Page 26 of 46

Re: Llewellyn Loco Works #1

Posted: Wed Nov 13, 2019 7:53 pm

by Tom the blacksmith

tom_tom_go wrote: ↑Tue Nov 12, 2019 11:15 pm

Perfection, a shame to paint it!

Couldn't agree with you more Tom, spot on Dazza!

Looking forward to whatever is next,

Best,

Tom

Re: Llewellyn Loco Works #1

Posted: Wed Nov 13, 2019 10:50 pm

by Hydrostatic Dazza

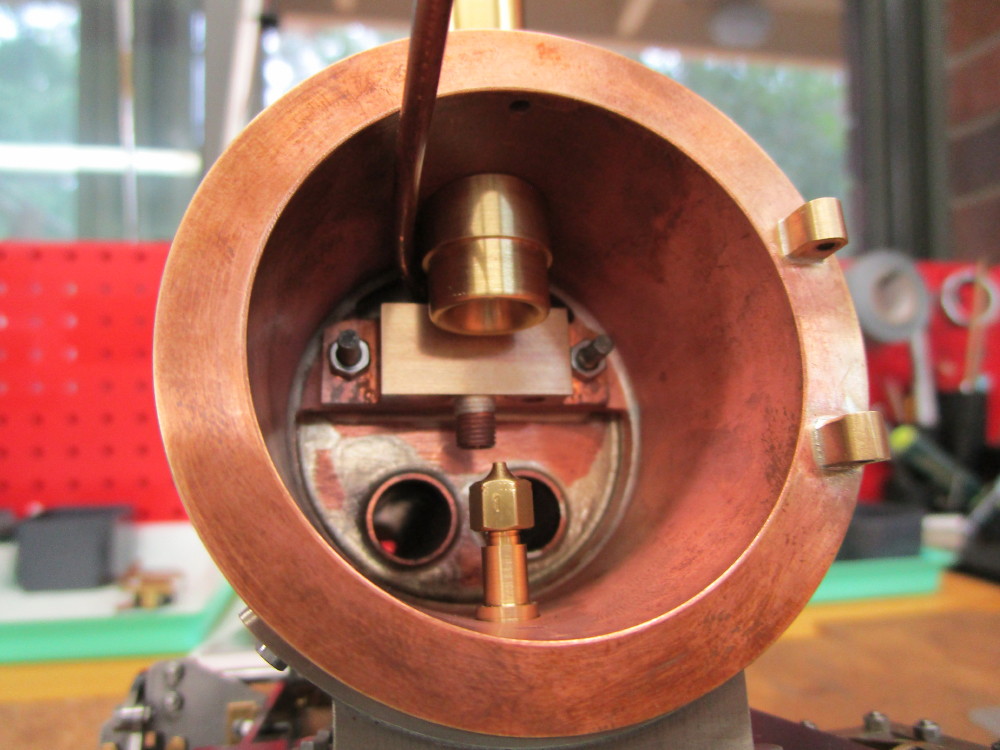

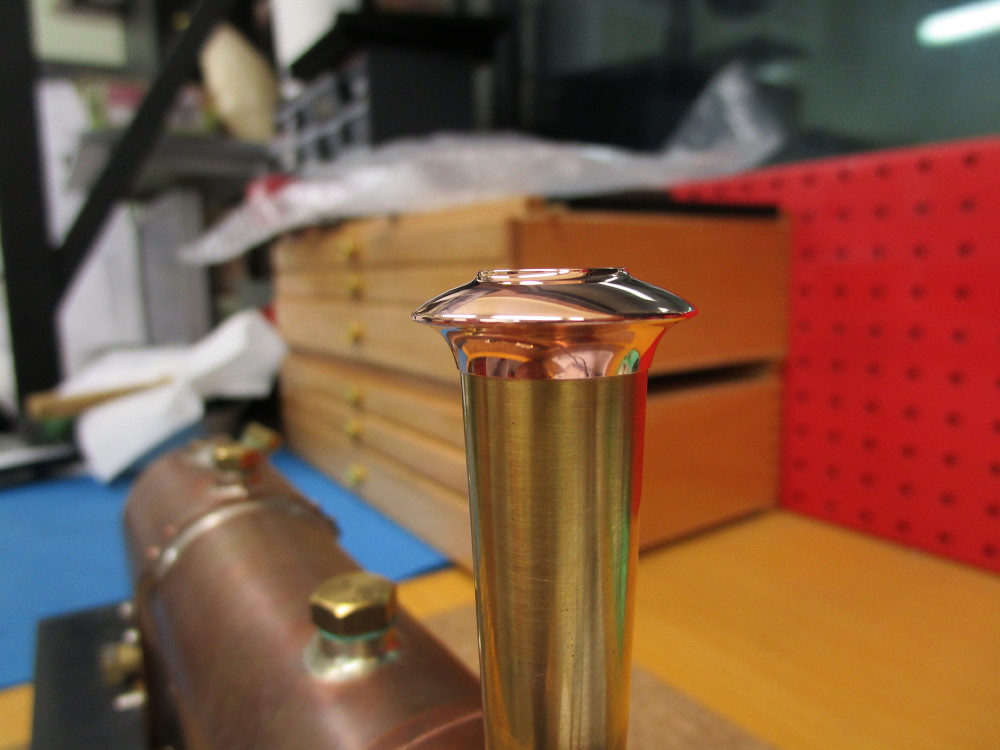

Blast pipe last night.

Re: Llewellyn Loco Works #1

Posted: Fri Nov 15, 2019 12:46 pm

by DonW

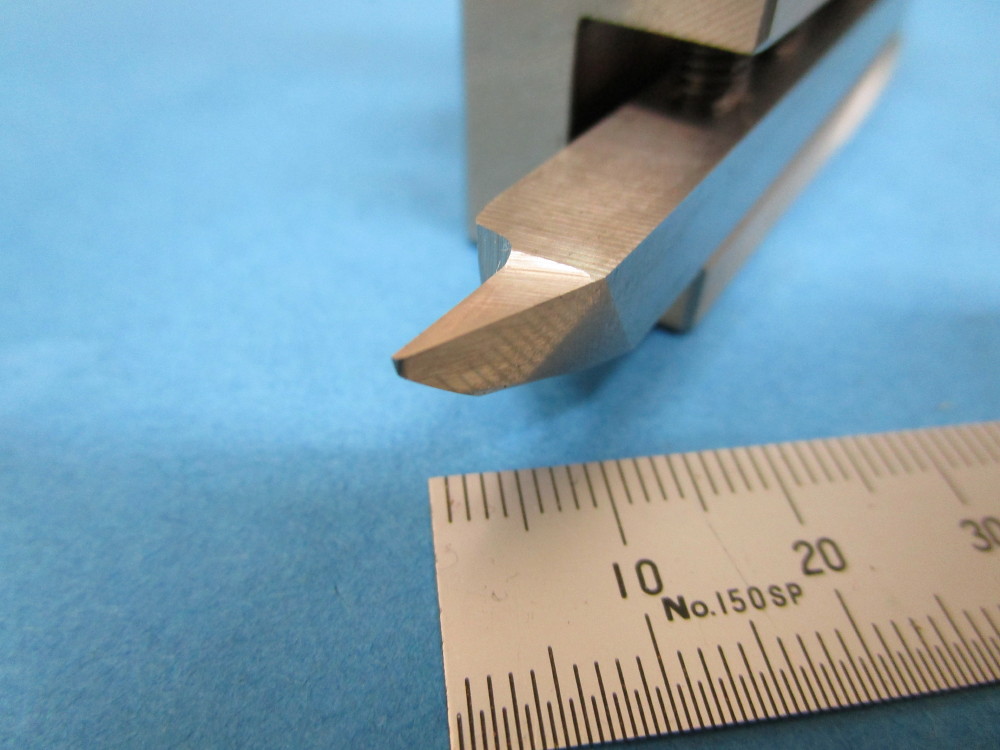

More top quality work Dazza. The Turnado system I understand to be using hand held tools which I know more as Graving. The people I know who use Graving are the 2mm finescale workers where they are making very fine cuts most of the time.

Don

Re: Llewellyn Loco Works #1

Posted: Mon Nov 18, 2019 9:25 pm

by Hydrostatic Dazza

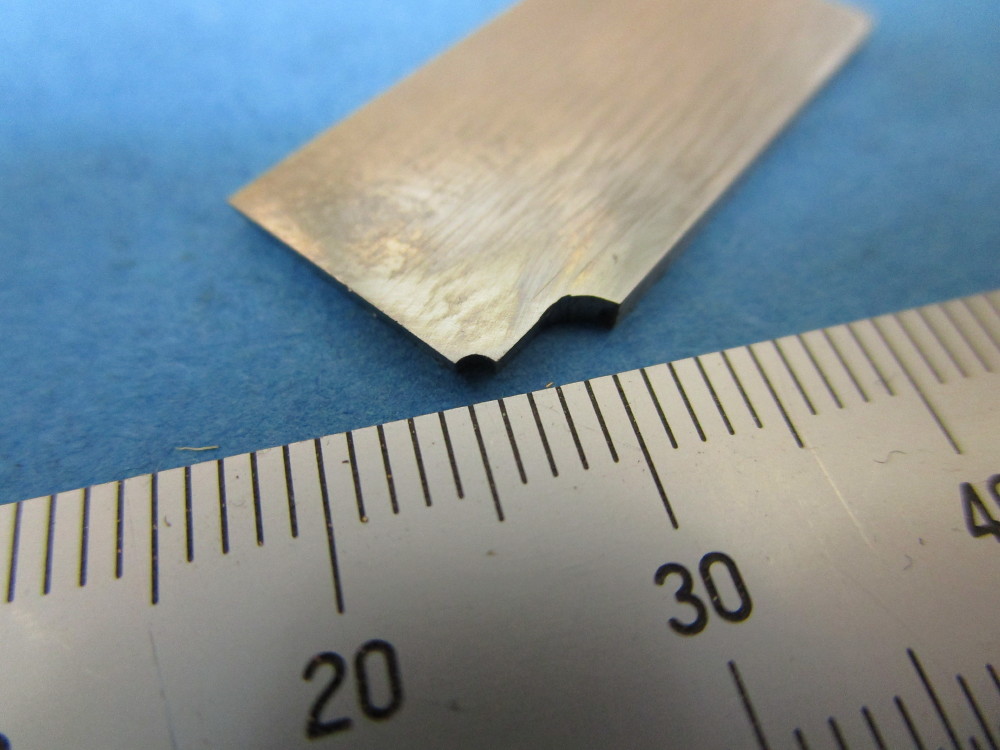

Last night was proof of concept. I was pleased it worked. I made a second one to ensure it was not a fluke. I will make the rest of them soon and alter the settings to get a flatter dome.

Re: Llewellyn Loco Works #1

Posted: Mon Nov 18, 2019 9:29 pm

by bambuko

When you say 1.6mm dia rivet, do you mean stem dia or head dia?

Impressive, regardless of which

Re: Llewellyn Loco Works #1

Posted: Tue Nov 19, 2019 2:13 am

by Hydrostatic Dazza

bambuko wrote: ↑Mon Nov 18, 2019 9:29 pm

When you say 1.6mm dia rivet, do you mean stem dia or head dia?

Impressive, regardless of which

1.60mm diameter head

1.00mm diameter shank.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 19, 2019 8:04 pm

by Hydrostatic Dazza

Squeeze the tweezers too hard and "Ping" , two were teleported to another time and dimension last night. One was ruined, too tight a fit. But the last one was made in 15 mins, I am getting across the process and feel. 5 to go. I use a sharp centre pop to make them a press fit. The hinges will be silver brazed into the door. It is fun. Not some thing I want to do every week and I will be sated when these are done.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 19, 2019 8:22 pm

by tom_tom_go

Looking forward to you starting your 5" gauge loco given the standards you set yourself.

Re: Llewellyn Loco Works #1

Posted: Mon Dec 02, 2019 8:31 am

by pandsrowe

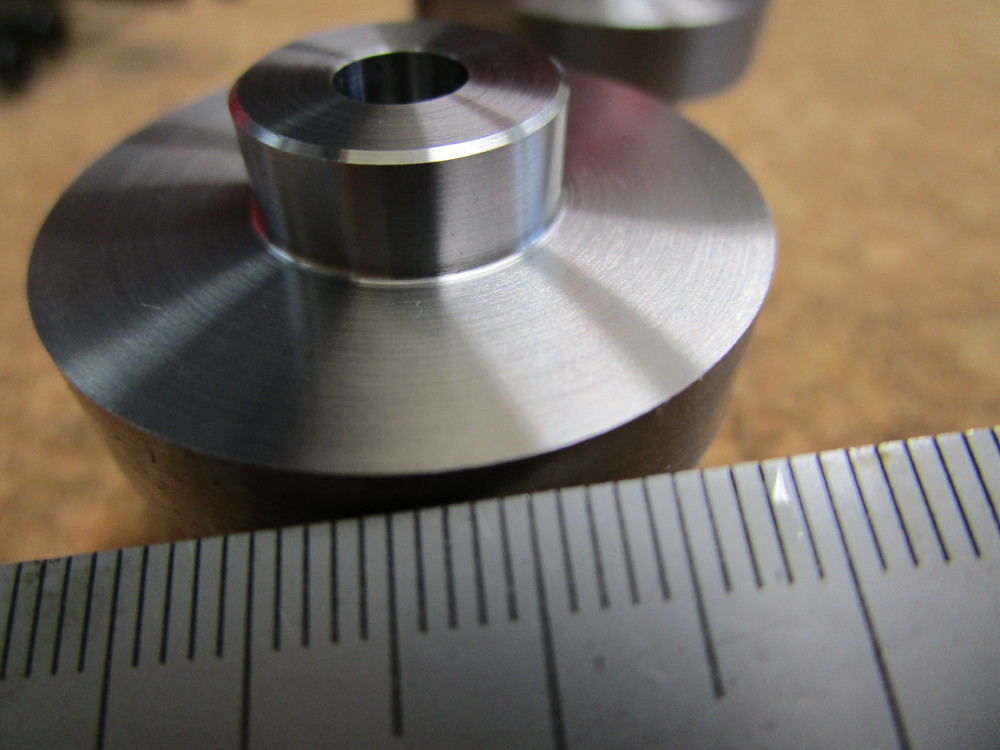

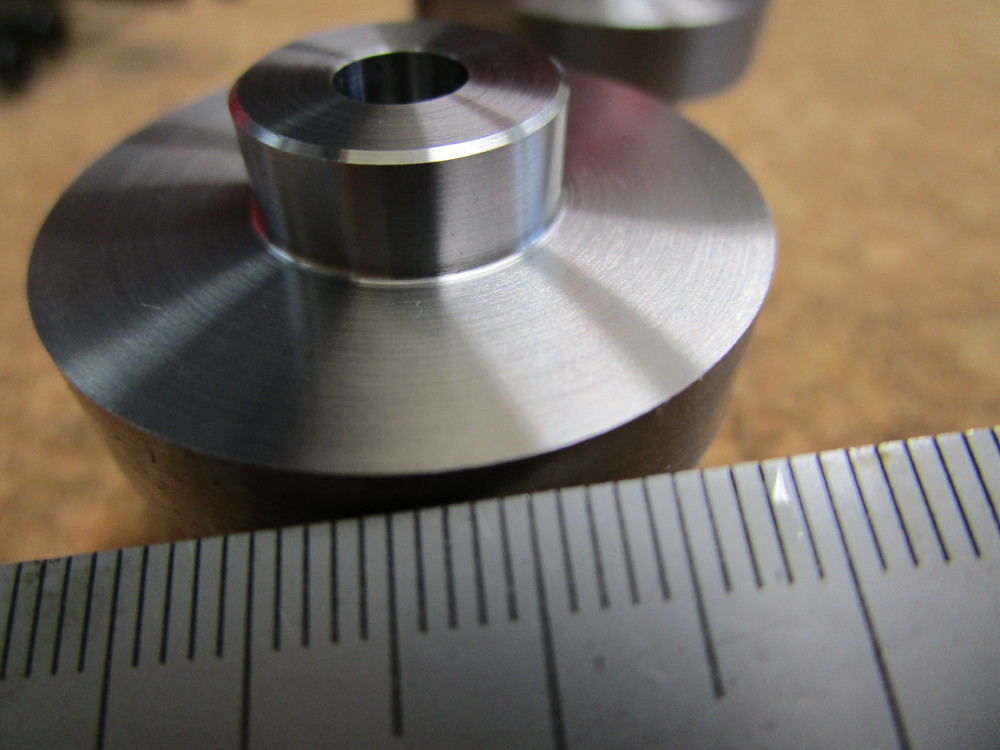

A superb piece of turning work, you should be very pleased with yourself Dazza.

One thing puzzles me, what is the purpose (if any) of the O ring on the parent stock?

Re: Llewellyn Loco Works #1

Posted: Mon Dec 02, 2019 7:44 pm

by Hydrostatic Dazza

pandsrowe wrote: ↑Mon Dec 02, 2019 8:31 am

A superb piece of turning work, you should be very pleased with yourself Dazza.

One thing puzzles me, what is the purpose (if any) of the O ring on the parent stock?

Thanks and I was wondering if some one would notice and ask.

It works like a little dam wall , it stops the coolant flowing towards the chuck and then being flung off. Keeps me and the surrounds a wee bit more "coolant free"

I lay claim that I conceived the idea all on my own.

The Turnado tool is used dry

Re: Llewellyn Loco Works #1

Posted: Sat Feb 22, 2020 8:34 pm

by Hydrostatic Dazza

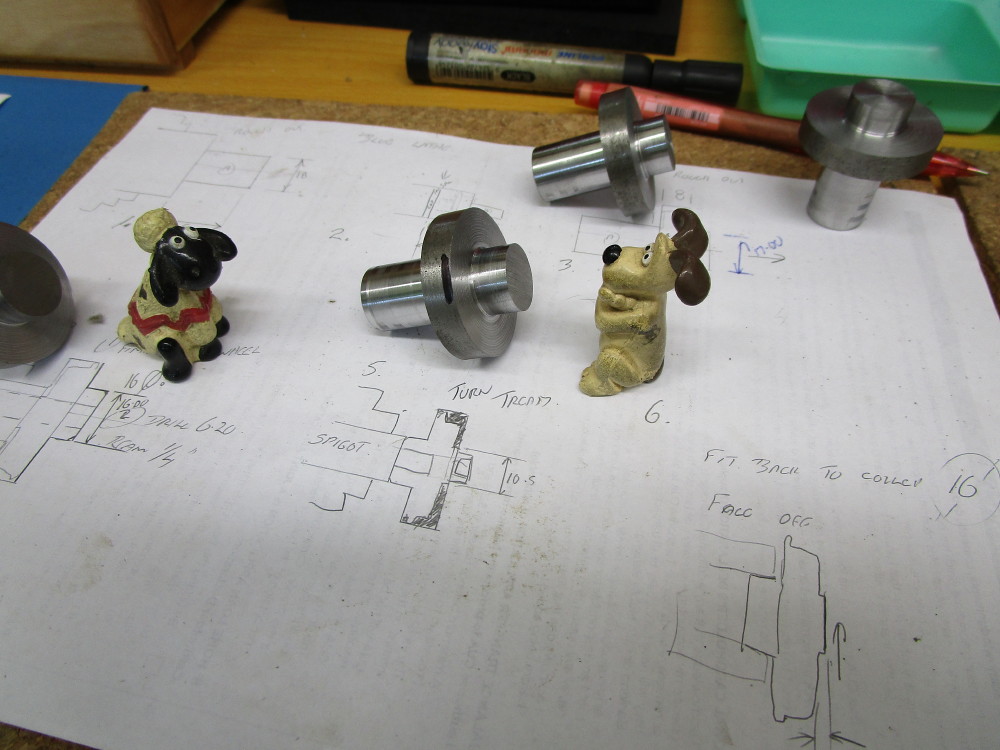

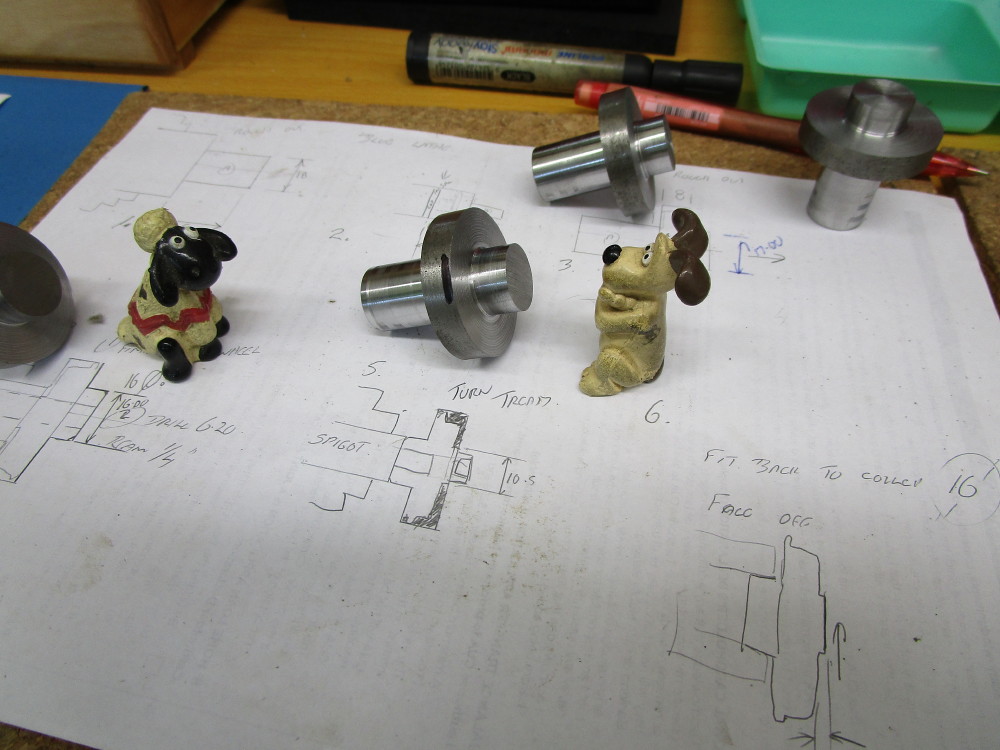

"I say Gromit, this all looks straight forward, the same process as the drivers. Get Feathers and Preston to rough the blanks out. "

Re: Llewellyn Loco Works #1

Posted: Sat Feb 22, 2020 8:34 pm

by Hydrostatic Dazza

Whrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr

Re: Llewellyn Loco Works #1

Posted: Sat Feb 22, 2020 8:38 pm

by Hydrostatic Dazza

"These look OK, Shaun, take them to the Myford and finish off the backs and ream please."

Re: Llewellyn Loco Works #1

Posted: Sat Feb 22, 2020 8:39 pm

by Hydrostatic Dazza

Tread profile is next.

Re: Llewellyn Loco Works #1

Posted: Sat Feb 22, 2020 8:40 pm

by tom_tom_go

Are these wheels for the loco or tender?

Re: Llewellyn Loco Works #1

Posted: Sun Feb 23, 2020 8:40 pm

by Hydrostatic Dazza

tom_tom_go wrote: ↑Sat Feb 22, 2020 8:40 pm

Are these wheels for the loco or tender?

These are the tender wheels. The Loco has is drivers, it all goes around on air, boiler in the frames etc, but the trialing pony wheel set is yet to be done.

Re: Llewellyn Loco Works #1

Posted: Sun Feb 23, 2020 8:44 pm

by tom_tom_go

I think you mentioned a while back you will be installing a SSP Slomo in the tender?

Terry recommends using ball bearings on the axles of wagons or tenders fitted with a Slomo, info below:

http://smallsteamperformance.com.au/kit ... or-wagons/

He is a top bloke, I have been very happy with the units I have purchased from him.