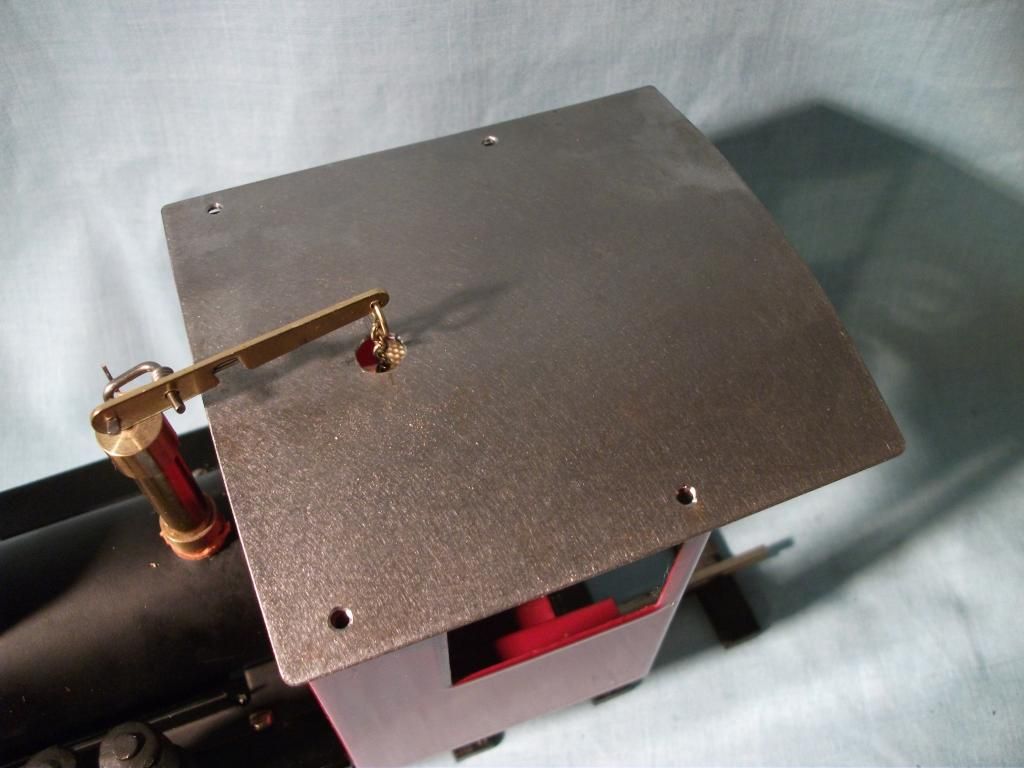

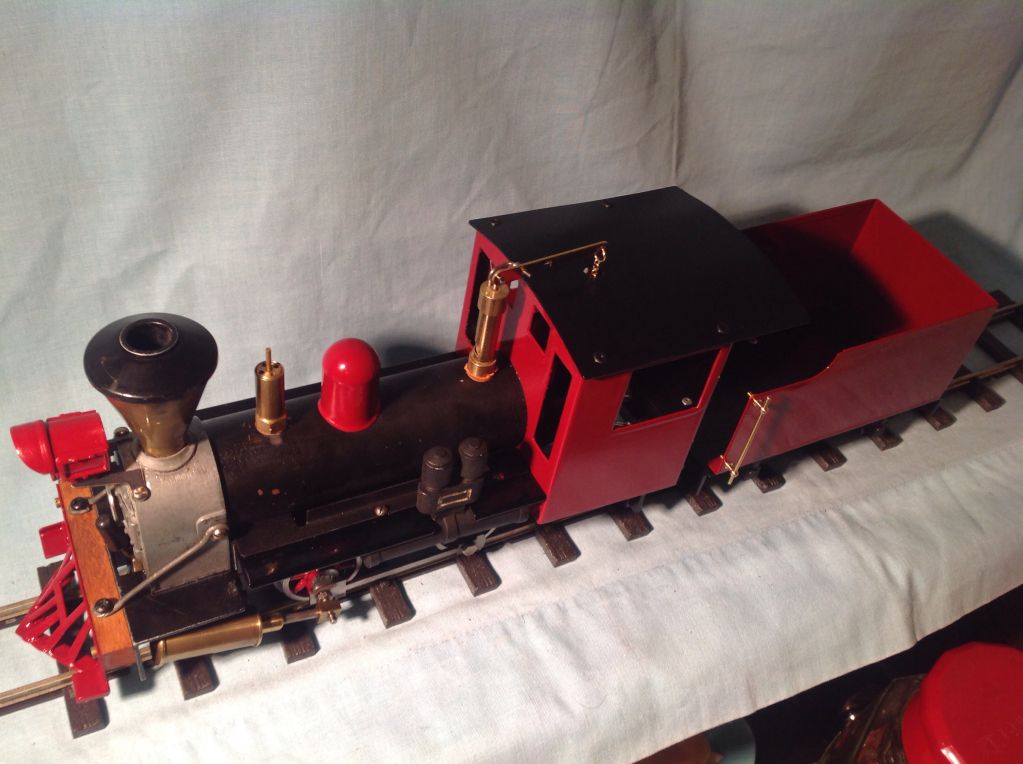

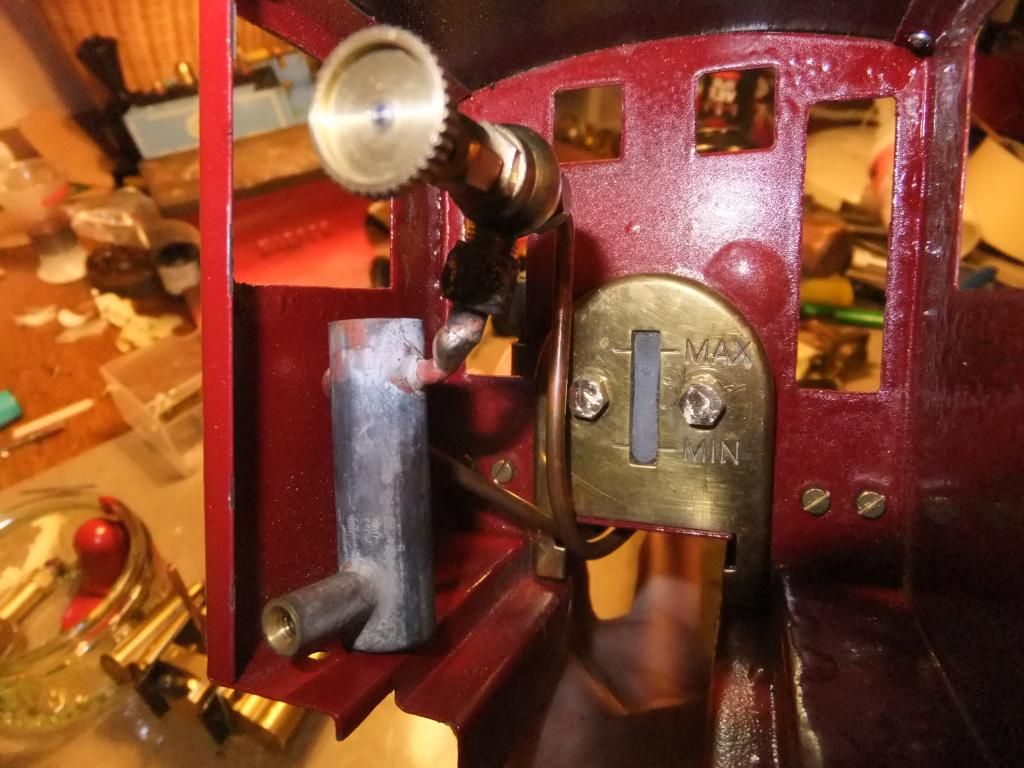

Chris, thanks for letting me know about Mamods attendance. I can now ask them face to face why they don't reply to my emails. As for a 40psi safety valve, I think that is a little much. This loco has a standard boiler that is silver soldered but it still has the standard sight glass. Ideally I'd like to get hold of a wilesco one or make a mamod upgraded 25 psi equivalent look like the wilesco with a bit of modification. I worry about the sight glasses blowing this one also has a gas burner so plenty of steam is made. I just ran it on rails for the first time 'light' and it seems ok. I'll pop some images up shortly.

Ready for the show I will be!

Having said that I will change it to get it to look how I want in time, just the essentials for now.