MAM's painting isn't bad either.....

Llewellyn Loco Works #1

Re: Llewellyn Loco Works #1

I do love that loco you drive Dazza, it's truly a beautiful loco...

MAM's painting isn't bad either.....

MAM's painting isn't bad either.....

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

Re: Llewellyn Loco Works #1

Nice trick with copper rivets.

Looking forward to seeing the boiler pickled and cleaned up. There is something about copper when it's all bright and new.

Looking forward to seeing the boiler pickled and cleaned up. There is something about copper when it's all bright and new.

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

I will try to sort pics in the next 24 hourstom_tom_go wrote: ↑Mon Jul 15, 2019 8:43 am Nice trick with copper rivets.

Looking forward to seeing the boiler pickled and cleaned up. There is something about copper when it's all bright and new.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Lovely winter mornings at Gympie, over night down to Zero, foggy mornings, then lovely clear sunny and warm days, which beats the 40 + degree summer days with over 50 in the cab.

Last weekend, a couple of light-ups, driving and firing and Sunday of guarding. Living the dream.

Last weekend, a couple of light-ups, driving and firing and Sunday of guarding. Living the dream.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

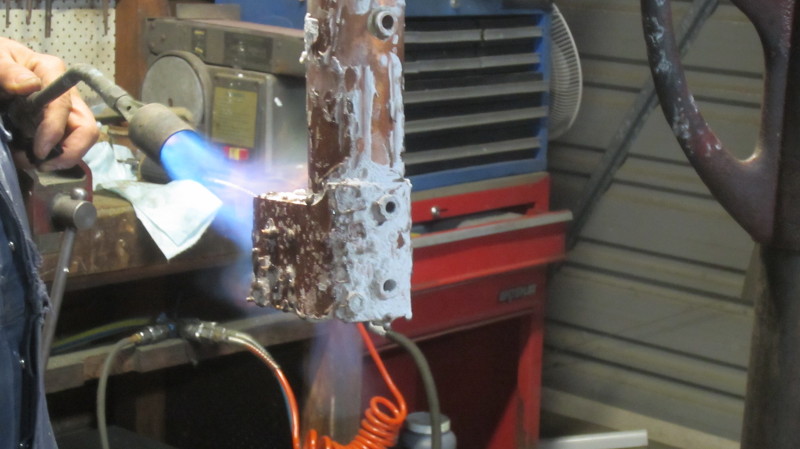

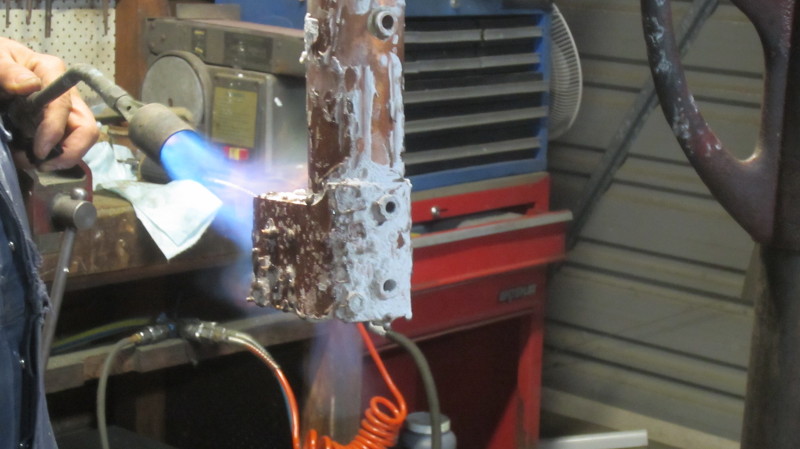

The weekend plan is to cook the back head in place. All seems to be structurally as it should be and square. I poured a lot of silver into this assemblage of copper, I was not all that pleased with the neatness, but that is an adjustment to working with copper rather than steel.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

Re: Llewellyn Loco Works #1

Love the photos Dazza, especially the one with all the steam coming from Gympie....

The soldering looks neat to me also. You won't see the inside stuff will you......

The soldering looks neat to me also. You won't see the inside stuff will you......

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

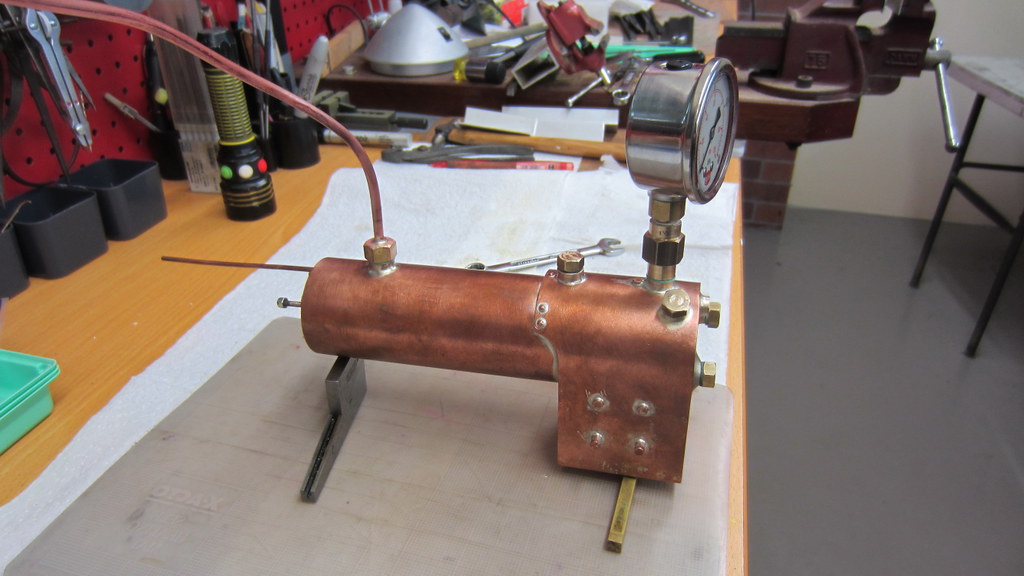

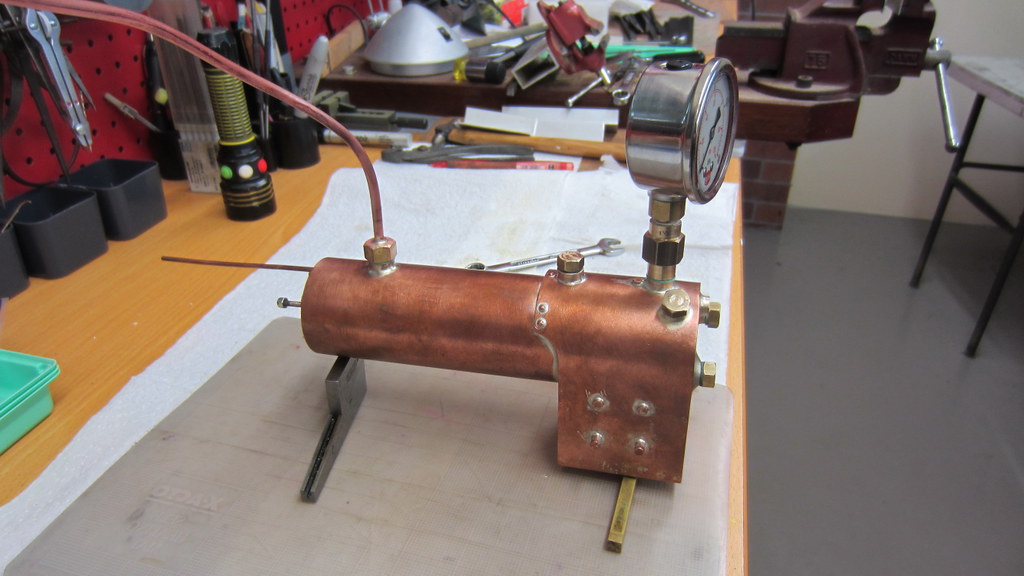

Finished cleaning up the boiler. When I was brazing in the back head I had the smoke box end up and flowing the filler in, the water gauge bush actually touches the inner box and or very close to the outer wrapper and silver flowed and flowed with out me noticing and I got a huge fillets on the outside of the bushes which I discovered when I flipped it over. Working on my hydro test rig now. Off to Gympie tomorrow for three days at the Rattler. One day cleaning 974 and then two days of firing and driving, living the dream.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- tom_tom_go

- Driver

- Posts: 4824

- Joined: Wed Feb 23, 2011 3:08 am

- Location: Kent, UK

- Contact:

Re: Llewellyn Loco Works #1

Nicely done and it looks beautiful all cleaned up!

I do like a newly finished boiler.

I do like a newly finished boiler.

Re: Llewellyn Loco Works #1

Impressive neat work.

Don

Don

Re: Llewellyn Loco Works #1

Nicely done....

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- BorisSpencer

- Fireman

- Posts: 251

- Joined: Thu Apr 05, 2018 2:36 pm

- Location: East Northants

Re: Llewellyn Loco Works #1

I don't comment on many threads, but that is a lovely piece of work Dazza.

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Thank you every for your kind comments. They are much appreciated. I just try to do my best and to share the fun.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Called into my clubs "Track and Tent" run day, ground and elevated track. To be honest, riding, driving around with no passengers does not inspire me, I need a purpose to drive and run a loco, small or full size. Not to take away from the chaps enjoying them selves, but for this spud it is the passengers that make it all a real purpose to function. Perhaps I am more interested in making stuff when I can scrape the time for it and my time line to gain the knowledge and skills to make my magnum opus one day. Any how I bought some materials from a trade supplier. Sunday was in the Red Room and complete the hydro test rig. However I made the take off for checking the little gauge between the pump and valve. DOH! Not thinking clearly. I will sort that later this week.

The 1/4 BSP valve I had in the odds and ends box is not up to the job, it is leaking so I cannot maintain pressure. I will organise a replacement this week.

No boiler leaks, bone dry. YAY !

The 1/4 BSP valve I had in the odds and ends box is not up to the job, it is leaking so I cannot maintain pressure. I will organise a replacement this week.

No boiler leaks, bone dry. YAY !

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Re: Llewellyn Loco Works #1

It is always a good moment when something passes a test. Mind you having seen the photos of your soldering I think we all would have been surprised if it did leak.

Don

Don

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Thanks Don, I have a head start with Brass and Silver brazing, I have been involved with making steel bicycle frames for 40 years now.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

Why progress is slow on the little loco and the "Potters Orchid Railway" I around the 12.30 mark talking to engineering legend Peter Olds. I was fireman on 967 for the day. I had a drive with 8 on the hook the next day.

https://www.youtube.com/watch?v=v1O4DHw ... DxwQeklH9w

https://www.youtube.com/watch?v=v1O4DHw ... DxwQeklH9w

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Re: Llewellyn Loco Works #1

Nice video, like the locos.

Don

Don

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

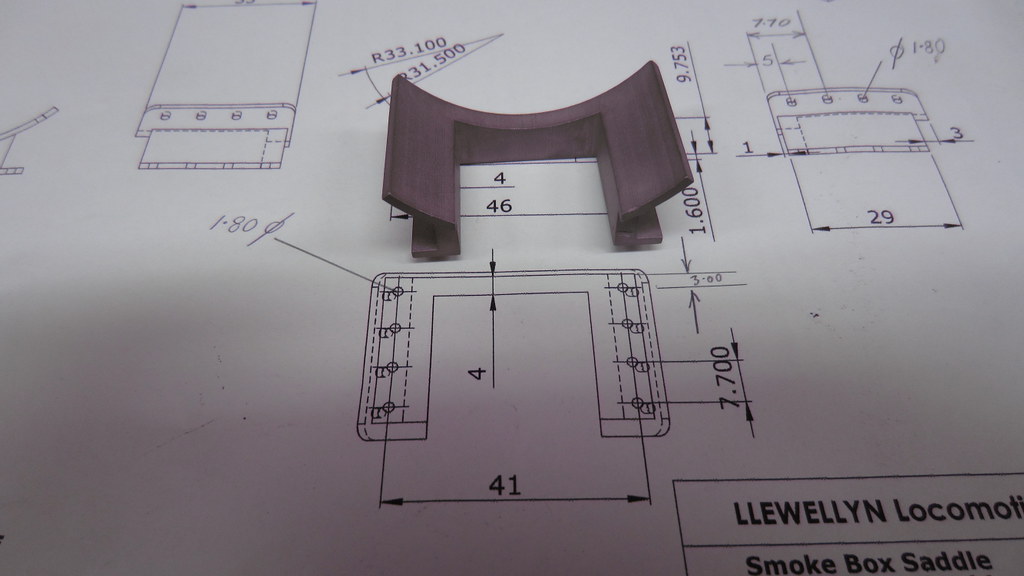

A simple job started, but it was nice to be in the Red Room last night with ABC jazz on the radio working on my little choo choo.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: Llewellyn Loco Works #1

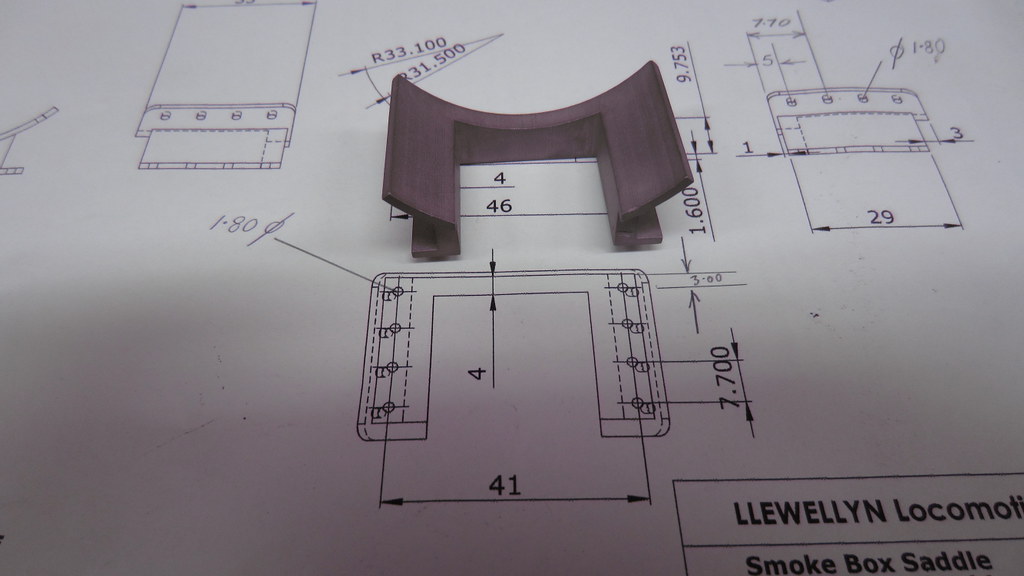

A little package arrived at the Llewellyn Locomotive Works from "Stannier Engineering" yesterday.

The workshop manager studies the smoke box saddle casting in his usual pensive manner as the head hand tries to get his head around it. Nice fella but dim at times.

Cast in White Bronze this new investment casting looks sweet.

The workshop manager studies the smoke box saddle casting in his usual pensive manner as the head hand tries to get his head around it. Nice fella but dim at times.

Cast in White Bronze this new investment casting looks sweet.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

Who is online

Users browsing this forum: No registered users and 15 guests