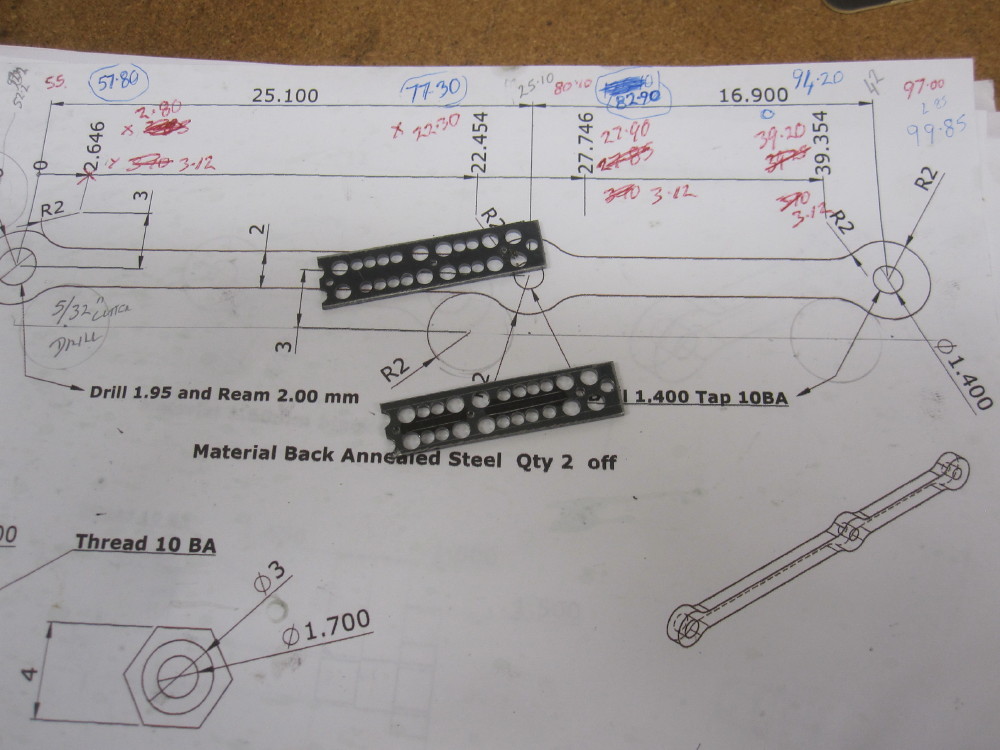

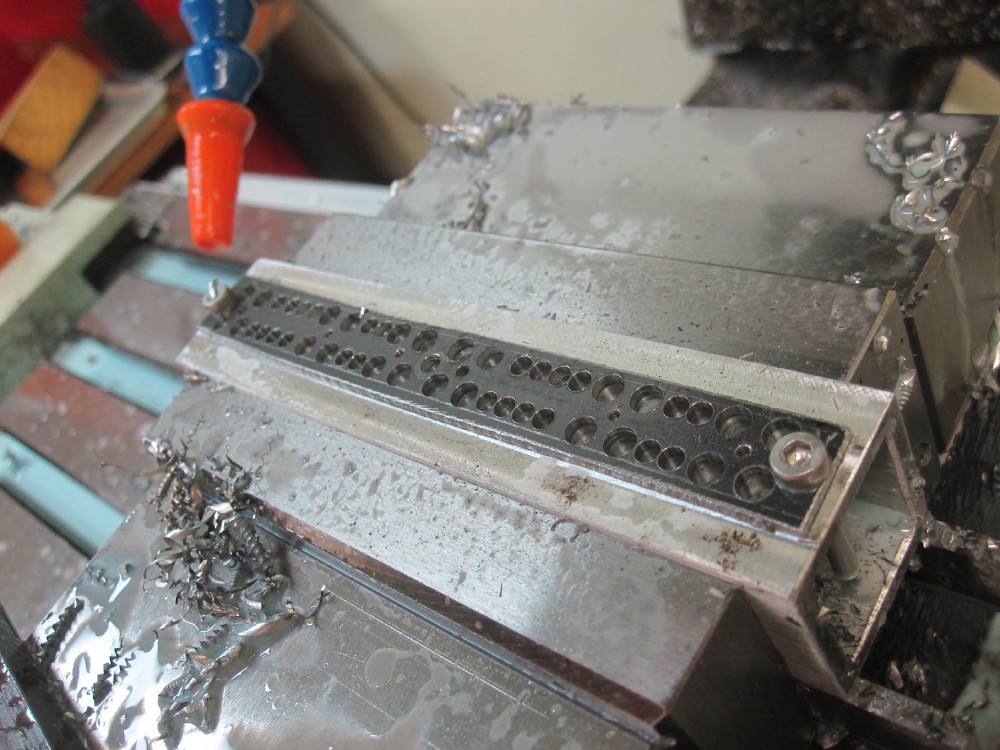

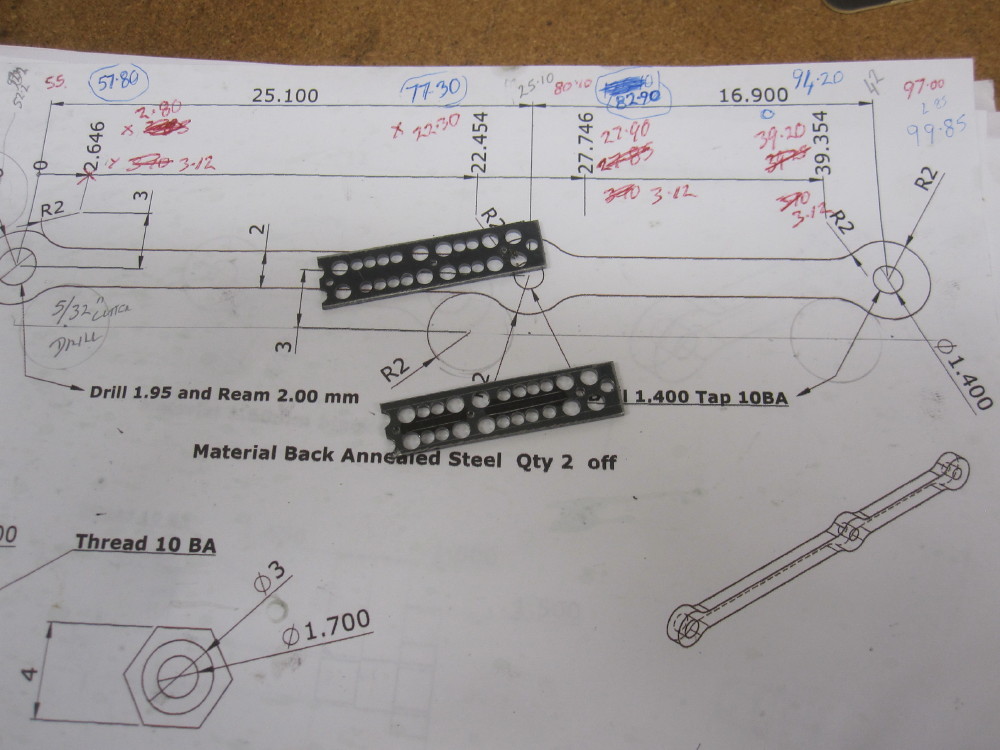

The alloy square section which has had 2 sides used for screwing the rods down when machining has a quick mill/face over one of the remaining sides to prepare it for the thinned 1/4" annealed steel piece to be screwed down on it. Drill and ream and tap threads. Two combination levers are in the one piece.

Thin out section with a cutter that has rounded corners.

Blow clear

Rounded corner

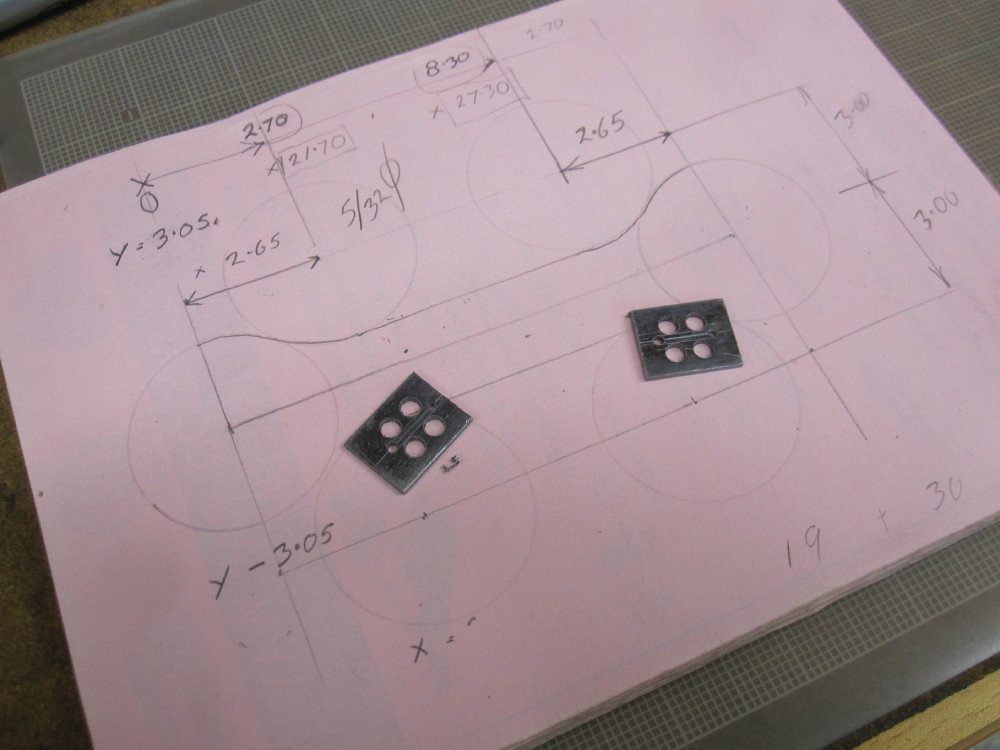

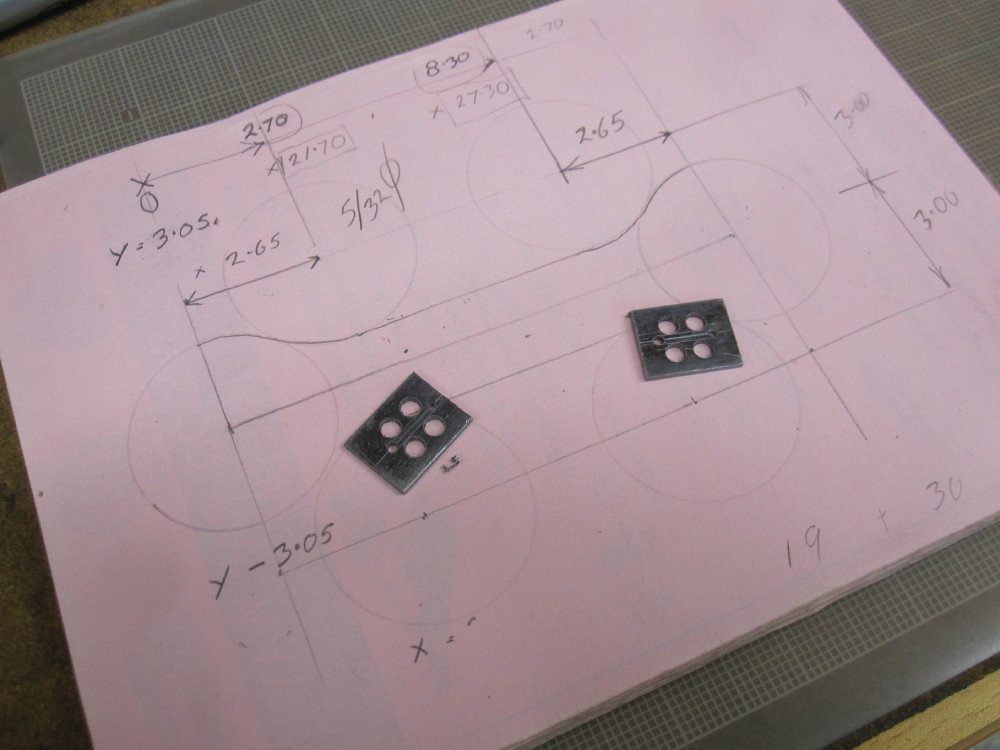

Now milling down the sides to bring it all down to 4.00mm The centre line of the holes is Y=0 so the DRO was used to work out where I am going, via notes and chook scratchings.

The tool makers clamps was just extra insurance for my sanity.

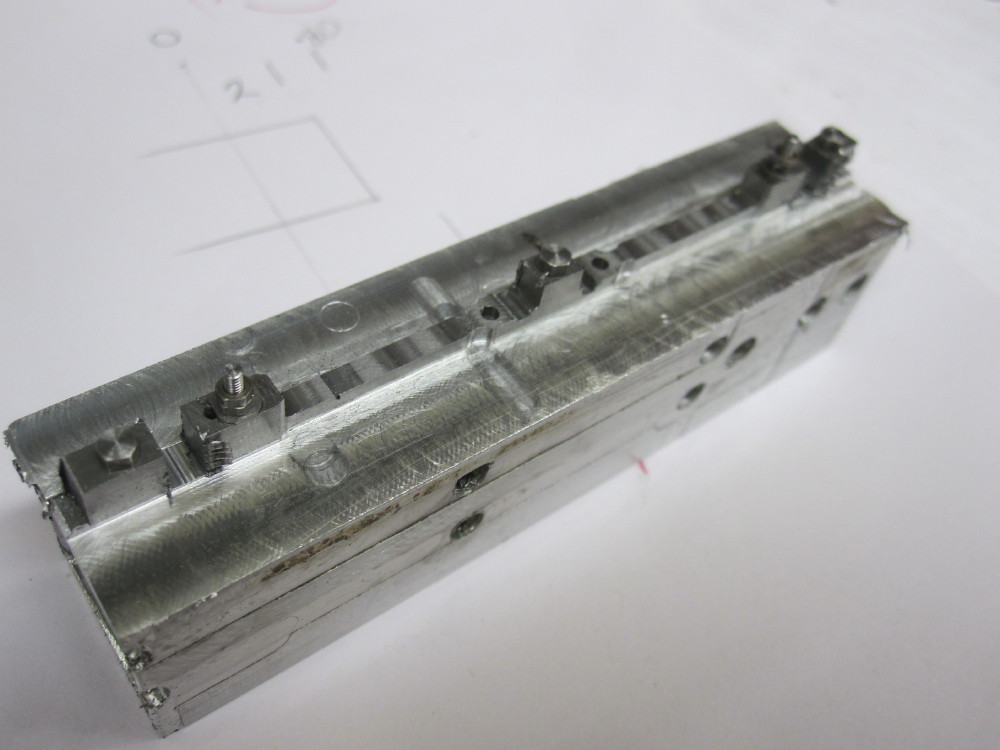

Work out a few more co-ordinates and start the outside profile. Those with CNC mills can have this easy, but for me it is "See and See" milling with DRO assistance.

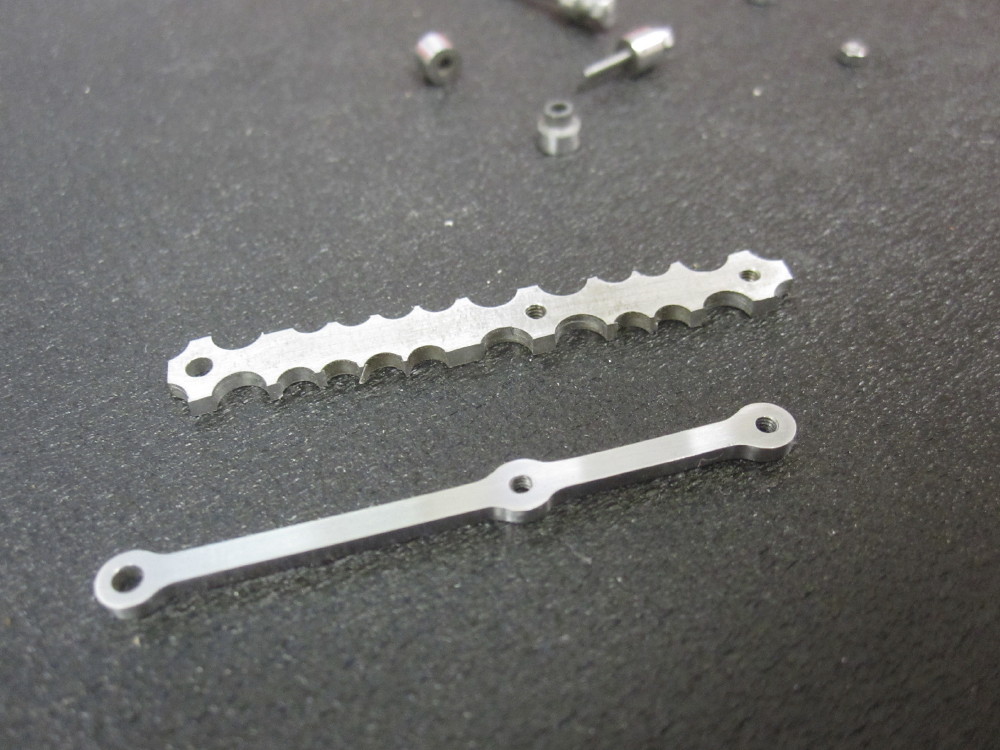

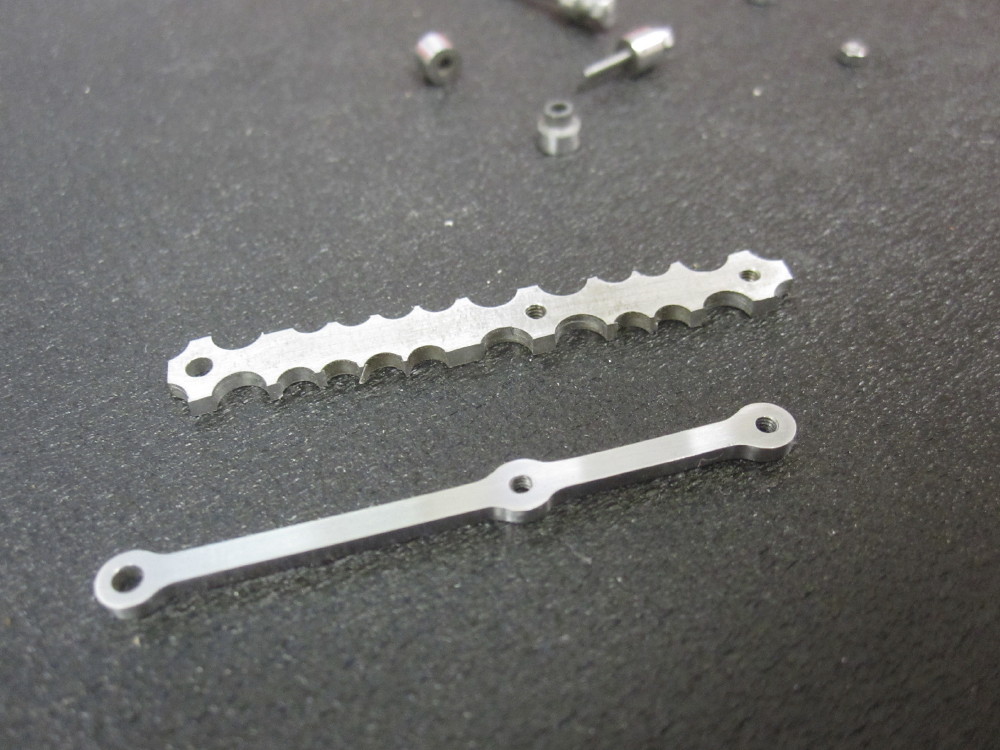

Looks like this when removed from the mill.

A bit more milling to get the taper, but a lesson learnt. NEVER NEVER buy cheap mill cutters. Brand new!

Badly made.

The moral is for me in OZ is "Sutton" or "Osborne" or similar breeds.

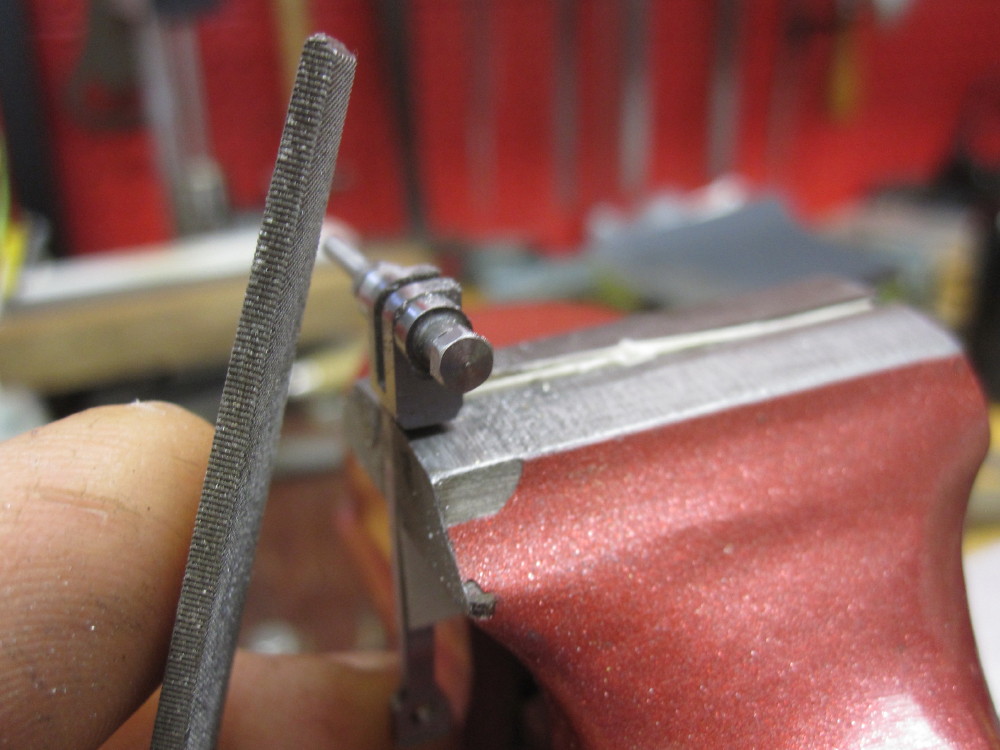

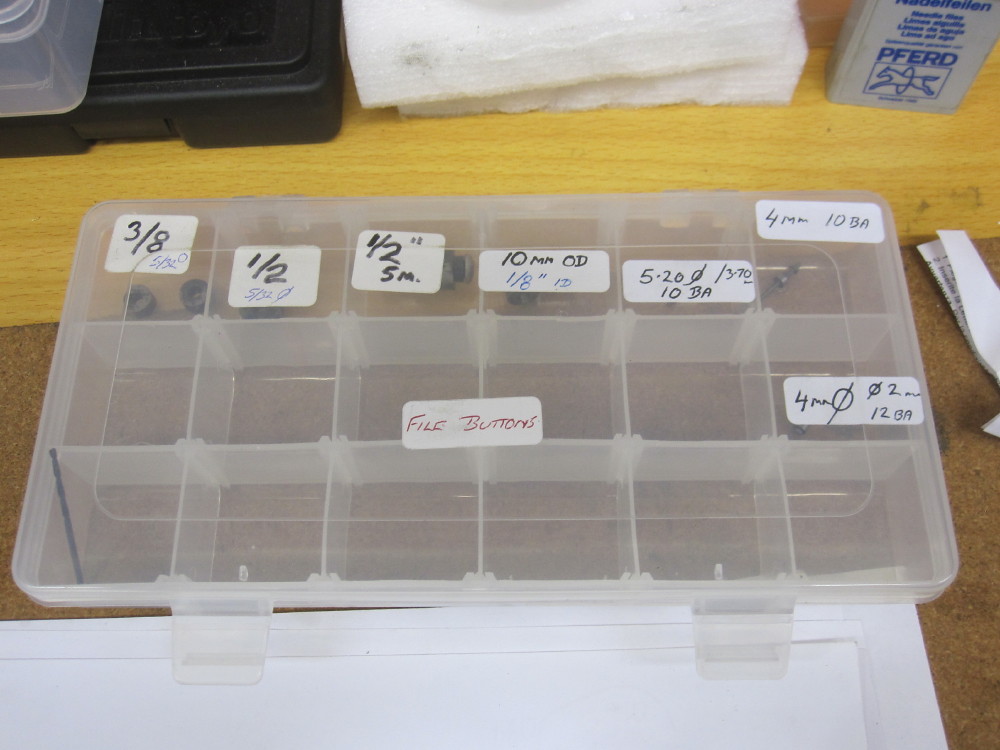

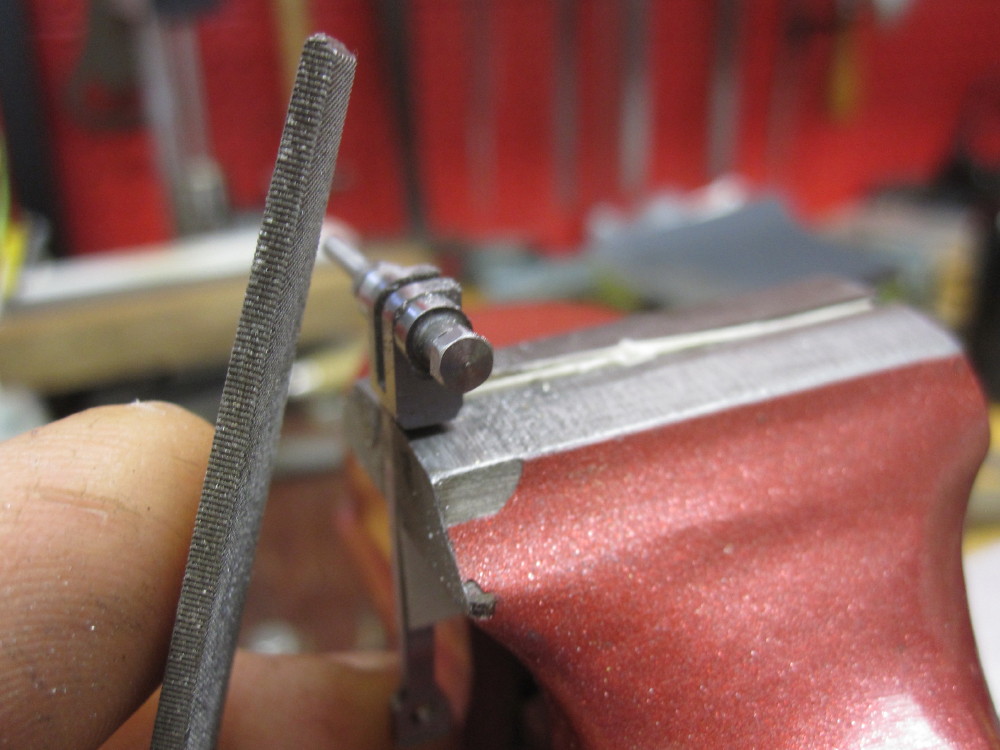

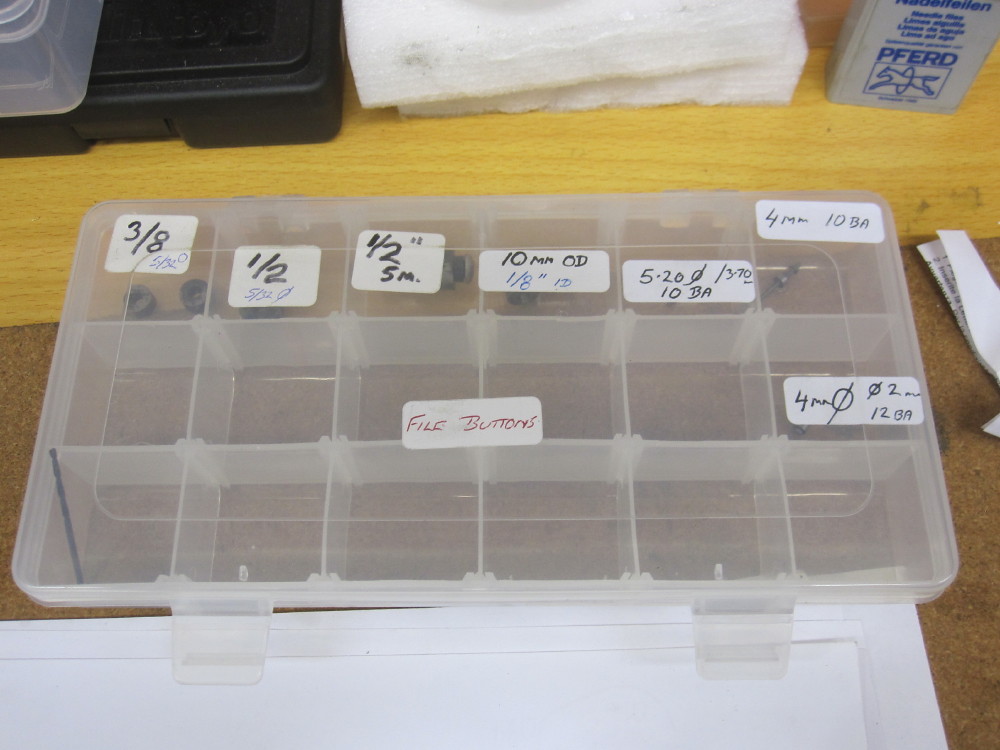

Made another set of filing buttons, 4mm OD with 2mm ID and 1.3mm hole for 12 BA screw x 2.

The collection is growing

a rub a dub rub with 600 and 1500 grit.

Oil them over, done, not perfect but I am pleased and satisfied.

Thin out section with a cutter that has rounded corners.

Blow clear

Rounded corner

Now milling down the sides to bring it all down to 4.00mm The centre line of the holes is Y=0 so the DRO was used to work out where I am going, via notes and chook scratchings.

The tool makers clamps was just extra insurance for my sanity.

Work out a few more co-ordinates and start the outside profile. Those with CNC mills can have this easy, but for me it is "See and See" milling with DRO assistance.

Looks like this when removed from the mill.

A bit more milling to get the taper, but a lesson learnt. NEVER NEVER buy cheap mill cutters. Brand new!

Badly made.

The moral is for me in OZ is "Sutton" or "Osborne" or similar breeds.

Made another set of filing buttons, 4mm OD with 2mm ID and 1.3mm hole for 12 BA screw x 2.

The collection is growing

a rub a dub rub with 600 and 1500 grit.

Oil them over, done, not perfect but I am pleased and satisfied.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Re: Llewellyn Loco Works #1

Brilliant precision engineering as always -even down to the corks for the oiling points.

Just out of curiosity - 5 servos? Regulator, reverser, ..... errr damper? ...injector? ......errr...?

Rik

Just out of curiosity - 5 servos? Regulator, reverser, ..... errr damper? ...injector? ......errr...?

Rik

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Regulator, reverser, cylinder drains, whistle and maybe one for the fire door to flip the door down to cool things if the safeties lift.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

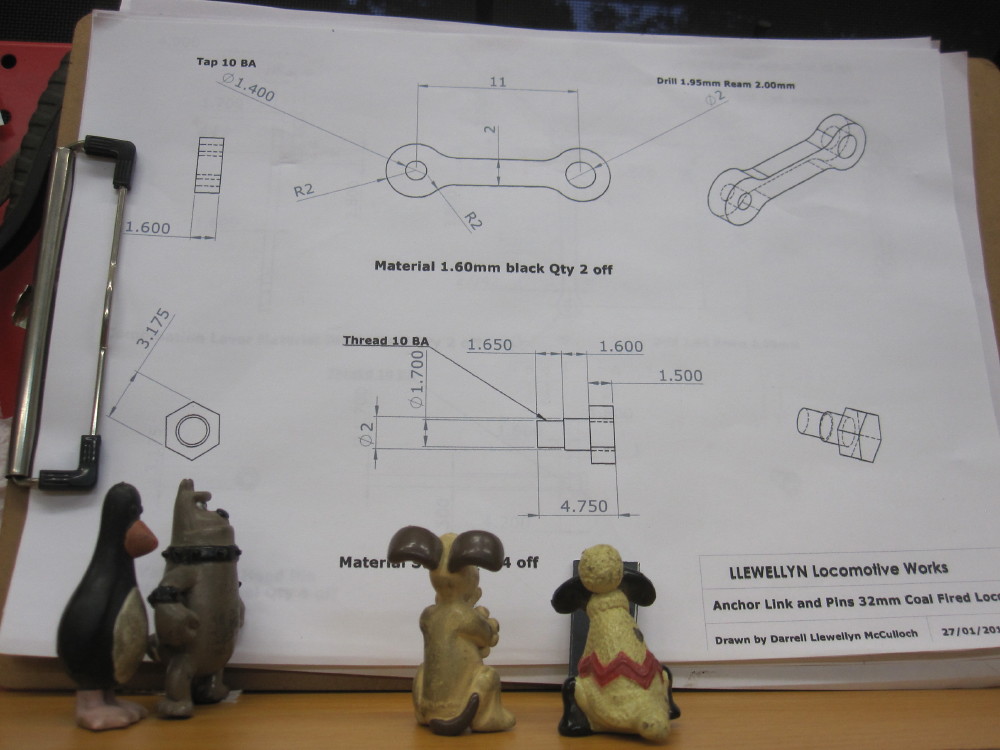

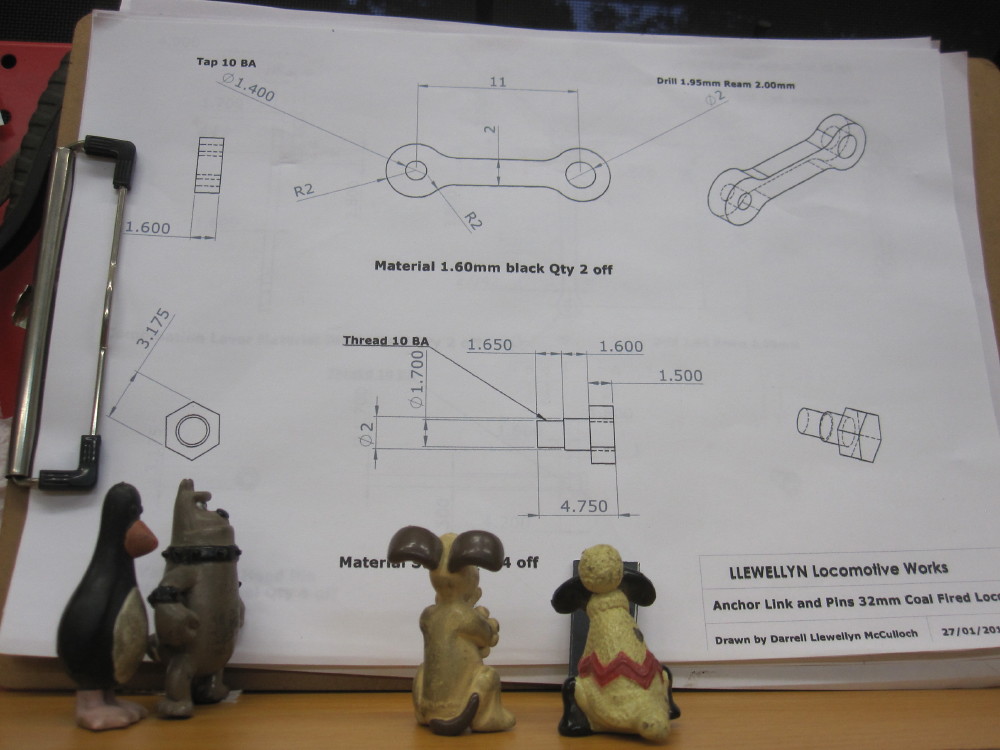

"What's next Gov ?"

"We will make a start on the Anchor (Union) links and then some pins, but give me a moment to think out the materials and tooling needed"

"We will make a start on the Anchor (Union) links and then some pins, but give me a moment to think out the materials and tooling needed"

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

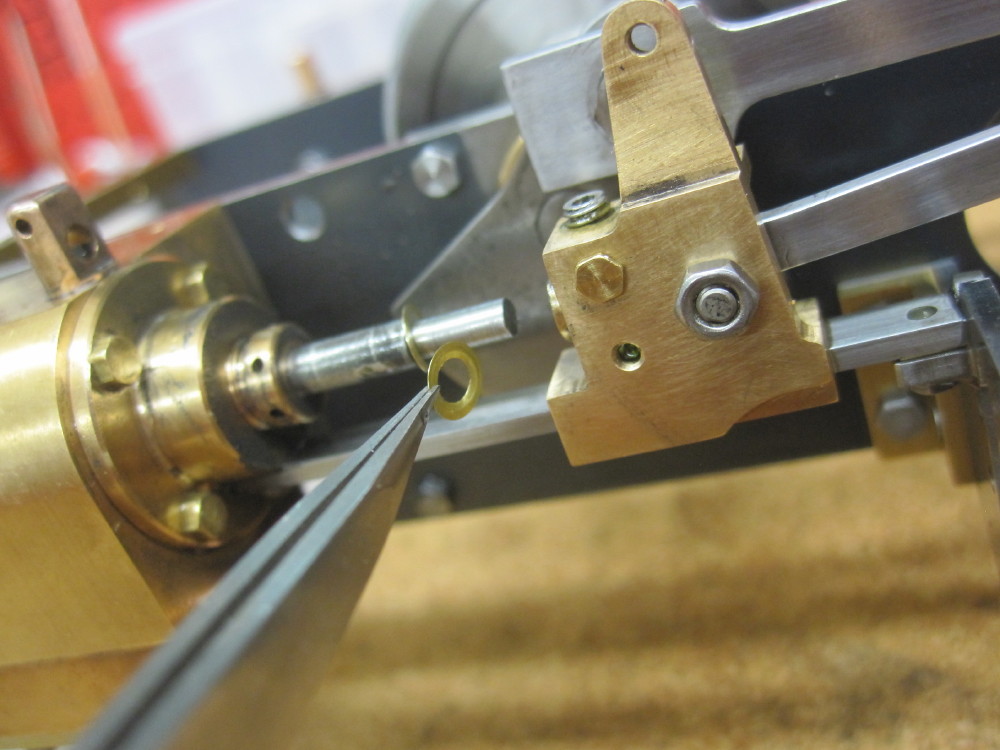

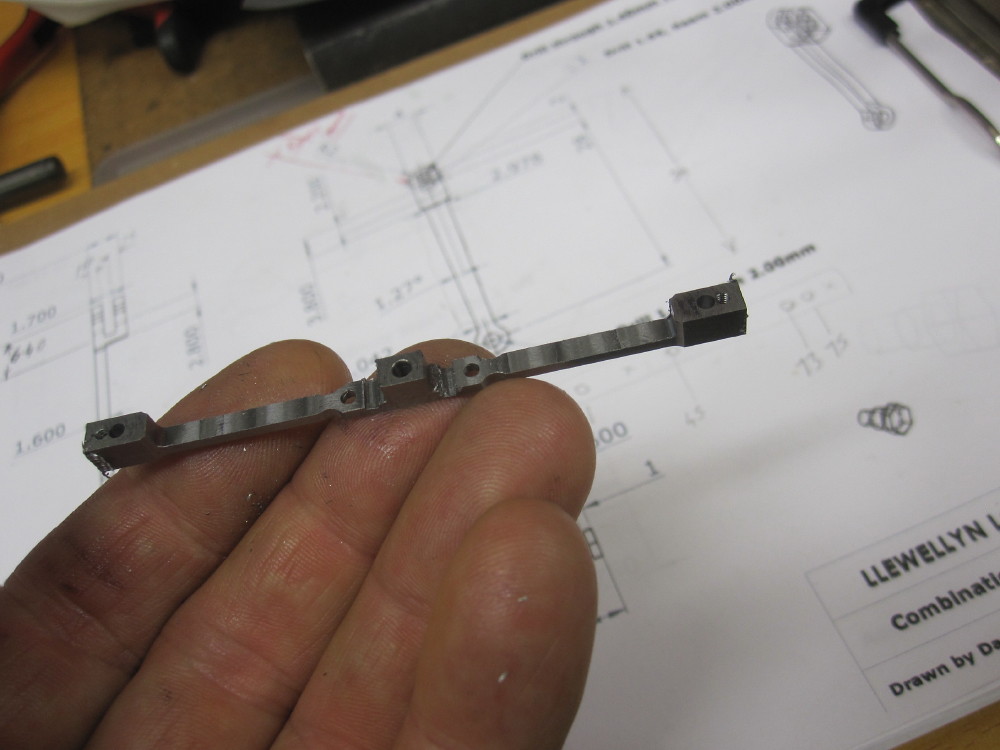

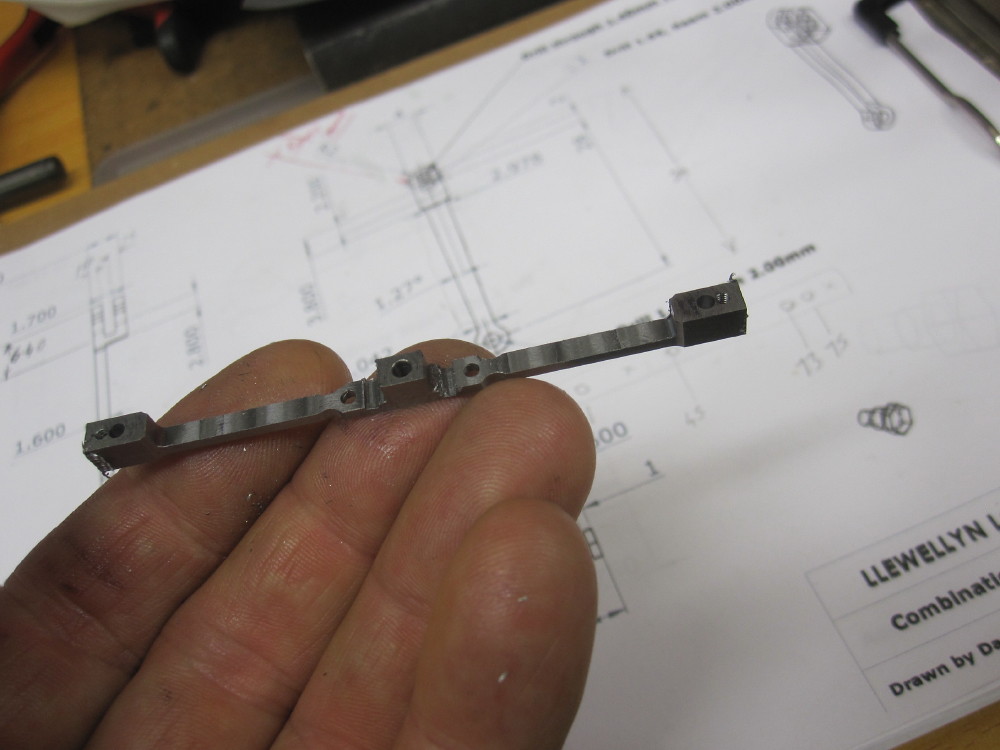

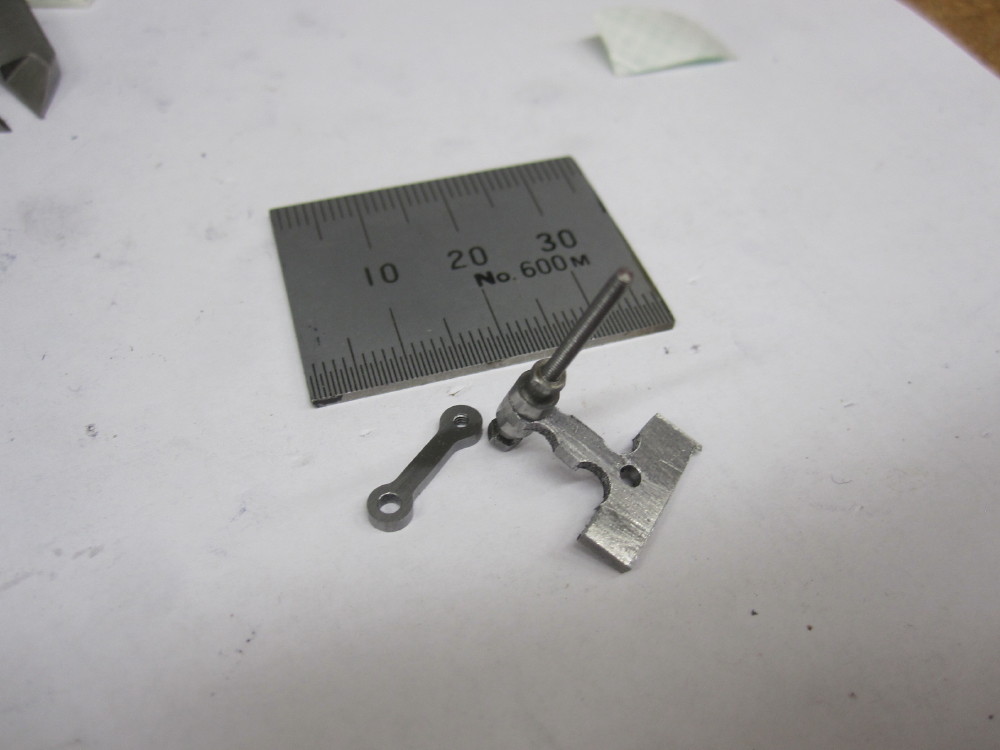

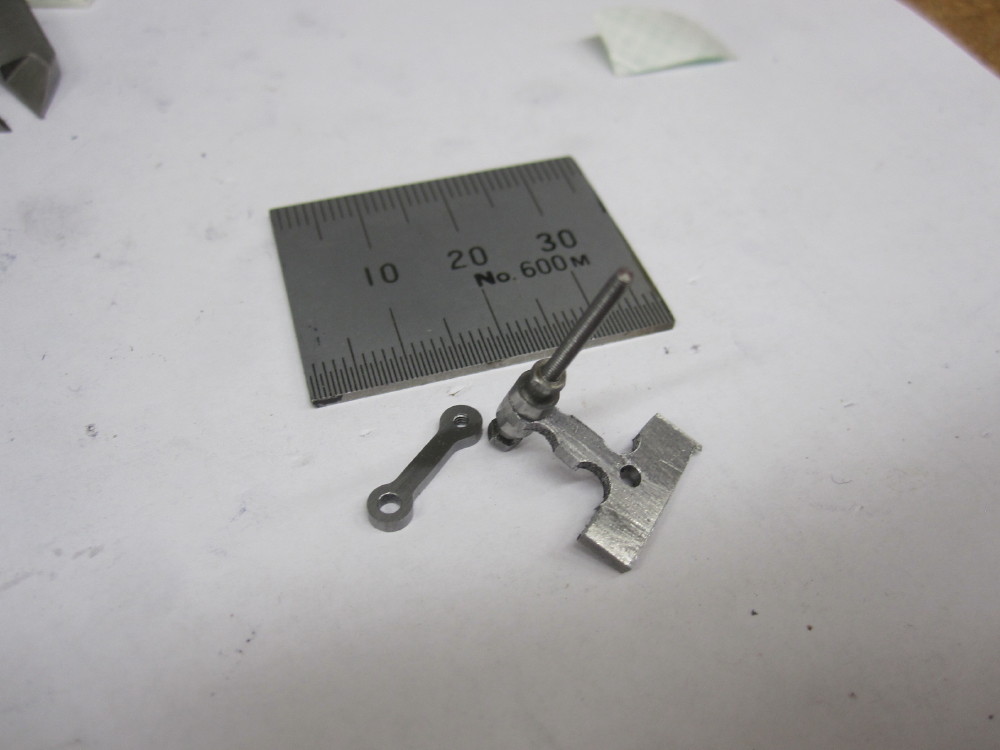

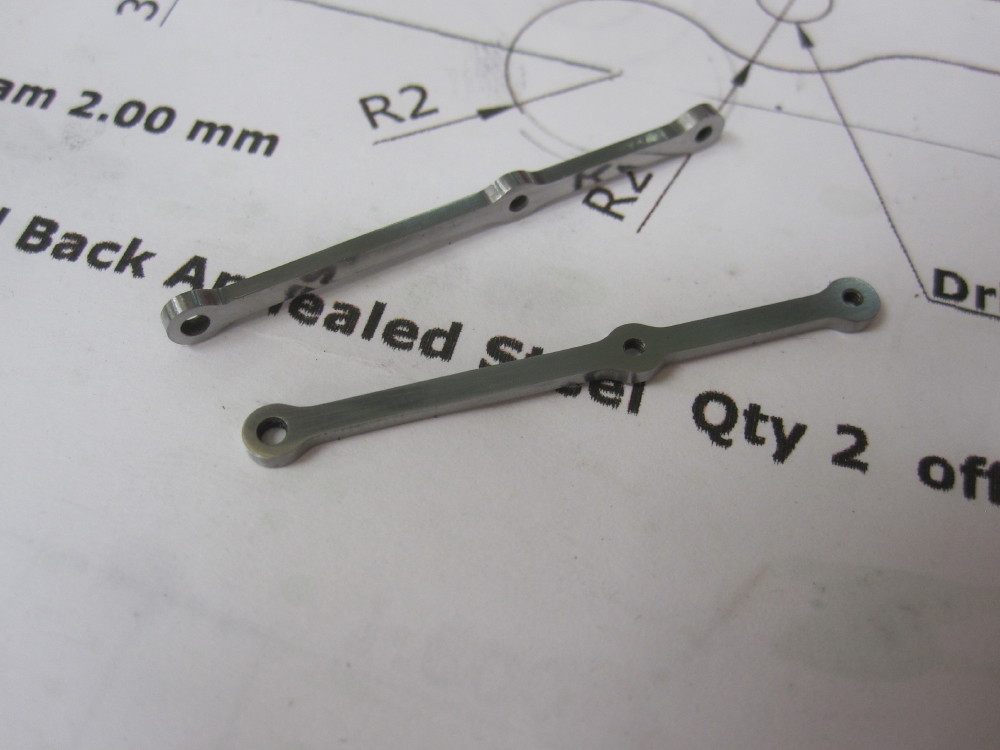

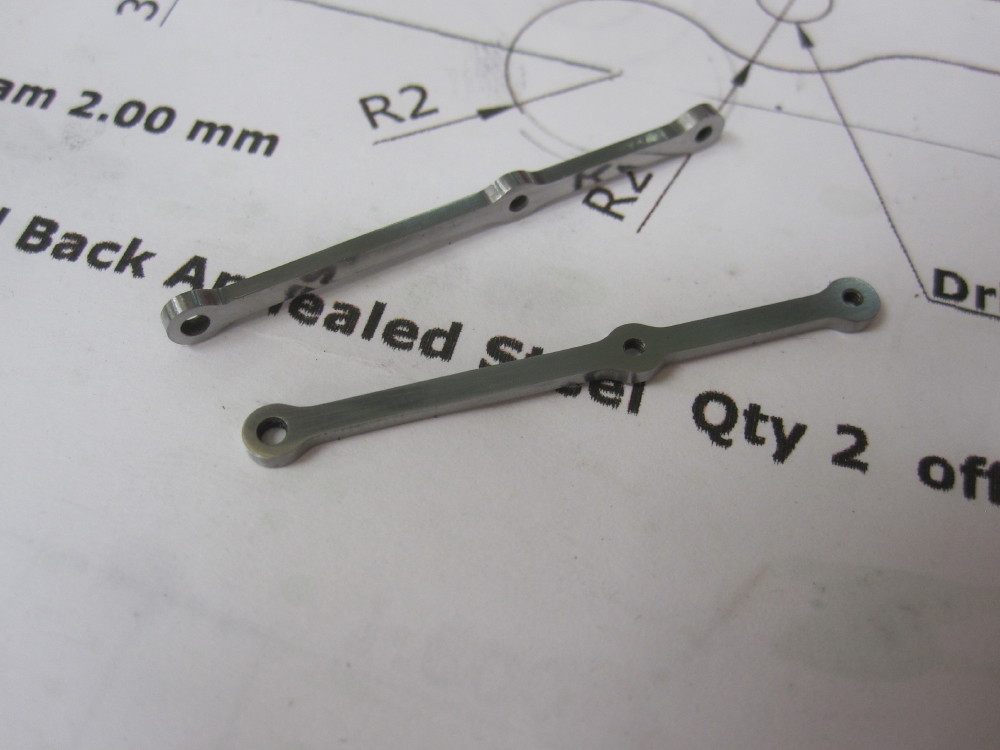

Fiddle here and there, plot the holes, add a wee bit of room here and there............

one Drag link done, (Queensland Railway term), anchor link, union link etc

last night while listening to ABC Jazz

one Drag link done, (Queensland Railway term), anchor link, union link etc

last night while listening to ABC Jazz

Last edited by Hydrostatic Dazza on Thu Feb 08, 2018 8:46 pm, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

I must have my loco do scale speeds. Watching a loco chug long with a train in tow is relaxing and pleasing to my eye and soul. The narrow gauge Mallard on Stock Bank impressions and then tearing around curves like a toy which has over dosed on amphetamines I cannot accept, so due to the axle pump I am fitting a Slomo equipped tender. Last night MAM was looking for inspiration for colours regards her Lady Ann kit (she has a Slomo and new wheels for it) while we were looking at the "Peter Angus Locomotive Book" I was pleasantly surprised to see the Burma Railways #9 loco on pages 105 to 109. What a lovely loco that is, in full size and small.

If I knew then what I know now I would be making a loco that looks a lot like the #9 , oh well.

The tender on the Burma Railways #9 is my inspiration to hide the Slomo into. I am still concerned how to fit all in and on the loco and tender without too much spoil to the back head, servos and related gear and water to feed to the water pump so, it seems that the Llewellyn Loco Works #1 is going to be a tender tank loco.

If I knew then what I know now I would be making a loco that looks a lot like the #9 , oh well.

The tender on the Burma Railways #9 is my inspiration to hide the Slomo into. I am still concerned how to fit all in and on the loco and tender without too much spoil to the back head, servos and related gear and water to feed to the water pump so, it seems that the Llewellyn Loco Works #1 is going to be a tender tank loco.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Inspired by emails and pictures I found

https://www.scran.ac.uk/database/record ... chdb=scran

and so I paid my 8.50 quid and down loaded a high res pic.

Also via some emails a fellow afflicted victim is also contemplating a 16mm Burma Mines Railway #9 and he is well acquainted with a chap who has recently built a 2.5" gauge version. So my cunning plan is to use # 9 for my inspiration to draw up and make a tender for Llewellyn Loco works # 1.

What a lovely tender # 9 has with it's awning, no doubt very welcome in the tropical down pours.

We will see if I make a mess of this loco and it steams and moves as I desire, if not, try again.

https://www.scran.ac.uk/database/record ... chdb=scran

and so I paid my 8.50 quid and down loaded a high res pic.

Also via some emails a fellow afflicted victim is also contemplating a 16mm Burma Mines Railway #9 and he is well acquainted with a chap who has recently built a 2.5" gauge version. So my cunning plan is to use # 9 for my inspiration to draw up and make a tender for Llewellyn Loco works # 1.

What a lovely tender # 9 has with it's awning, no doubt very welcome in the tropical down pours.

We will see if I make a mess of this loco and it steams and moves as I desire, if not, try again.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

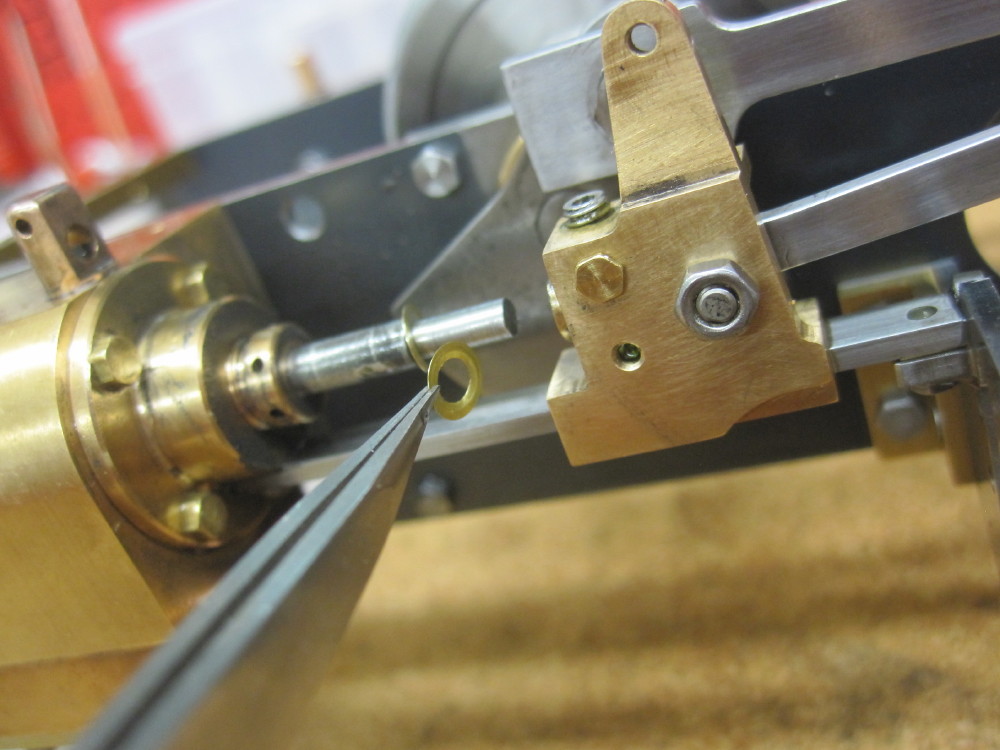

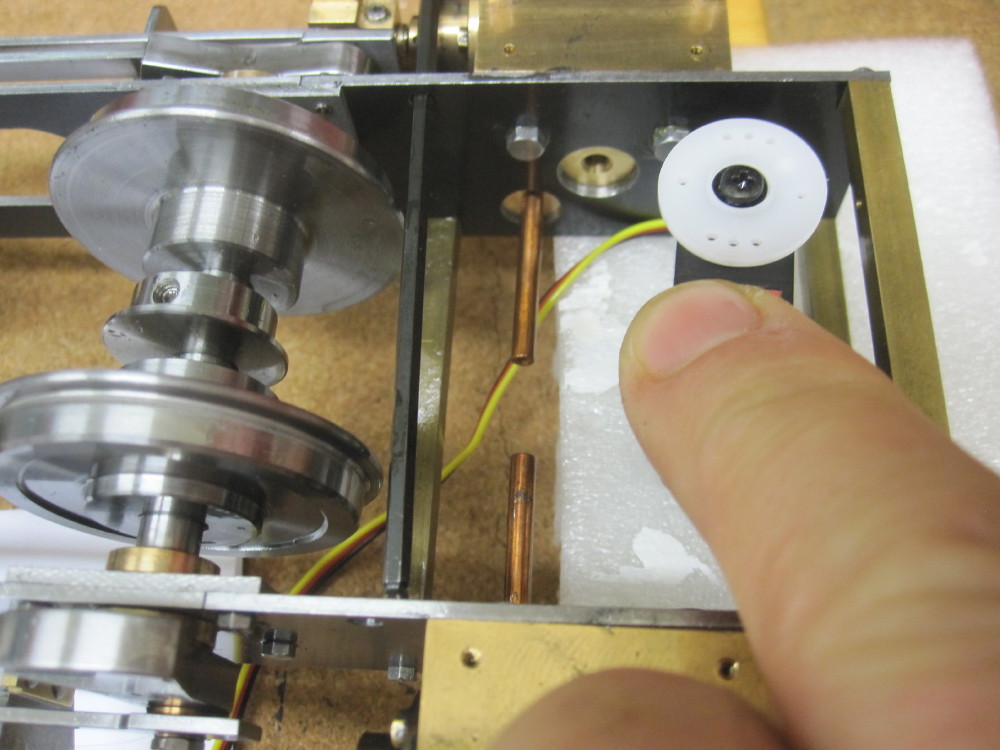

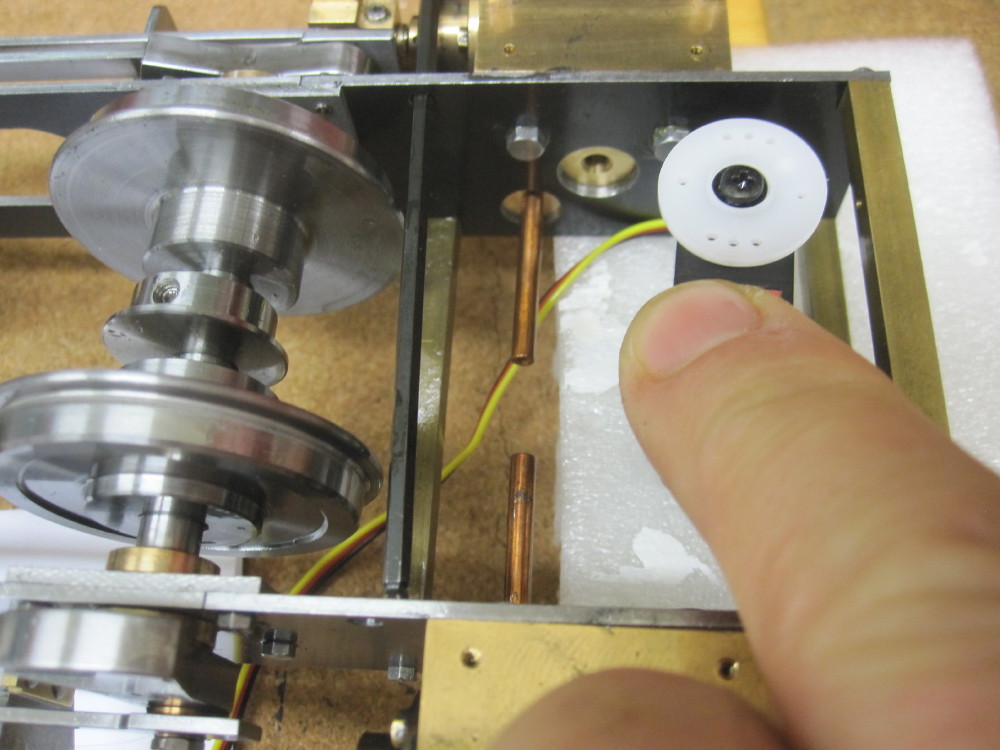

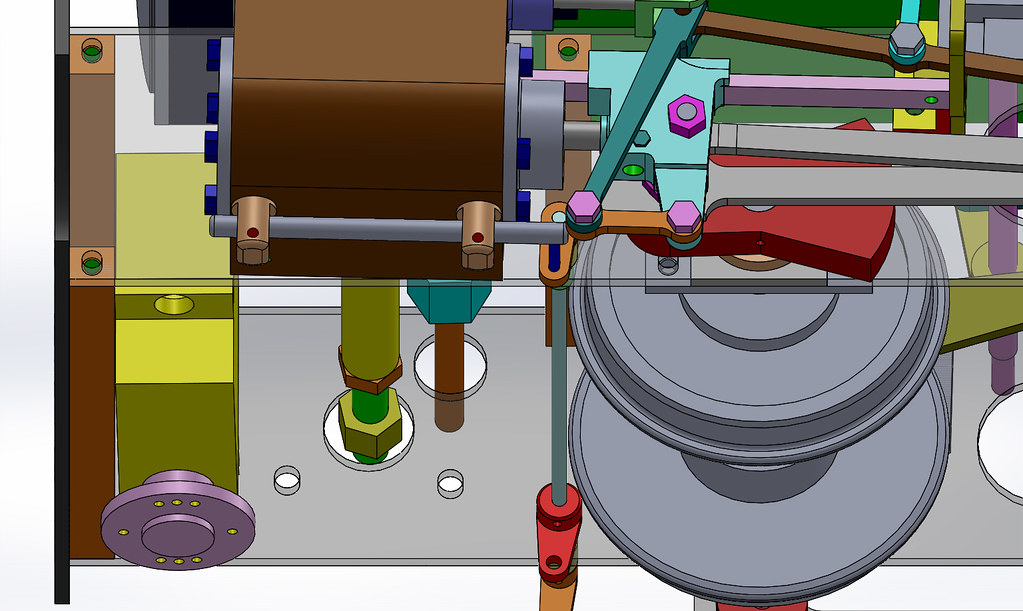

The Llewellyn Loco works drawing office has made a boo boo, the cylinder drain operating shaft fouls the wheel treads, just needed one millimetre. A cranked and or two piece shaft is now required. On a happier note, the cylinder drain servo fits nicely under the front plate. Its bracket will secured by the four Buffer beam screws.

Last edited by Hydrostatic Dazza on Sun Feb 11, 2018 8:28 pm, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Sunday's entertainment was radius rods.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

There are pics and mentions on pages 3, 4, 5 and ? of this thread.

I followed Brian Wilson's words and music as he mentioned them in the Book Steam Trains in the garden. By careful cross drilled passages I changed the drains to exhaust sideways rather directly downwards as per the B.W drawings, with the intention of not blowing grot all over the engine.

Brian Wilson leaves the linkages up to what ever. I lined the geo up but shaft diameter I had drawn was 1.60mm which just cleared the leading flanges, it is stiff enough but a bit small to cross drill for pinning so a bigger diameter just rubs. So I rework of the of the shaft design is underway and I think I have a solution that will take me a week to make and then test. The Servo has a short rod to the shaft to the crank that rotates the shaft via a crank which cranks the drain rods.

Last edited by Hydrostatic Dazza on Mon Feb 12, 2018 2:12 am, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

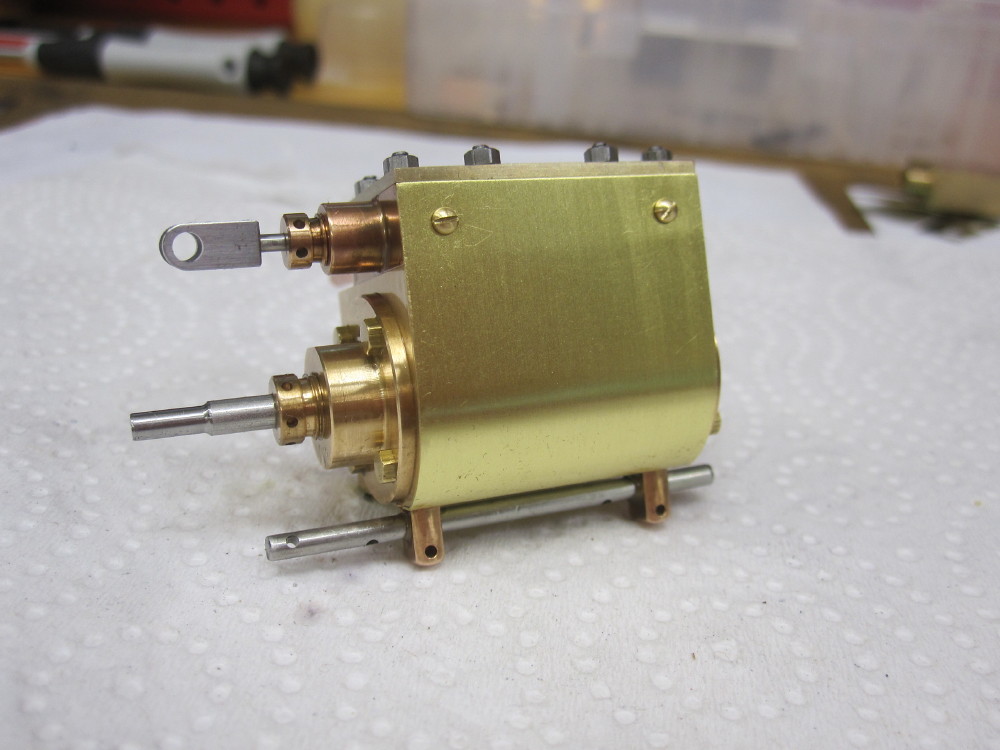

I did not use brass but Phosphor bronze for the drains, so wear should be slower. The only brass is the hex heads and cladding, the rest is LG2 bronze.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Who is online

Users browsing this forum: No registered users and 8 guests