Page 25 of 46

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 8:33 am

by FWLR

I do love seeing your progress Dazza. That door is looking great.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 9:09 am

by bambuko

Hydrostatic Dazza wrote: ↑Mon Nov 04, 2019 8:29 pm

...so far using my hand wheel feed on the mill/drill and the DRO on the quill Z I am yet to break one. But crikey I go at a 0.10 -0.15 mm per second with the feed....Never a drill chuck. I never use a drill chuck with any drills in the mill/drill.

I couldn't possibly use direct feed on my Bridgeport for such small drills.

I use micro drill adapter:

http://www.penntoolco.com/llambrichusa- ... -adapters/

Unfortunately my budget doesn't extend to $600 for such a thing, so I have Chinese knock-off

You get what you pay.... hence my experience

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 11:14 am

by pandsrowe

Not intended as a criticism, but presumably the smoke box will be painted so why not brass rivets? Certainly a lot easier to obtain and to rivet into place.

On reflection, having been following this thread for some time I am beginning to feel that you are perhaps a little masochistic and want to do things the hard way, whichever you are still doing a fantastic job on this loco.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 11:57 am

by bambuko

Your "masochistic" is somebody else's "attention to detail"

No, I wouldn't use stainless either, but it is Dazza's railway

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 8:43 pm

by Hydrostatic Dazza

bambuko wrote: ↑Tue Nov 05, 2019 9:09 am

Hydrostatic Dazza wrote: ↑Mon Nov 04, 2019 8:29 pm

...so far using my hand wheel feed on the mill/drill and the DRO on the quill Z I am yet to break one. But crikey I go at a 0.10 -0.15 mm per second with the feed....Never a drill chuck. I never use a drill chuck with any drills in the mill/drill.

I couldn't possibly use direct feed on my Bridgeport for such small drills.

I use micro drill adapter:

http://www.penntoolco.com/llambrichusa- ... -adapters/

Unfortunately my budget doesn't extend to $600 for such a thing, so I have Chinese knock-off

You get what you pay.... hence my experience

I just use the fine feed hand wheel , worm thing. I rigged up a $50 digital DRO on the quill so I can good understanding of the depth and feed rates etc etc.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 8:51 pm

by Hydrostatic Dazza

pandsrowe wrote: ↑Tue Nov 05, 2019 11:14 am

Not intended as a criticism, but presumably the smoke box will be painted so why not brass rivets? Certainly a lot easier to obtain and to rivet into place.

On reflection, having been following this thread for some time I am beginning to feel that you are perhaps a little masochistic and want to do things the hard way, whichever you are still doing a fantastic job on this loco.

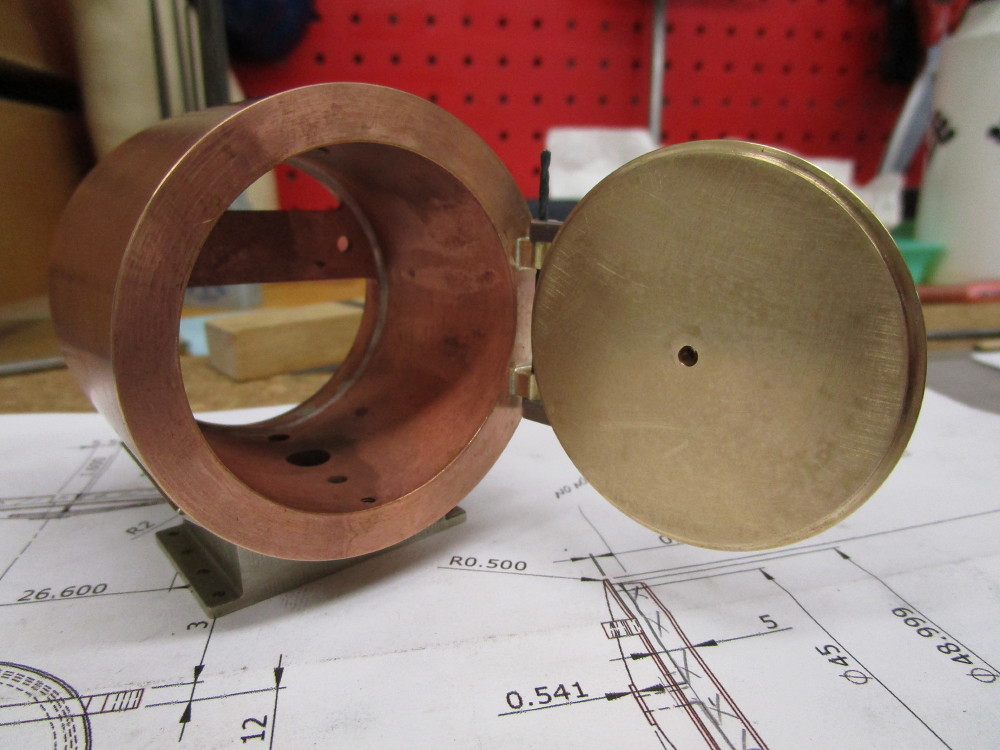

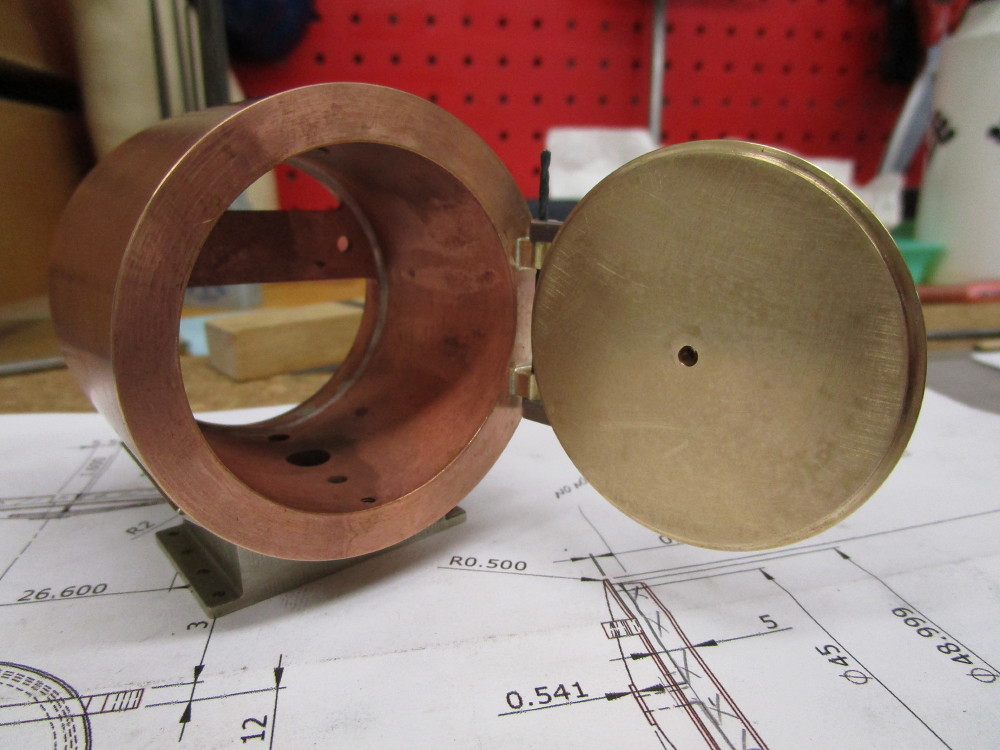

It is not about doing things the hard way as I am emulating the smoke doors on some Talyllyn, Welshpool & Llanfair and the tank locos of the Vale of Rheidole locos where the straps are bare steel. The door will be painted but not the hinges, so I used stainless to keep it all neat. One aspect I spoke of earlier in this thread that this build project is a skill and knowledge acquisition process towards my Magnum Opus build which will be another 5" gauge loco.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 05, 2019 9:21 pm

by Hydrostatic Dazza

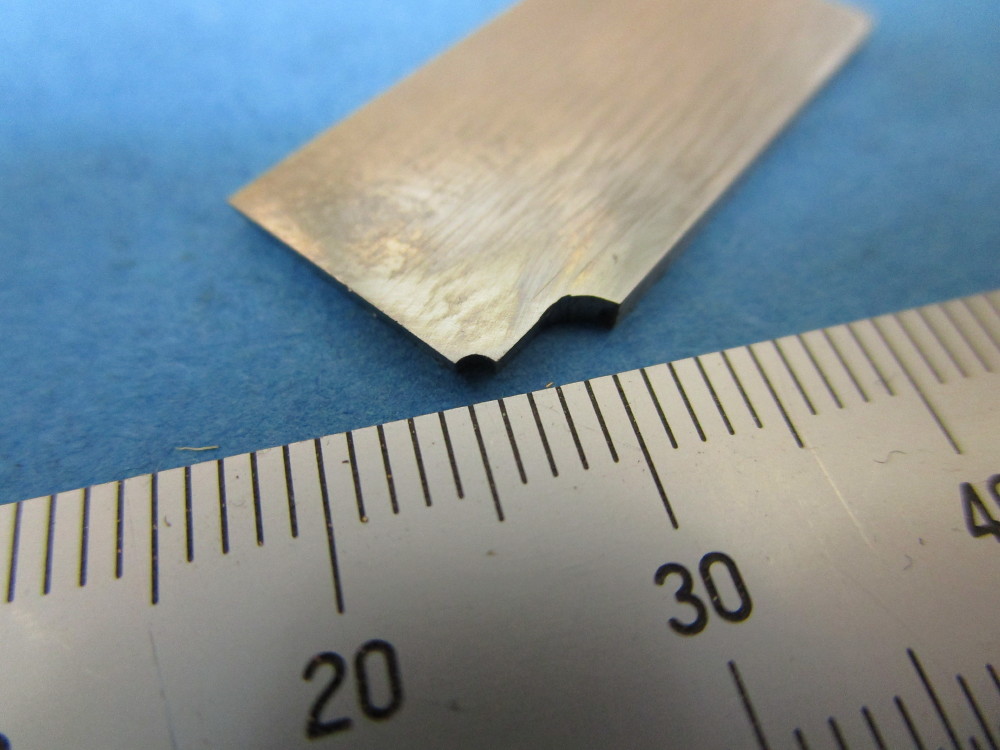

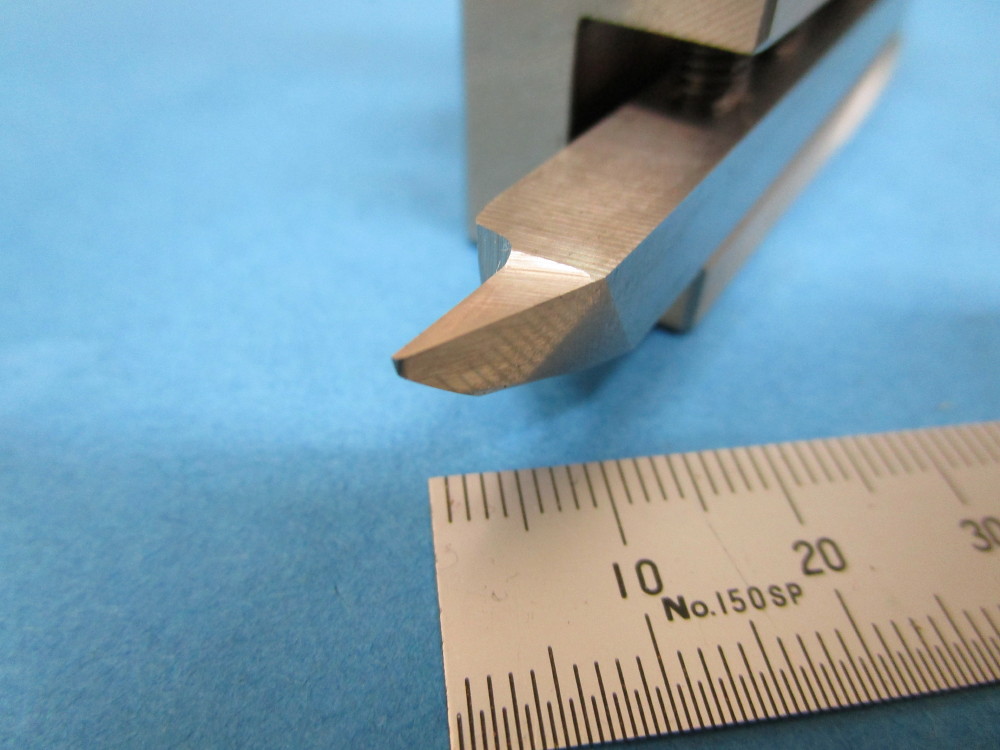

Also, I used a free machining grade of stainless steel, not 316 or such like, bought for a few dollars via ebay. It is not not at all difficult to use. I tried drilling 1.00mm holes with Sutton twist drills, they did not do well, so I just got out the Carbide PCB drills, dirt cheap via ebay and all went sweet. Slow steady feed with no jerks and all is sweet.

The pic is 0.50mm hole being drilled in the silicon bronze expansion link supports for kicks and giggles oil hole, the same can be done in stainless, even 316 or gauge plate. These drills make dust, not twirls of jamming swarf and being carbide they are brittle but do not blunt readily.

Re: Llewellyn Loco Works #1

Posted: Thu Nov 07, 2019 9:04 pm

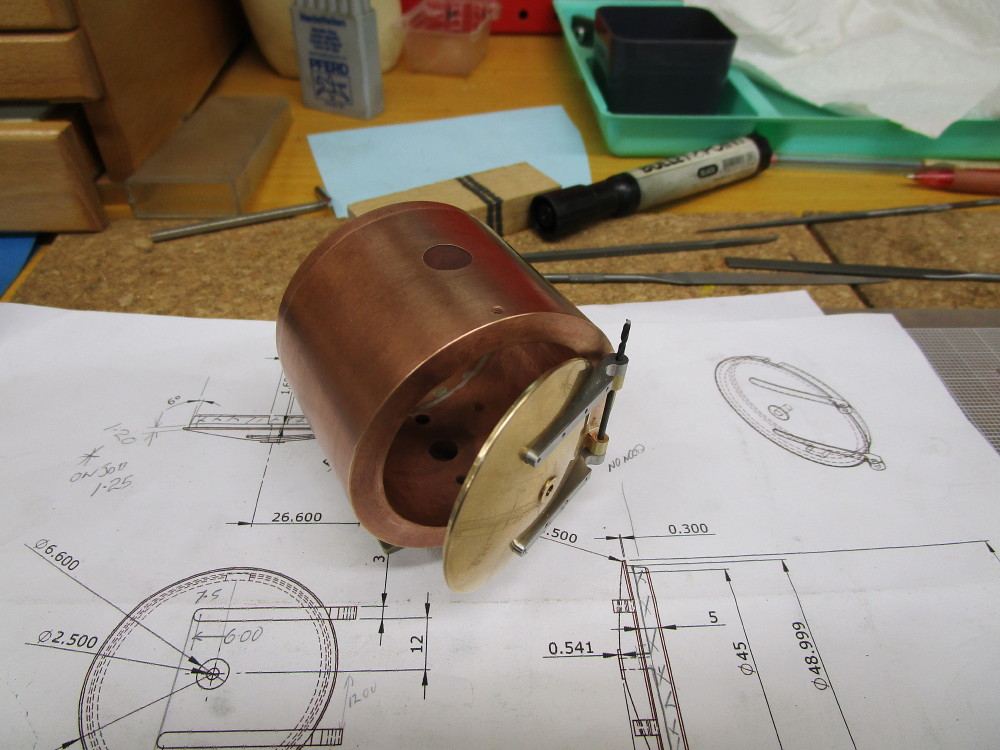

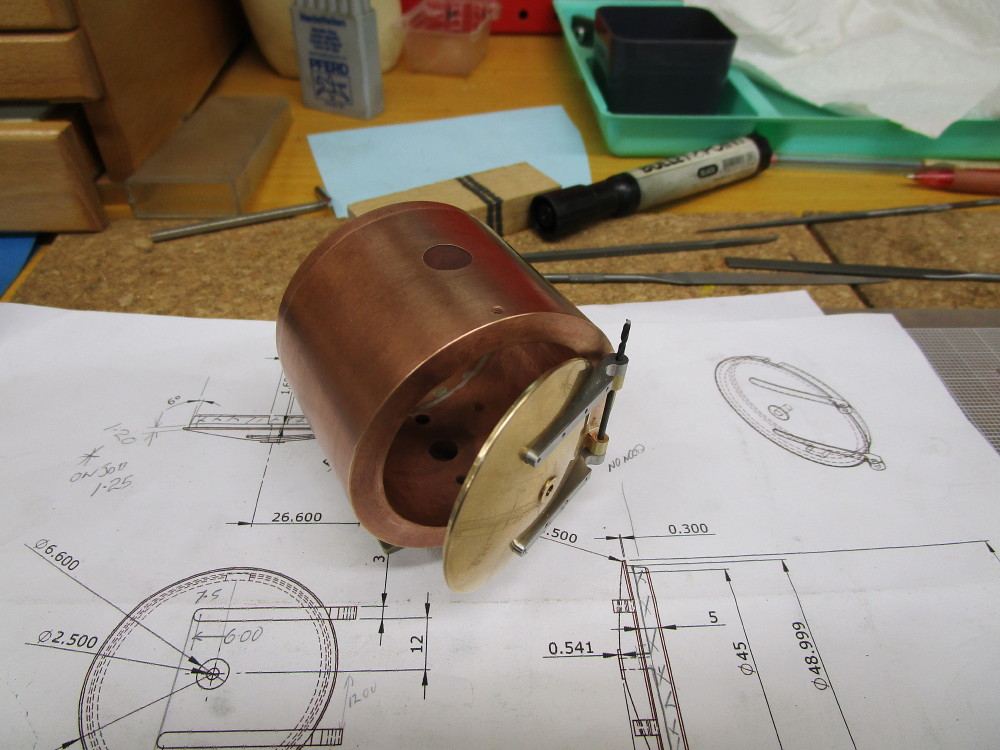

by Hydrostatic Dazza

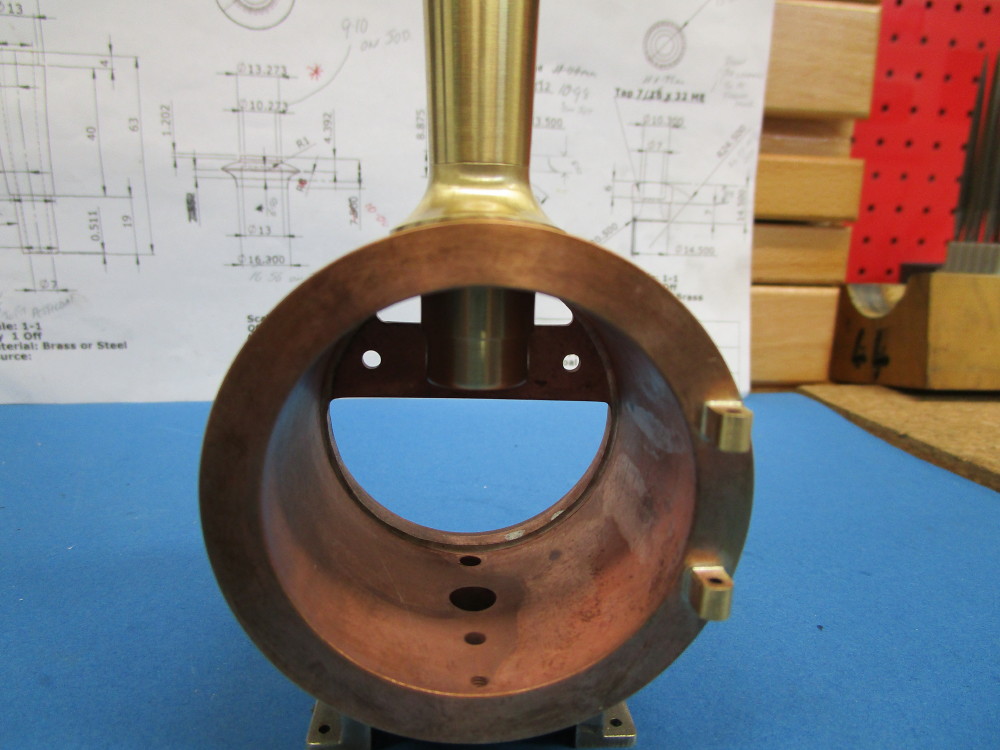

I got a cheap little Rotary table some time ago and never used it, till last night when it was just the ticket to get the 24.55mm radius on the upper part of the petticoat.

Re: Llewellyn Loco Works #1

Posted: Mon Nov 11, 2019 8:39 pm

by Hydrostatic Dazza

1" Brass, a wee spin in the Myford. The Turnado turning system put the radius on the Chimney base piece.

Then one hour with the files and grits while ABC jazz was on the radio has one side blended in.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 12, 2019 11:33 am

by tom_tom_go

Nicely done, I need to do the same on my 5" loco as the chimney base is not finished off evenly on all sides.

Re: Llewellyn Loco Works #1

Posted: Tue Nov 12, 2019 11:15 pm

by tom_tom_go

Perfection, a shame to paint it!

Re: Llewellyn Loco Works #1

Posted: Wed Nov 13, 2019 7:53 pm

by Tom the blacksmith

tom_tom_go wrote: ↑Tue Nov 12, 2019 11:15 pm

Perfection, a shame to paint it!

Couldn't agree with you more Tom, spot on Dazza!

Looking forward to whatever is next,

Best,

Tom

Re: Llewellyn Loco Works #1

Posted: Wed Nov 13, 2019 10:50 pm

by Hydrostatic Dazza

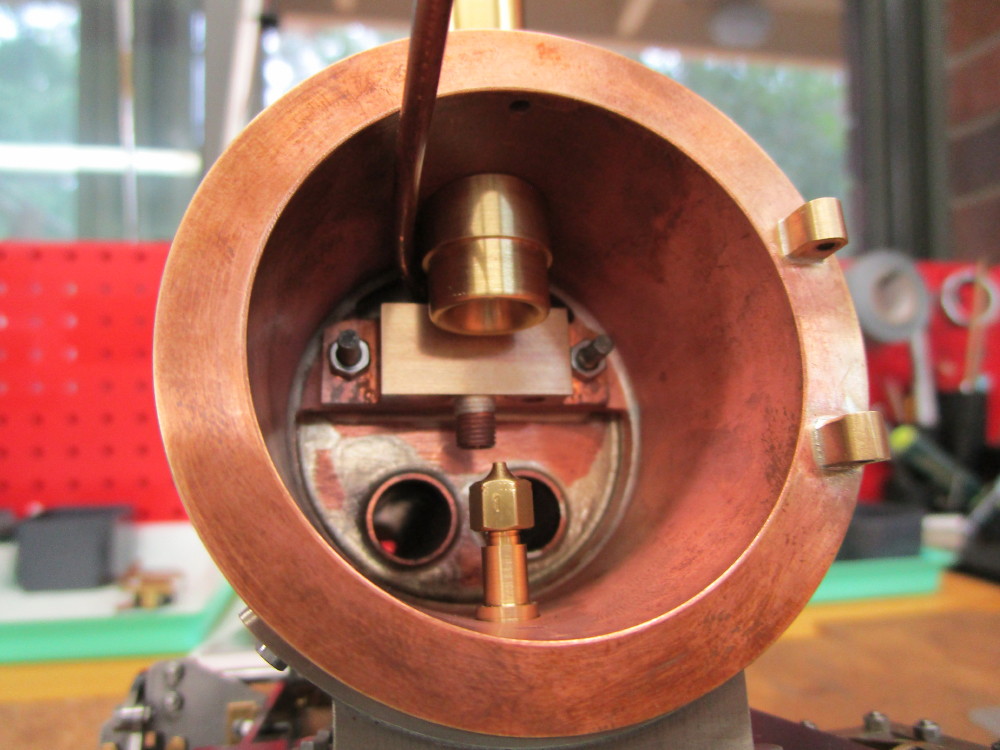

Blast pipe last night.

Re: Llewellyn Loco Works #1

Posted: Fri Nov 15, 2019 12:46 pm

by DonW

More top quality work Dazza. The Turnado system I understand to be using hand held tools which I know more as Graving. The people I know who use Graving are the 2mm finescale workers where they are making very fine cuts most of the time.

Don