bambuko loco works 0-6-2 (Fowler)

- BorisSpencer

- Fireman

- Posts: 251

- Joined: Thu Apr 05, 2018 2:36 pm

- Location: East Northants

Re: bambuko loco works 0-6-2 (Fowler)

Just to add, the chassis I bought from Steve some time ago had blackened wheels, after a couple of test laps around the garden the tyres and flanges were shiny silver just as you would expect.

Also when I retreat the deck boards that form my track bed I don't worry about getting preservative on the rails, as after running a few train the top and inside of the rail head is back to bare metal, just as per prototype.

Also when I retreat the deck boards that form my track bed I don't worry about getting preservative on the rails, as after running a few train the top and inside of the rail head is back to bare metal, just as per prototype.

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Perfect

@ BorisSpencer - it's good to have confirmation of my theory

That what I was aiming for

@ BorisSpencer - it's good to have confirmation of my theory

That what I was aiming for

Re: bambuko loco works 0-6-2 (Fowler)

You mentioned "girls' first Chris....

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

That's beacuse I am an incorrigible dinosaur

ps I have been locting the wheels on axles since yesterday - not taking chances and leaving it for 24 hrs to set before touching, because it would be right PITA if something were to go wrong with it later...

Re: bambuko loco works 0-6-2 (Fowler)

........................

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- dewintondave

- Trainee Driver

- Posts: 697

- Joined: Mon Mar 07, 2011 8:52 am

- Location: New Zealand

Re: bambuko loco works 0-6-2 (Fowler)

Oil blackening steel is great. I've got some filthy lawnmower sump oil that puts a different finish on steel compared to clean oil. Thickness of the job and degree of heating before plunging into the oil makes a difference. I've been oil blackening screws most recently. I copped criticism from UK based H&S types, telling me the oil was carcinogenic

Best wishes,

Dave

Dave

Re: bambuko loco works 0-6-2 (Fowler)

Who cares what those H&S types think Dave. So long has you have what you need from doing the blackening is all that matters.....dewintondave wrote: ↑Fri Nov 15, 2019 4:43 am Oil blackening steel is great. I've got some filthy lawnmower sump oil that puts a different finish on steel compared to clean oil. Thickness of the job and degree of heating before plunging into the oil makes a difference. I've been oil blackening screws most recently. I copped criticism from UK based H&S types, telling me the oil was carcinogenic

By the way shows how intelligent I am..

When I was a young lad,

It's not happened yet....Now were is that piece of wood to touch.....

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Had a bit of a setback  with wheels loctited on the axles.

with wheels loctited on the axles.

The retention strength is nowhere near what it should be...

I don't know whether it is the age of my Loctite (I am using ancient 648 I had for years).

It shouldn't be, since I didn't have problems with it before, but just in case ordered another bottle of 638 (higher strength and tolerant of bigger gaps than 648).

It is possibly contamination caused by blackening?

Going to have to do some experiments and if necessary re-do the whole axle wheel thing

Trying not to get too depressed ...

The retention strength is nowhere near what it should be...

I don't know whether it is the age of my Loctite (I am using ancient 648 I had for years).

It shouldn't be, since I didn't have problems with it before, but just in case ordered another bottle of 638 (higher strength and tolerant of bigger gaps than 648).

It is possibly contamination caused by blackening?

Going to have to do some experiments and if necessary re-do the whole axle wheel thing

Trying not to get too depressed ...

Re: bambuko loco works 0-6-2 (Fowler)

Technically, the black coating is a thin porous layer of iron oxide, saturated with oil. As a chemist I'd classify it as a heavily contaminated surface for the purpose of making a joint with Loctite.bambuko wrote: ↑Sat Nov 16, 2019 10:20 am Had a bit of a setbackwith wheels loctited on the axles.

The retention strength is nowhere near what it should be...

I don't know whether it is the age of my Loctite (I am using ancient 648 I had for years).

It shouldn't be, since I didn't have problems with it before, but just in case ordered another bottle of 638 (higher strength and tolerant of bigger gaps than 648).

It is possibly contamination caused by blackening?

Going to have to do some experiments and if necessary re-do the whole axle wheel thing

Trying not to get too depressed ...

I doubt the age of the Loctite 648 is an issue. The bottle of Loctite 601 that I use for fitting wheels is over 30 years old and it still makes a joint that is hard to break, provided the surface is properly prepared.

Did you ream the bores of the wheels when you made them? If so, run the reamer through again which will scrape off the oxide, then degrease the bores with a suitable solvent and try the Loctite again.

If that doesn't work, there's less work involved if you just bore the holes in the wheels larger, press fit bushes and then ream for the existing axles.

Regards,

Graeme

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

thank you GBT,

that was my (reluctant) conclusion as well

as they say in the trade "cluster f**k up" on my part

mine is also over 30 years old

I finished with reaming, but I will try to get everything properly cleaned (and use 638 which can cope with bigger gaps)

Can be done this way, but it is probably six ve half a dozen (or whatever is the correct English idiom

- dewintondave

- Trainee Driver

- Posts: 697

- Joined: Mon Mar 07, 2011 8:52 am

- Location: New Zealand

Re: bambuko loco works 0-6-2 (Fowler)

So true Rod. There's a lot of scaredy cats out there. I love burnt toast too! Everything is carcinogenic, just some things more than othersFWLR wrote: ↑Sat Nov 16, 2019 7:02 am

Who cares what those H&S types think Dave. So long has you have what you need from doing the blackening is all that matters.....

By the way shows how intelligent I am..I didn't have a clue what carcinogenic meant until I looked it up...

{Things that could cause cancer.}

When I was a young lad,I was told, if you eat burnt toast you will get cancer....

It's not happened yet....Now were is that piece of wood to touch.....

Best wishes,

Dave

Dave

Re: bambuko loco works 0-6-2 (Fowler)

"Six of one and half a dozen of the other" ....... Dave...

ROD

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

Life is so easy when I run my trains.

https://gardenrails.org/forum/viewtopic ... 41&t=11364

https://www.youtube.com/@fairywoodlightrailway

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Thank you FWLR

It's just lazy of me - should have googled it before posting

before posting

It's just lazy of me - should have googled it

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Sounds like I got away with it

Cleaned axle holes in the wheels with wet & dry, soaked the wheels in acetone for two days, put them in a dishwasher

and after preparing them as normal loctited using Loctite 638.

Job done - they are solid

Next is the rear trailing pony truck, to finish all the wheels.

The only minor complication is that I want to use ceramic burner rather than poker burner,

so I will have to make sure that it not only fits in the frames but also fits around pony truck.

I think this will call for a mock up rather than just trying to design it on CAD...

Cleaned axle holes in the wheels with wet & dry, soaked the wheels in acetone for two days, put them in a dishwasher

and after preparing them as normal loctited using Loctite 638.

Job done - they are solid

Next is the rear trailing pony truck, to finish all the wheels.

The only minor complication is that I want to use ceramic burner rather than poker burner,

so I will have to make sure that it not only fits in the frames but also fits around pony truck.

I think this will call for a mock up rather than just trying to design it on CAD...

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

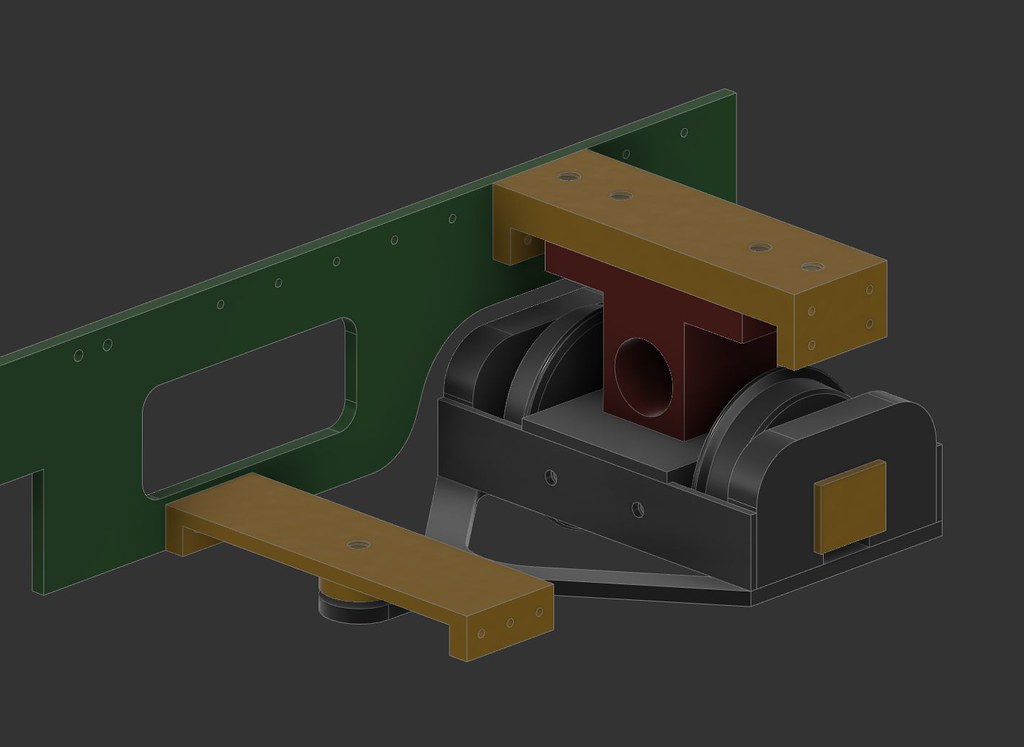

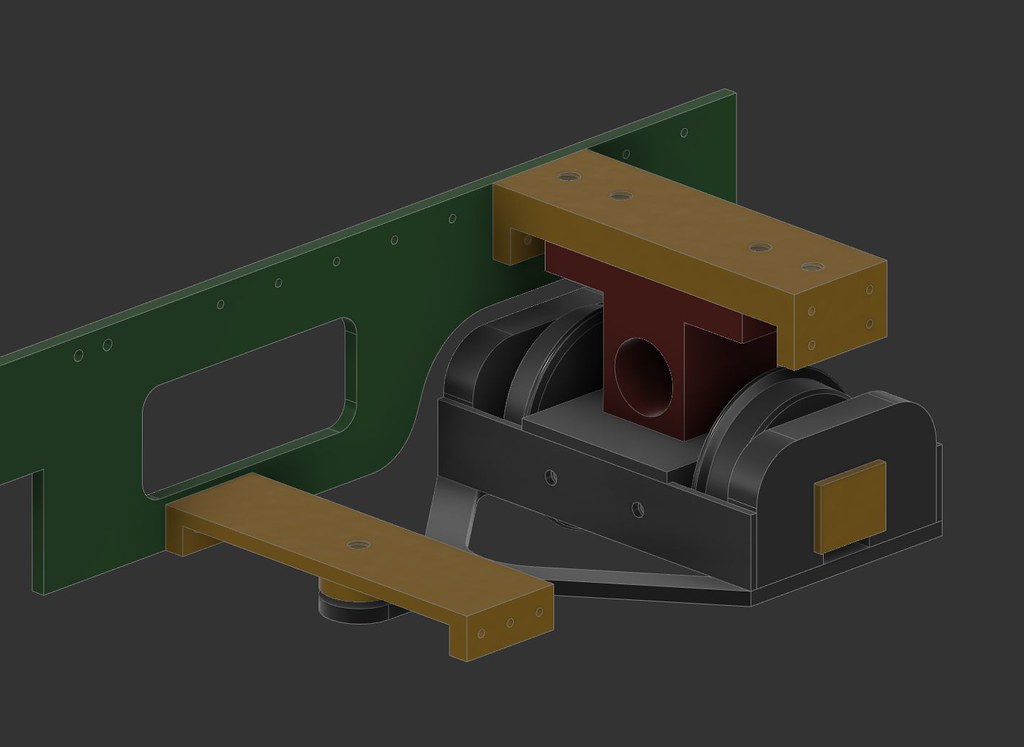

Spent couple of days pondering how to fit the burner and pony truck in the space available and here is what I came up with:

It's shown with LH frame removed for clarity.

Red block secured with two bolts to frame stretcher is both burner bracket and provides bearing surface for pony truck to slide sideways.

Red block is shown with 10mm hole for gas burner, but it could also be changed to meth burner if I find problems with ceramic burner.

Of course meth or ceramic gas burner can be dispensed with and replaced with gas poker above, in which case red block becomes only a bearing surface for pony truck.

Weight of the pony truck and it's freedom to move up and down (a bit) as well as left and right, should be sufficient to keep pony wheels in contact with rails, but...

if necessary I guess it should be easy to add some springing.

Methinks it's time to start cutting metal

It's shown with LH frame removed for clarity.

Red block secured with two bolts to frame stretcher is both burner bracket and provides bearing surface for pony truck to slide sideways.

Red block is shown with 10mm hole for gas burner, but it could also be changed to meth burner if I find problems with ceramic burner.

Of course meth or ceramic gas burner can be dispensed with and replaced with gas poker above, in which case red block becomes only a bearing surface for pony truck.

Weight of the pony truck and it's freedom to move up and down (a bit) as well as left and right, should be sufficient to keep pony wheels in contact with rails, but...

if necessary I guess it should be easy to add some springing.

Methinks it's time to start cutting metal

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: bambuko loco works 0-6-2 (Fowler)

You are doing such a nice job, put a grate in and burn the black stuff.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Thank you.Hydrostatic Dazza wrote: ↑Thu Dec 05, 2019 7:31 pm You are doing such a nice job, put a grate in and burn the black stuff.

I would like to do it indeed

Plus, adding axle pump at this stage would be a bit of PITA

I will leave it for the next one

Having said so - this mod is not impossible and the way this project is meandering you never know where it might end up

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

Something slightly different (i.e. no update, although I am making progress  )

)

Here is one of the original, Leeds build Aussie Fowlers that made it's way back to UK:

She is in "Steam Workshop":

https://www.steamworkshop.co.uk/portfol ... ler-16341/

and here as she was in Australia:

http://www.australiansteam.com/fowler16341.htm

and more photos:

http://www.steamworkshop.co.uk/portfoli ... s-fowlers/

Shame I got the vids and photos only now and not when I was designing my model (which suffered from desperate shortage of decent photos of original)

OK, she is 0-4-2 not 0-6-2 (which I am building) but other than that she is much of the muchness...

Not surprising since someone like Fowler wouldn't be re-inventing the wheel every time it build a locomotive

Lot of common components and familiar design aspects.

Hope you guys enjoy it as well

Here is one of the original, Leeds build Aussie Fowlers that made it's way back to UK:

She is in "Steam Workshop":

https://www.steamworkshop.co.uk/portfol ... ler-16341/

and here as she was in Australia:

http://www.australiansteam.com/fowler16341.htm

and more photos:

http://www.steamworkshop.co.uk/portfoli ... s-fowlers/

Shame I got the vids and photos only now and not when I was designing my model (which suffered from desperate shortage of decent photos of original)

OK, she is 0-4-2 not 0-6-2 (which I am building) but other than that she is much of the muchness...

Not surprising since someone like Fowler wouldn't be re-inventing the wheel every time it build a locomotive

Lot of common components and familiar design aspects.

Hope you guys enjoy it as well

- Hydrostatic Dazza

- Driver

- Posts: 1167

- Joined: Tue Sep 19, 2017 4:17 am

- Location: Brisbane

- Contact:

Re: bambuko loco works 0-6-2 (Fowler)

There were articles in AME magazine in 2017, they did thermal modeling of what happens in a coal fired wet leg boiler when run dry. The temperature rise was very little and well within the brazing and copper material stability, due to the draft on the fire ceasing as soon as the water was gone. thus in the small garden size grates, the fire dies to a ember. (if you use soft solder well ??) They backed this up with actual testing and measuring temperatures and all was very close to the thermal modeling. I saw this in action on the loco at my local ME club run. They have a small garden track there now. I know many will bebambuko wrote: ↑Thu Dec 05, 2019 8:35 pmThank you.Hydrostatic Dazza wrote: ↑Thu Dec 05, 2019 7:31 pm You are doing such a nice job, put a grate in and burn the black stuff.

I would like to do it indeedbut this particular model would need too much butchery to rear of the cab to permit easy access for the shovel.

Plus, adding axle pump at this stage would be a bit of PITA

I will leave it for the next one

Having said so - this mod is not impossible and the way this project is meandering you never know where it might end up

Last edited by Hydrostatic Dazza on Thu Apr 16, 2020 11:08 pm, edited 1 time in total.

Cheers from Dazza, The Hydrostatic Lubricator

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

The chances of finding out what’s really going on in the universe are so remote, the only thing to do is hang the sense of it and keep yourself occupied. Douglas Adams

- bambuko

- Trainee Fireman

- Posts: 212

- Joined: Tue Dec 12, 2017 12:11 am

- Location: UK, England, North Devon

Re: bambuko loco works 0-6-2 (Fowler)

How does it square with the boiler code which requires you to have two independent sources of feedwater (regardless of boiler size)?Hydrostatic Dazza wrote: ↑Wed Dec 11, 2019 8:46 pm ...There were articles in AME magazine in 2017, they did thermal modeling of what happens in a coal fired wet leg boiler when run dry ...I saw this in action on the loco at my local ME club run...

I am not saying that the article was wrong, simply asking how can you run (in a club environment) something that does not adhere to the code?

What you run in your private back garden is your own business, but in public... it's another story?

YesHydrostatic Dazza wrote: ↑Wed Dec 11, 2019 8:46 pm ...I know many will bewith the concept of a coal fired garden steamer without a pump...

Yes, you have - thank you very much!Hydrostatic Dazza wrote: ↑Wed Dec 11, 2019 8:46 pm ... Did I email the scans of these AME articles to you ?

I personally dislike axle feed pumps in smaller scales, so these articles are very encouraging

Who is online

Users browsing this forum: No registered users and 4 guests