Page 2 of 2

Re: Flexible track

Posted: Wed Nov 07, 2018 10:28 am

by IanC

tom_tom_go wrote: ↑Sun Nov 04, 2018 1:10 pm

I think that's the difference, due to my small garden I had to fit curves well under 5ft!

My curves too will be well under 5ft. I shall be forming curves round a template.

Re: Flexible track

Posted: Wed Nov 07, 2018 10:38 am

by tom_tom_go

You can use AnyRail software to print out 1:1 scale templates:

www.anyrail.com

Re: Flexible track

Posted: Wed Nov 21, 2018 7:36 pm

by quilkin

Big Jim wrote: ↑Thu Nov 01, 2018 7:31 pm

A meccano rail bender would be a nice project to write up for this forum.......

I have now tried! Not entirely successful.

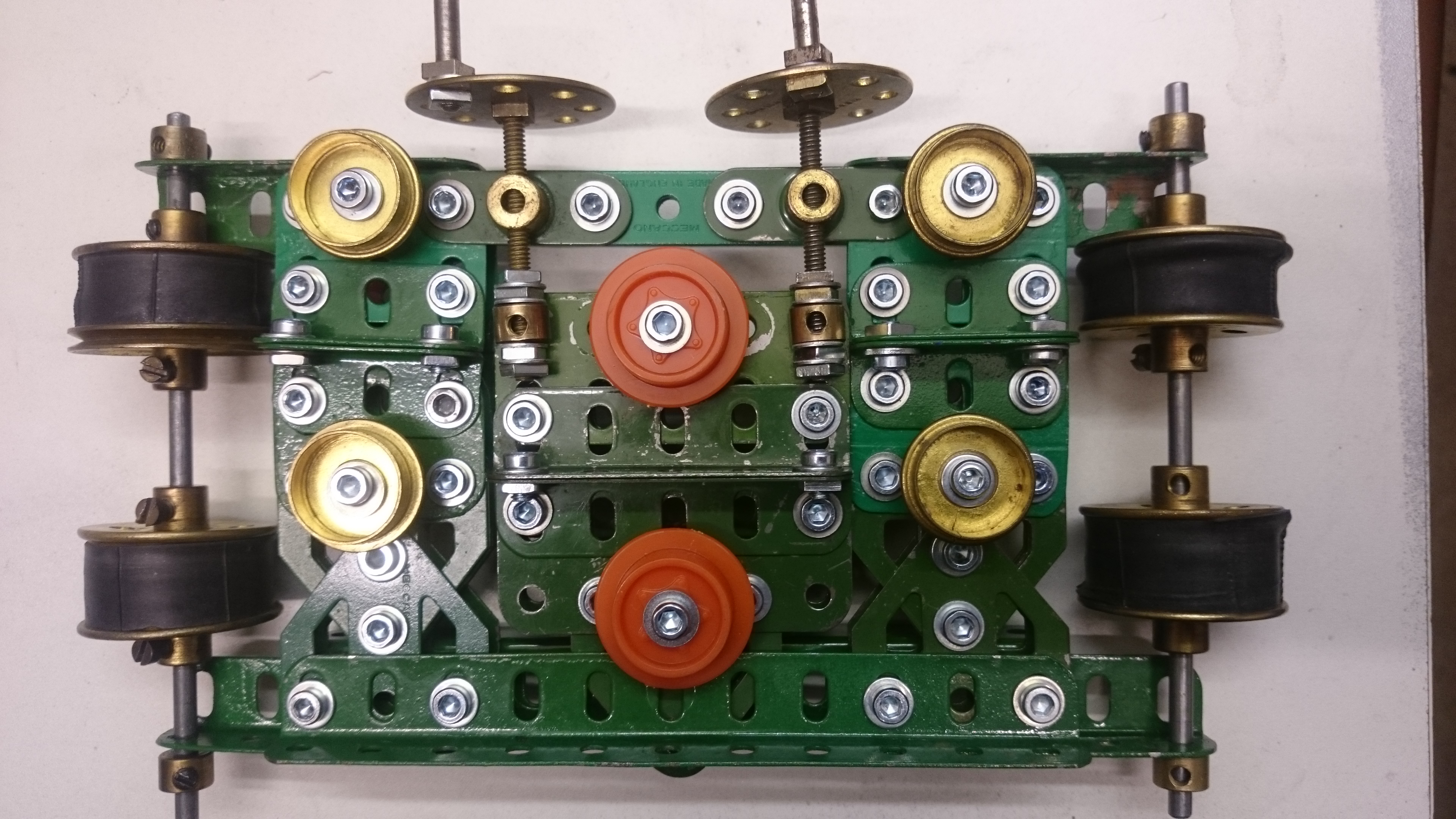

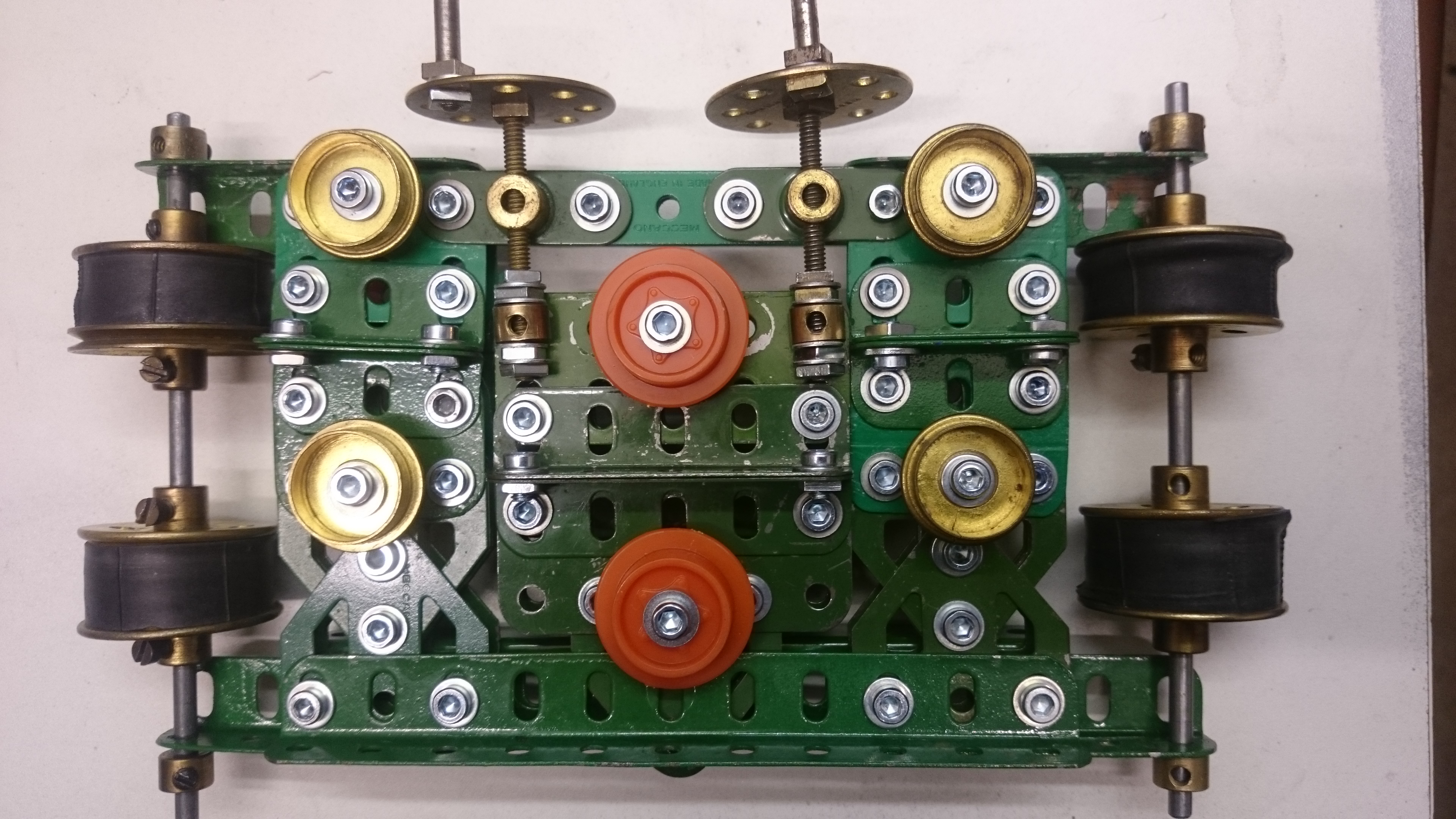

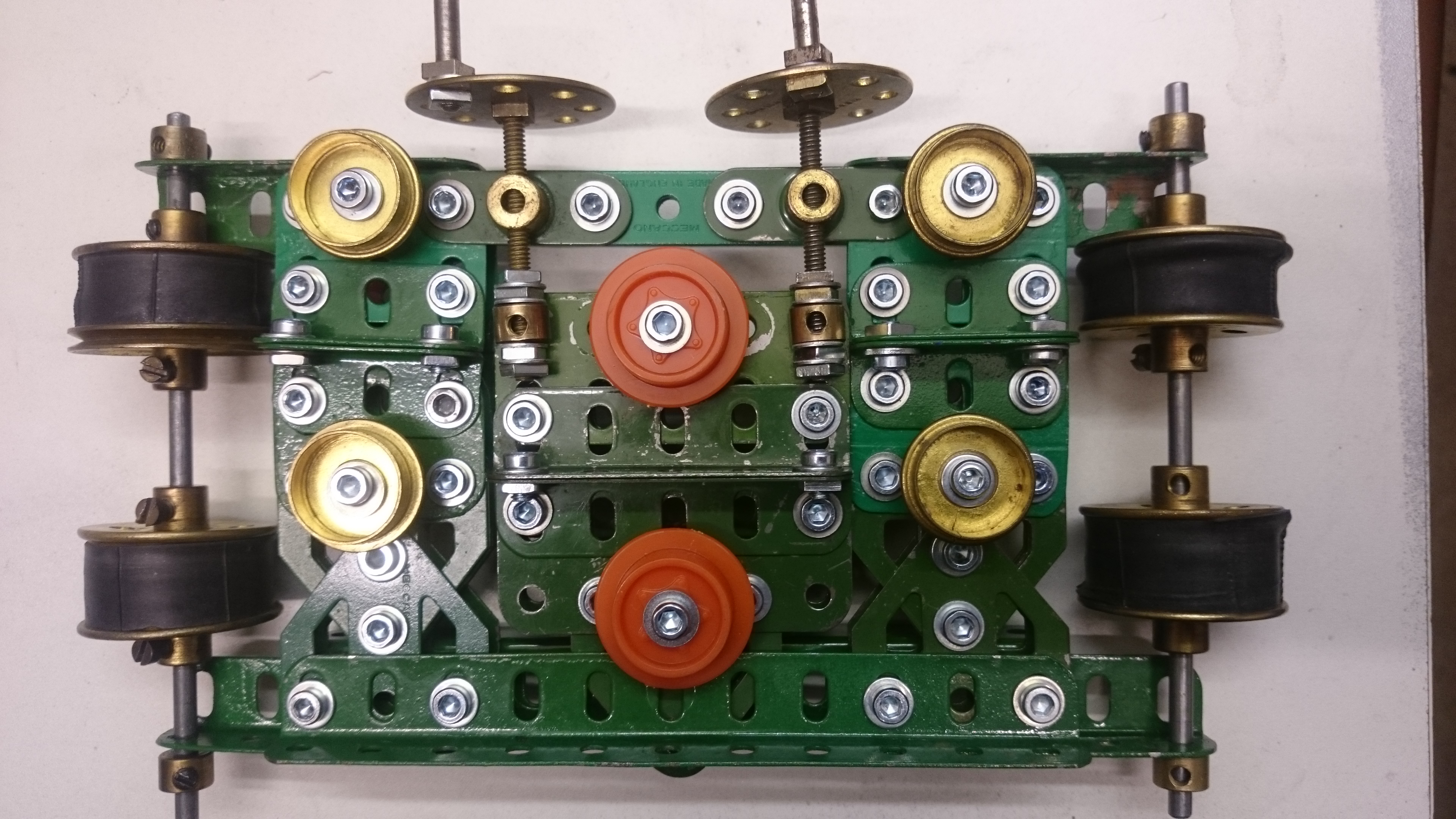

The track runs between the brass and the plastic flanged wheels. It does bend the track a little, but the force required is too much for rather feeble Meccano bearings (not visible in the photo is the fact that all the reamework strips are 7 or 8 parts thick to help rigidity).

But what the exercise has shown me is that any bender designed for use with the sleepers in place is going to be very inefficient, because there's ony 4mm clear height on the rail sides to allow any wheel to push against. The rail itself is 8.5mm high so we can only exert pressure on less than half of it. This may possibly end up with distorting the width of the rails?

Re: Flexible track

Posted: Wed Nov 21, 2018 7:58 pm

by tom_tom_go

I take the rail out of the sleepers before bending, I don't think you should be trying to bend both rails at the same time while attached to sleepers...

Re: Flexible track

Posted: Thu Nov 22, 2018 7:57 am

by ge_rik

Full marks for trying. It certainly is a marvellous looking beastie.

Rik

Re: Flexible track

Posted: Thu Nov 22, 2018 9:26 am

by pandsrowe

When I first made my rail bender I was amazed at how much force was required to bend the rail and in fact my initial device did not work. When you think how relatively easy it is to bend the rail around your knee for example but of course there is a fair amount of leverage available when doing it like that, imagine trying to bend it just using finger pressure, much less leverage available because you are working over a very short section which is how a rail bender is working, hence lots of force required. One thing that I have thought about making is a "Jim Crow" as I don't believe that they are available as a commercial item, I feel that a device like that would give quite precise control over the bend of the rail but getting repeatability might be an issue. Has anyone here tried this?

Re: Flexible track

Posted: Thu Nov 22, 2018 2:25 pm

by IrishPeter

Brass is a lot more difficult to bend than aluminium, and in the main when I have been laying flexible track it has been the latter, so knee bending - especially given my usual 5' minimum radius - was not an issue. Brass on the other hand... that was a case of borrow a mate's rollers, especially as I was laying a 3'6" radius curve at the time.

A Jim Crow is a slow way of doing it. On a garden line you can chalk the radius you want on the path and be patient, then it is a very accurate way of doing it. I am afraid my experience of Jim Crows is confined to 12" to the foot scale, so I cannot tell you how it would work with code 332 - as opposed to 30lbs/yard!

Cheers,

Peter in Va

Re: Flexible track

Posted: Thu Nov 22, 2018 4:29 pm

by Big Jim

I have now tried! Not entirely successful.

The track runs between the brass and the plastic flanged wheels. It does bend the track a little, but the force required is too much for rather feeble Meccano bearings (not visible in the photo is the fact that all the reamework strips are 7 or 8 parts thick to help rigidity).

But what the exercise has shown me is that any bender designed for use with the sleepers in place is going to be very inefficient, because there's ony 4mm clear height on the rail sides to allow any wheel to push against. The rail itself is 8.5mm high so we can only exert pressure on less than half of it. This may possibly end up with distorting the width of the rails?

Superb job, sorry to read it is not as effective as it could be. As others have said, it may be worth playing around with loose rail to see what happens.

Re: Flexible track

Posted: Tue Nov 27, 2018 5:18 pm

by Robert Hammond

Flexible track is definitely the sort to use, but a rail bender is a must. They can be a bit pricey, but for my Peco track I bought just the three rollers with the correct profile for the Peco rail, mounted the 2 outer ones with bolts onto a block of wood so that they would turn, and mounted the centre one on another block, then bolted the 2 blocks onto each jaw of a workmate. You then adjust the separation of the jaws to get the required radius of curvature of the rail. Easy, cheap and it works.