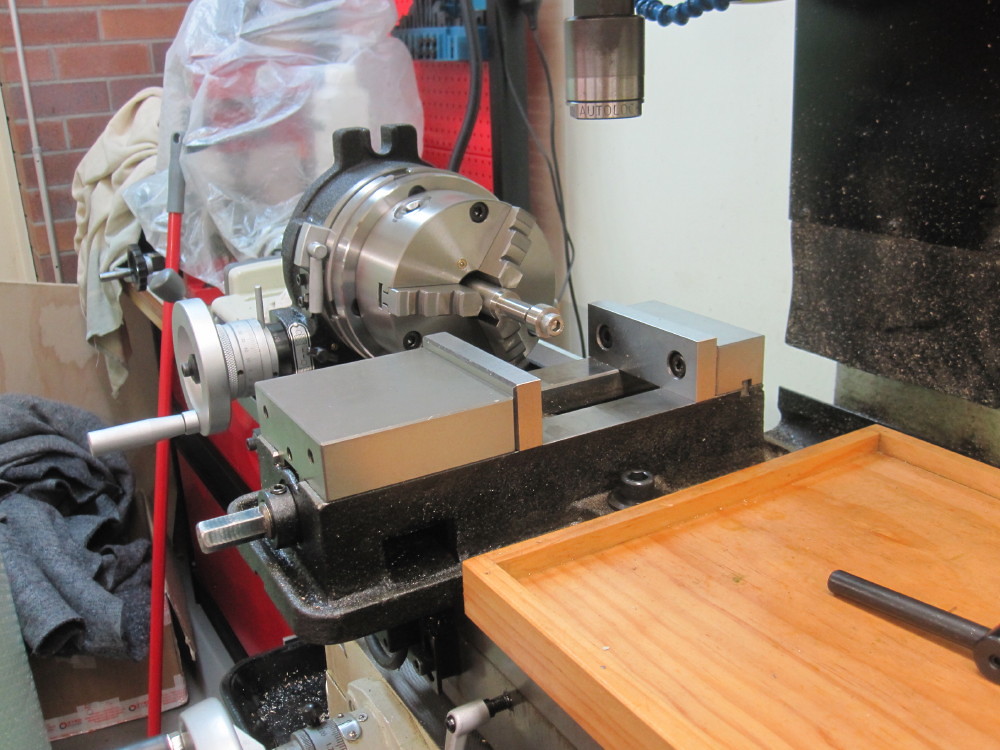

Rain all day Saturday so the civil engineering gang stayed in doors on the "POR". The

Red Room saw action for most of the day.

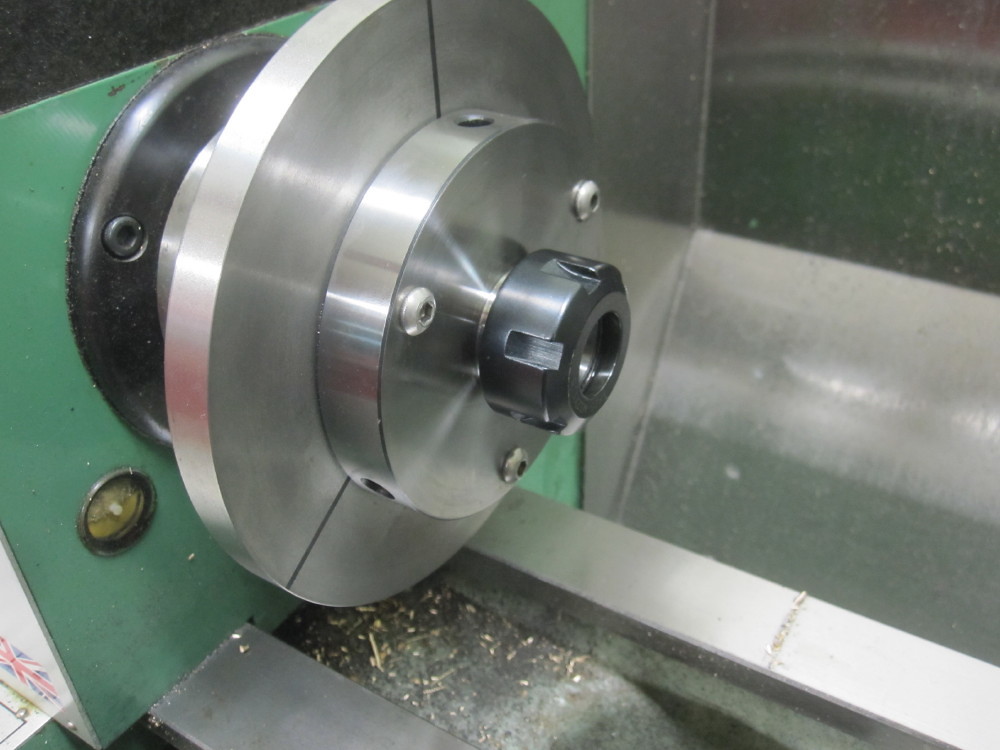

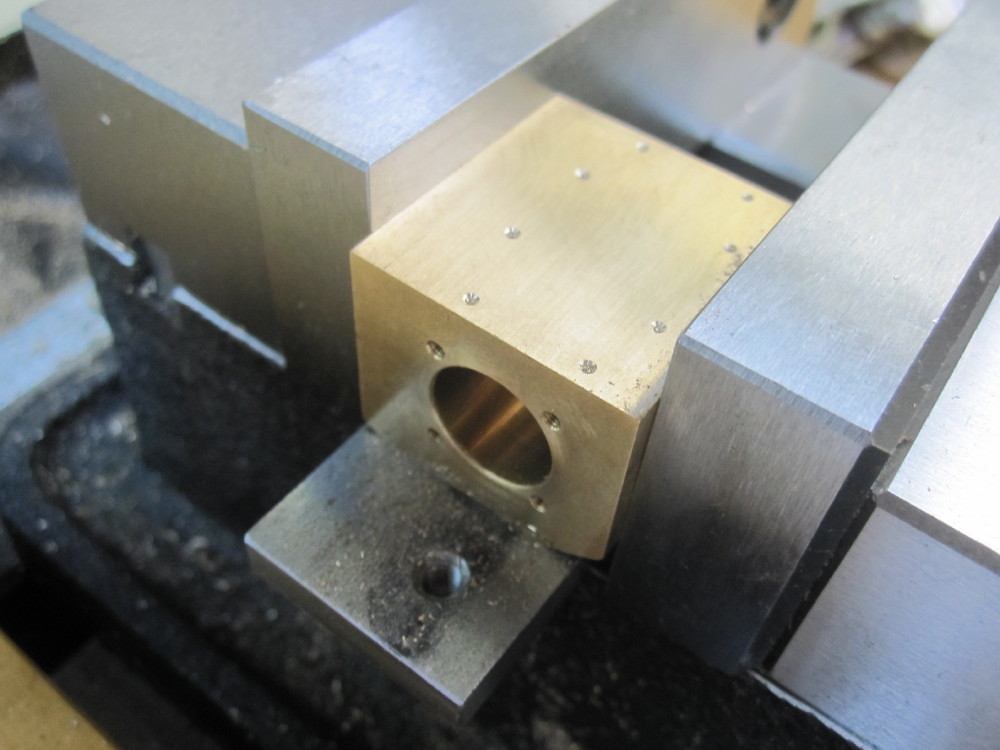

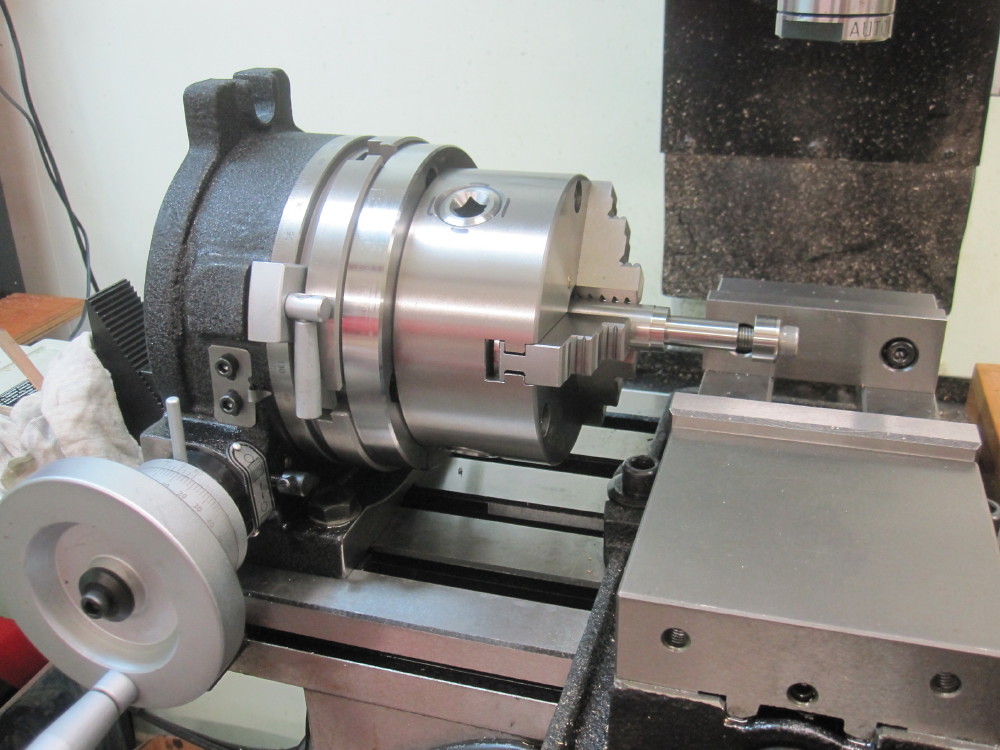

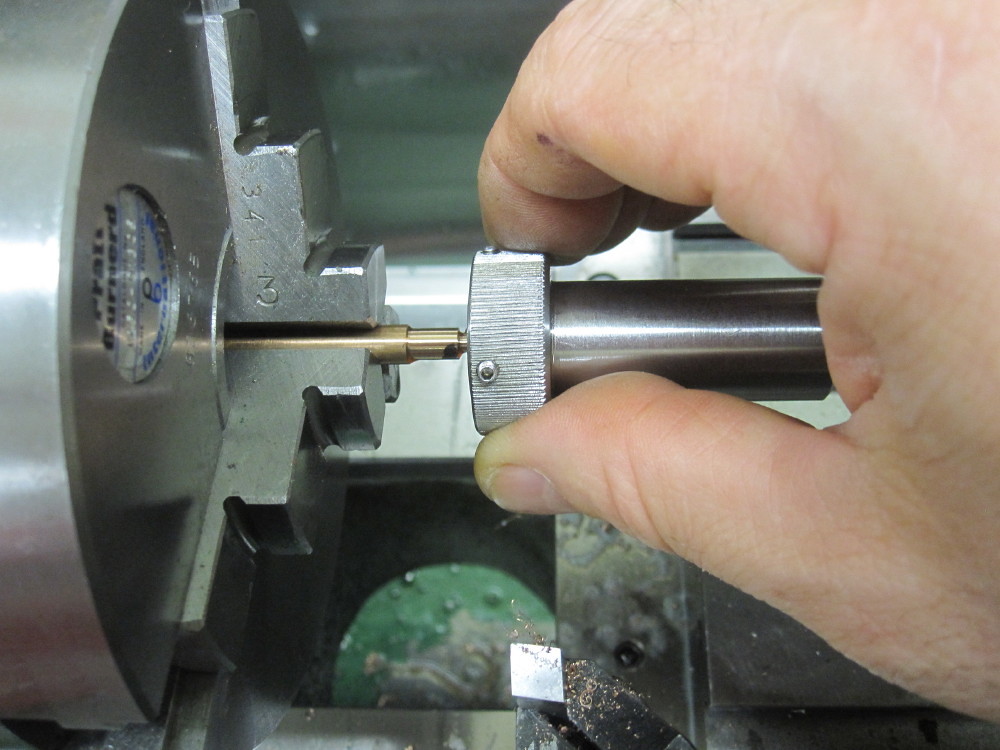

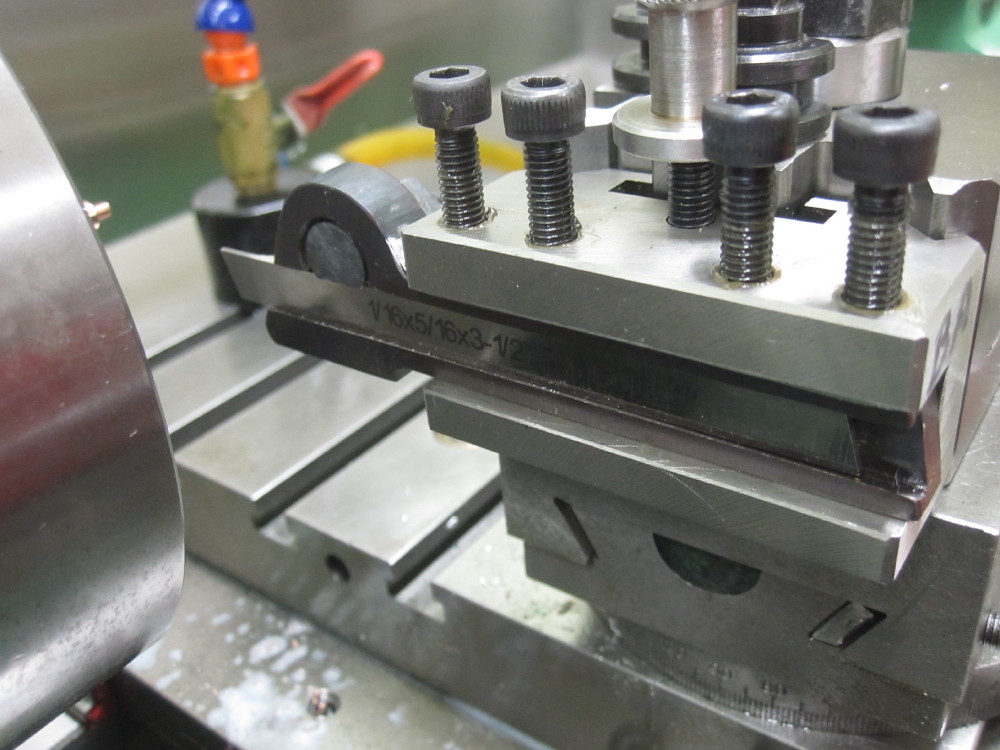

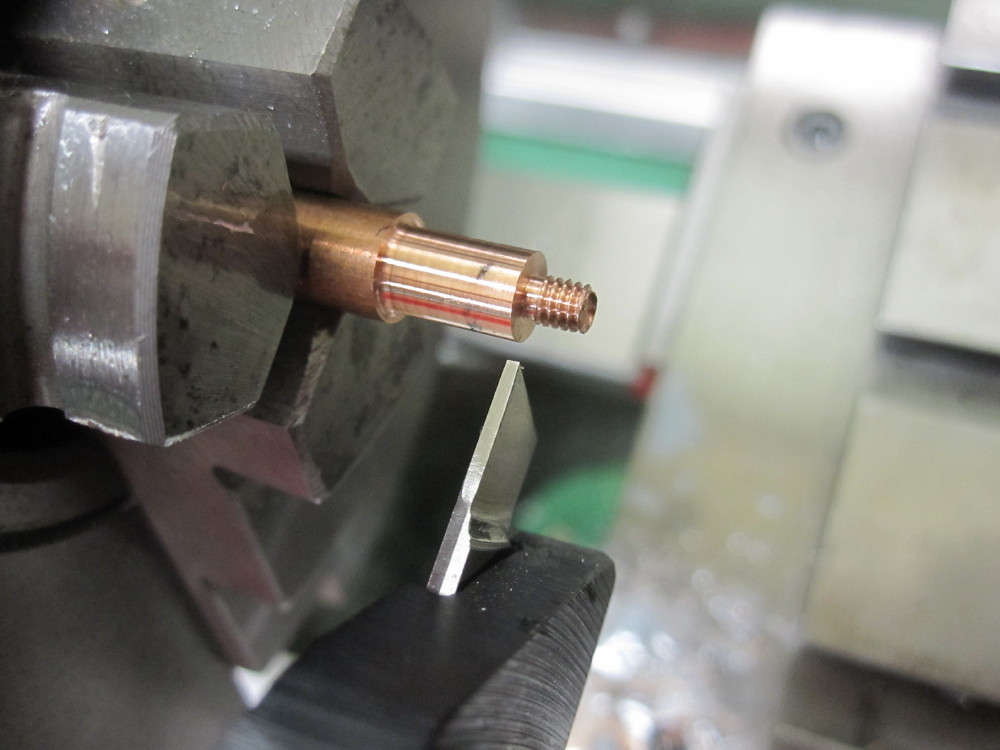

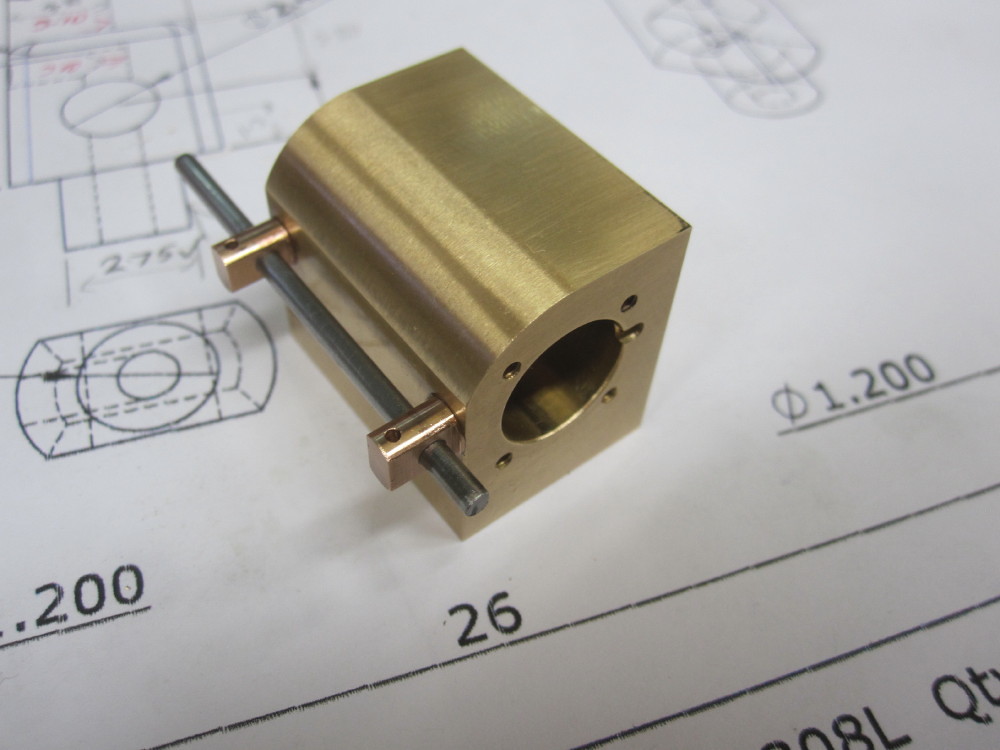

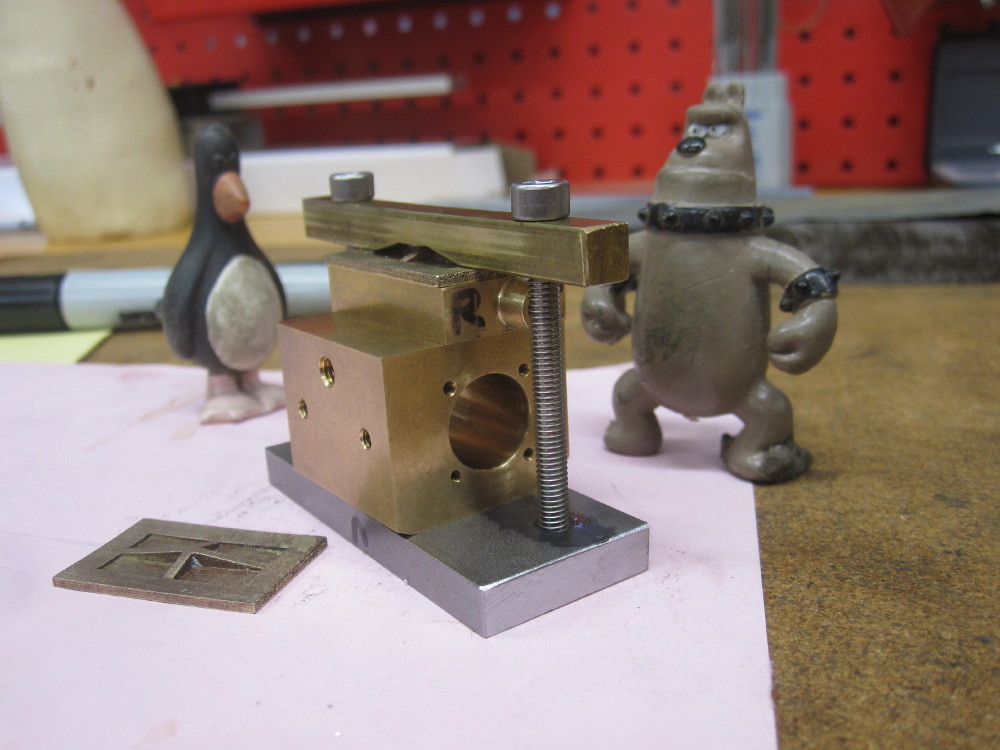

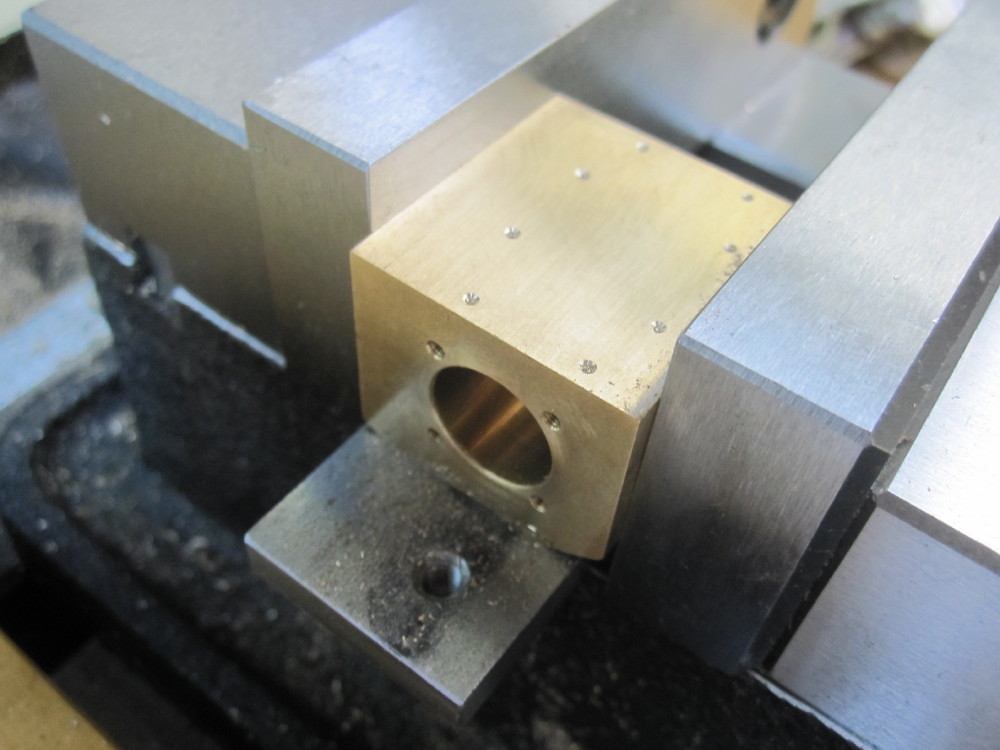

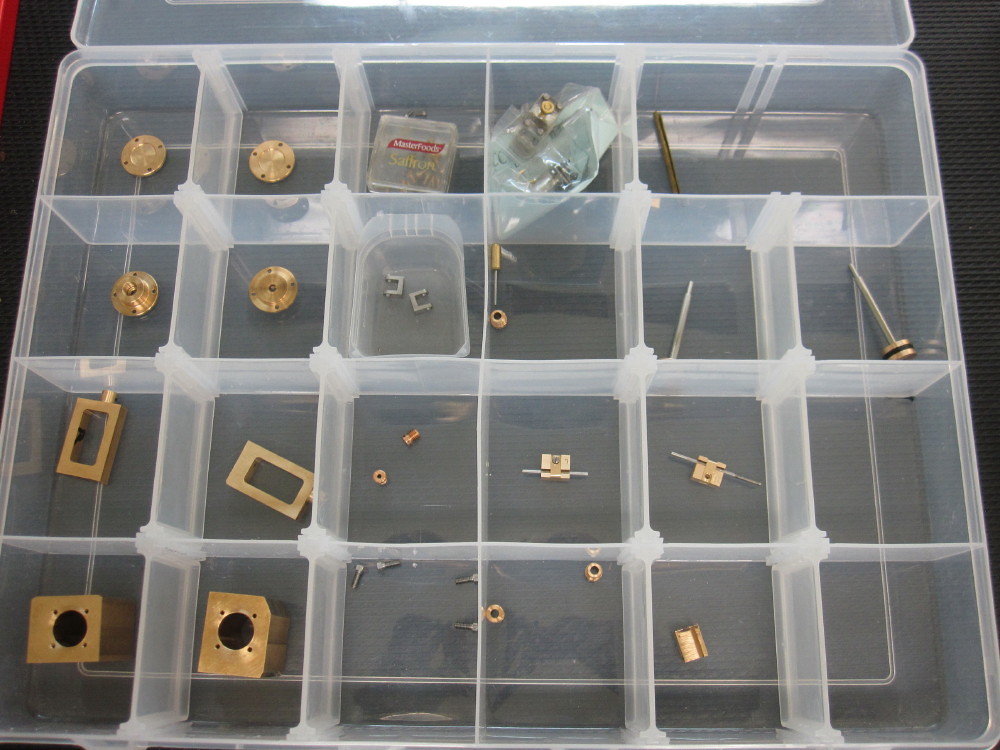

Work on the cylinders progresses.

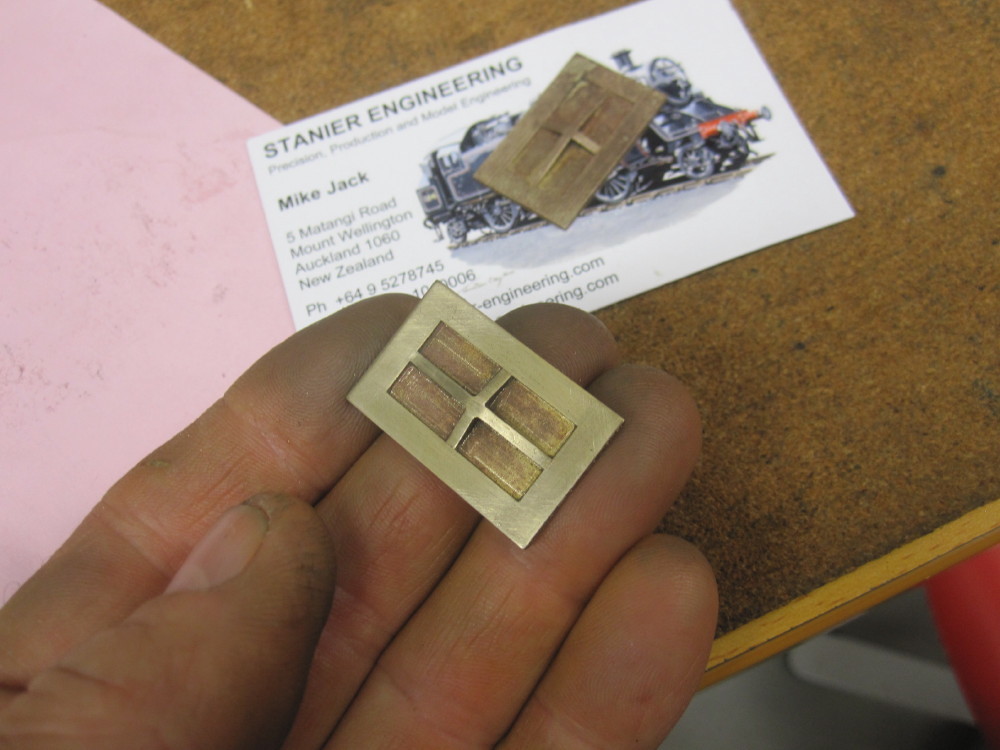

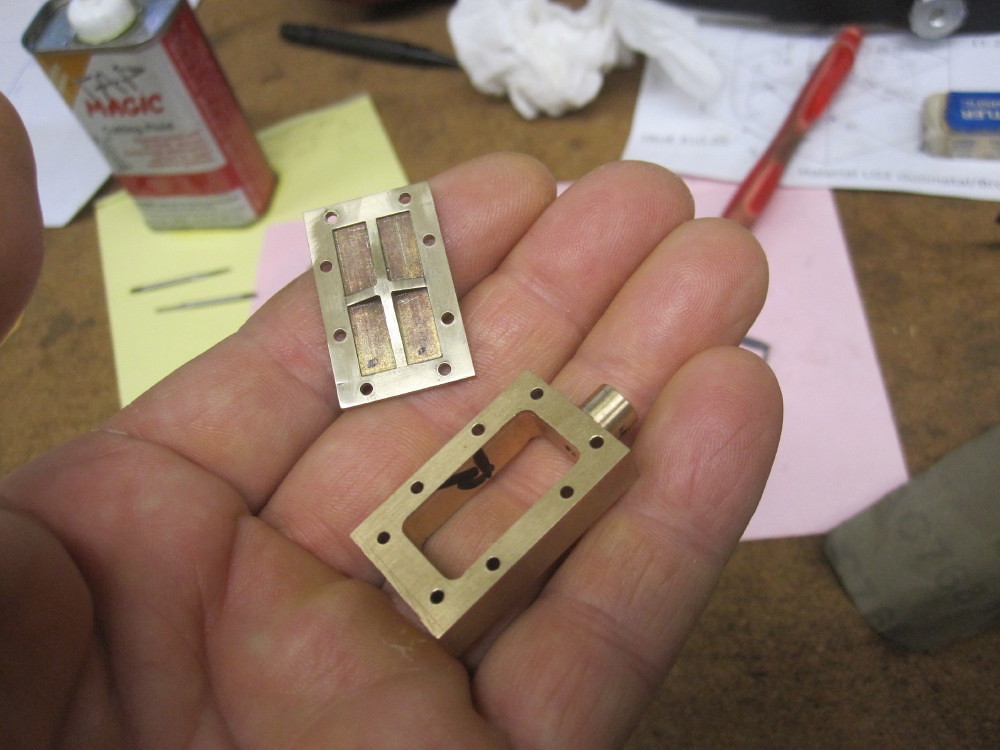

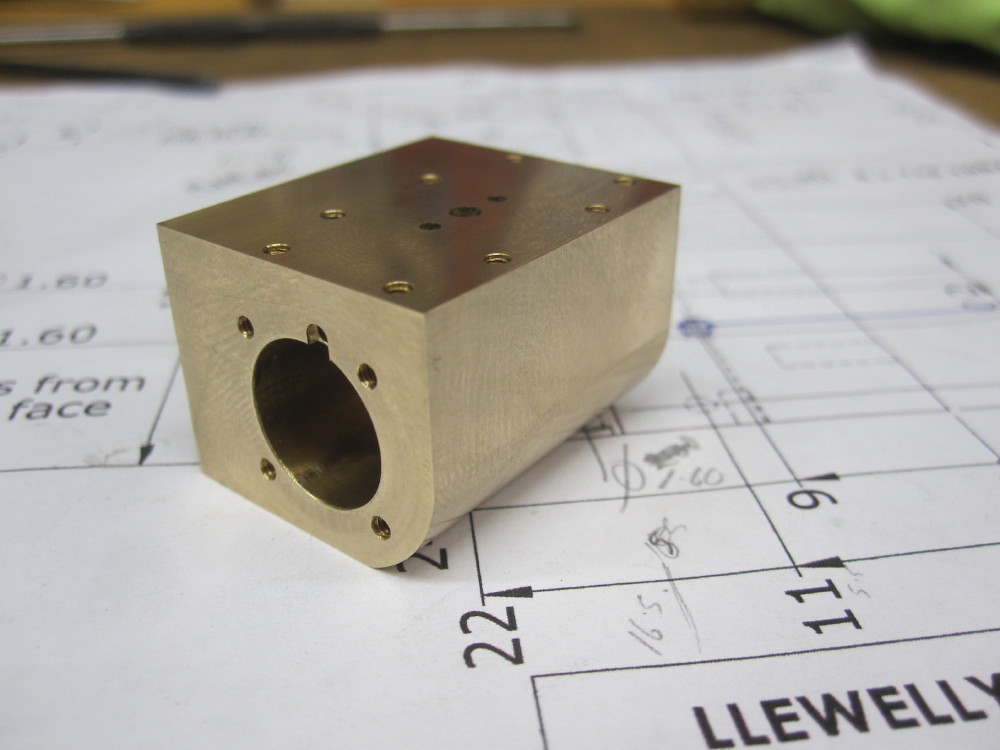

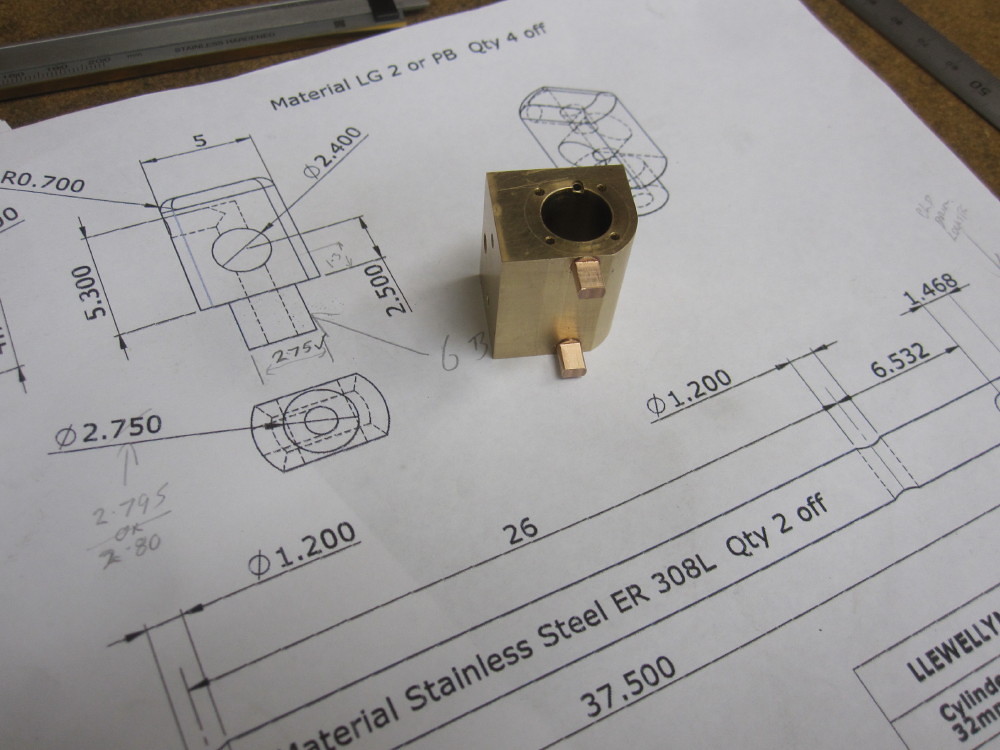

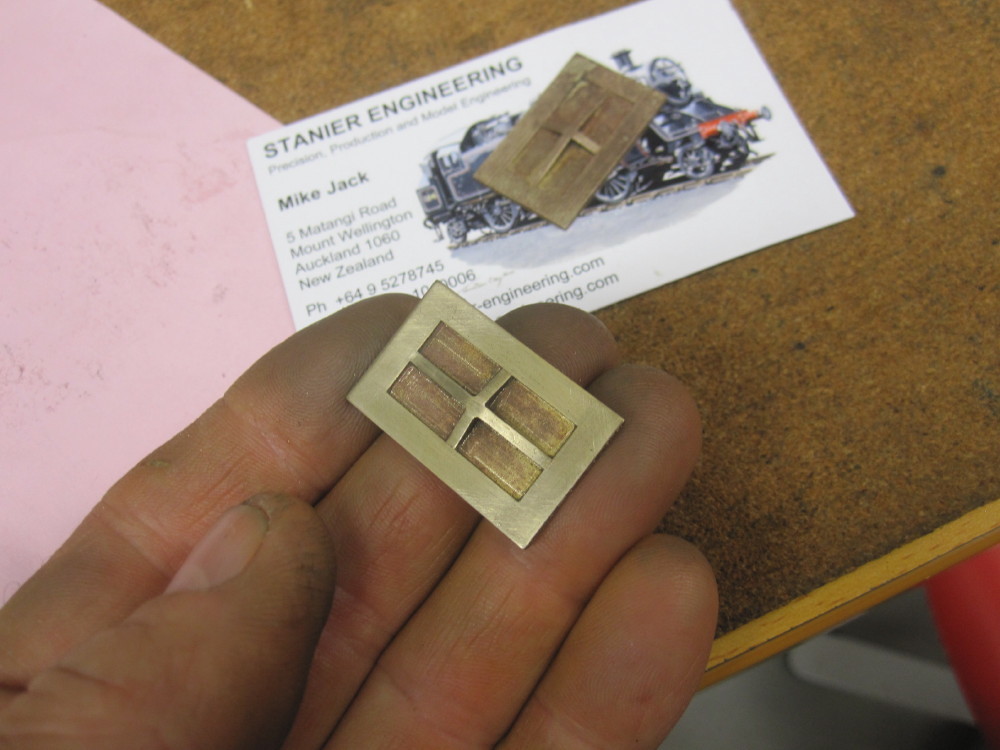

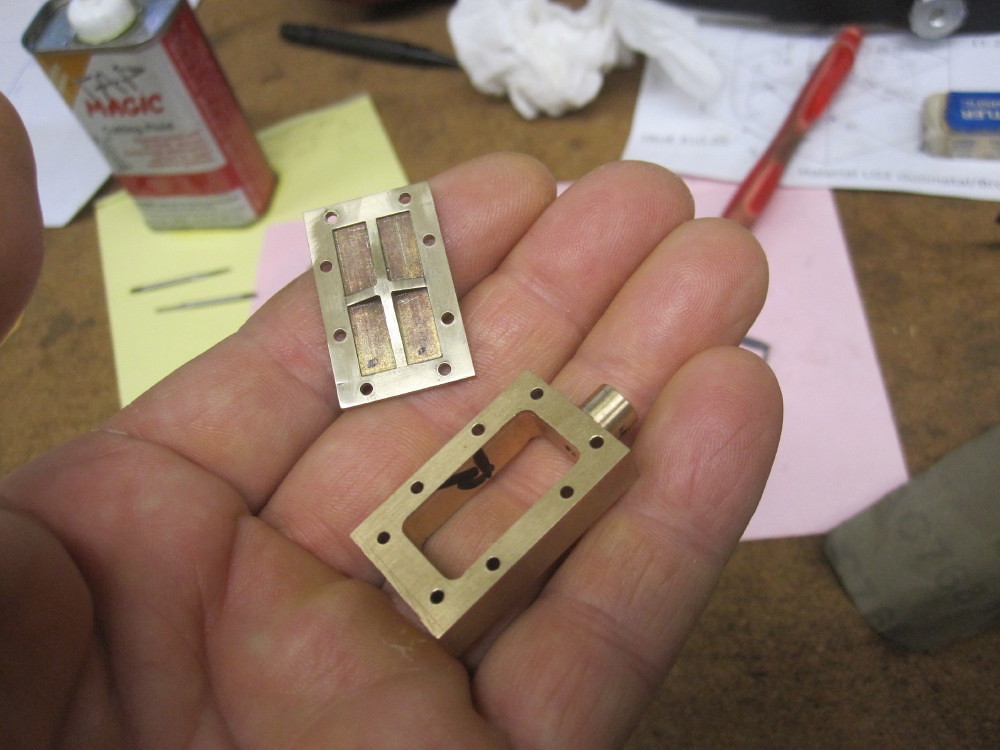

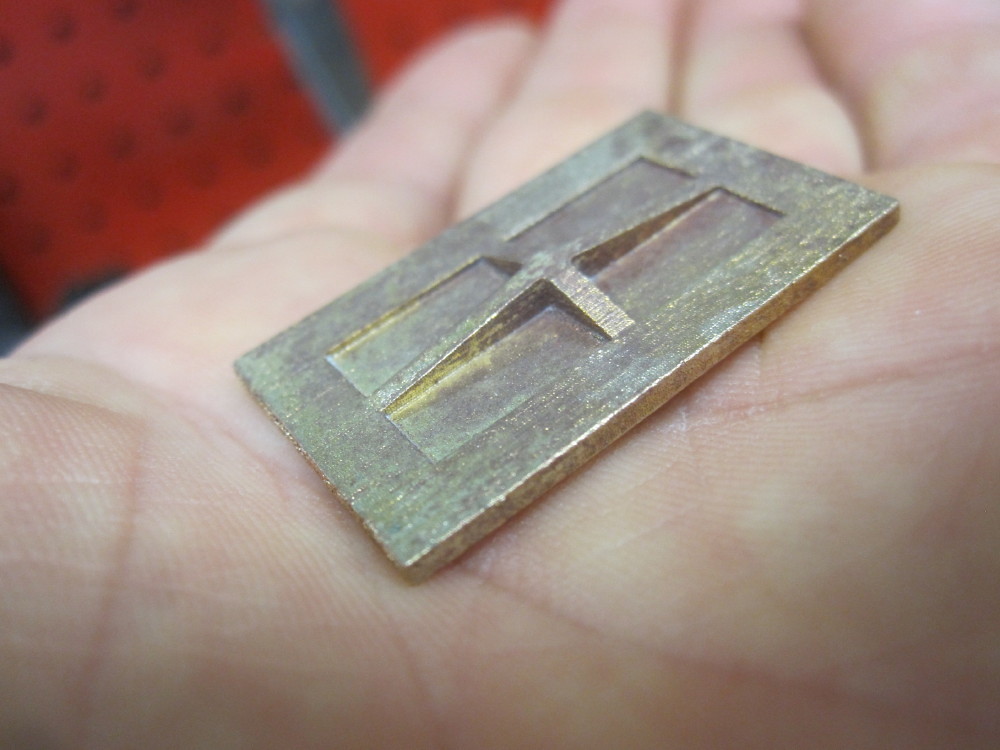

Mike Jack sent me these covers he cast in Silicon Bronze, they were off my drawings and these are the start of the education and processes of using many more castings from my drawings in the future.

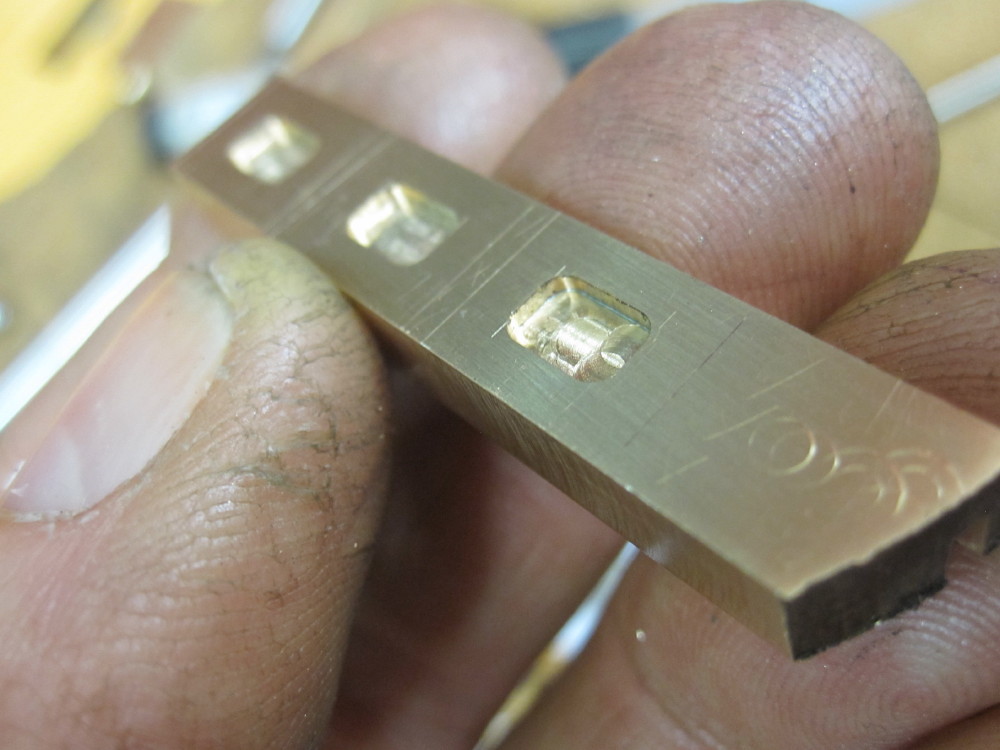

I gave them a wee bit of attention with some 600 grit

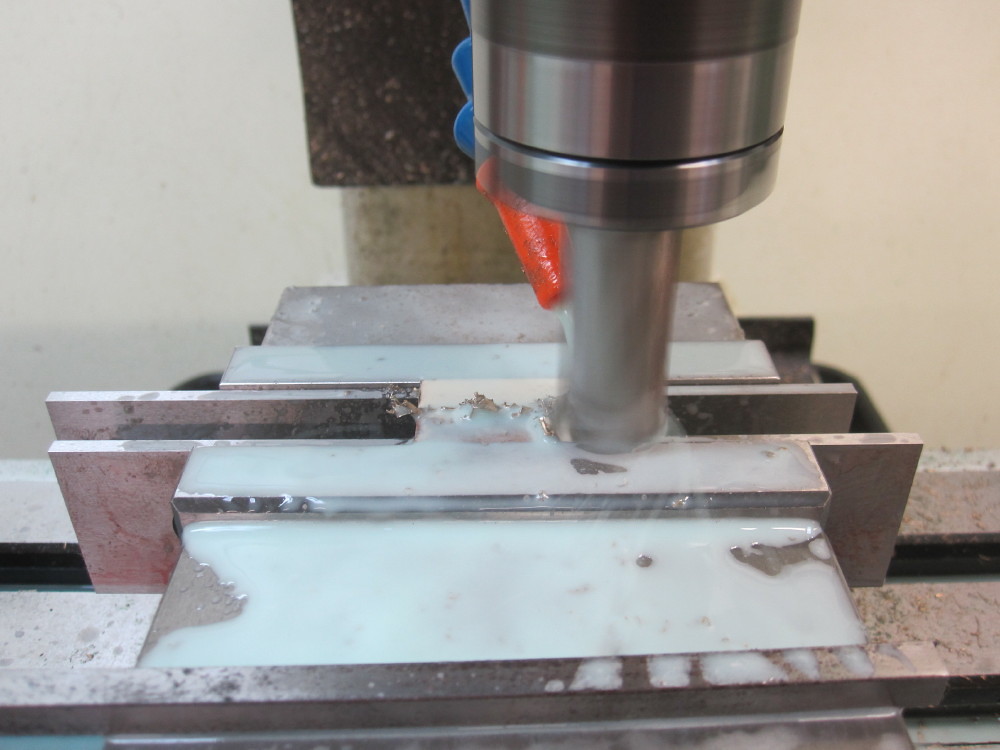

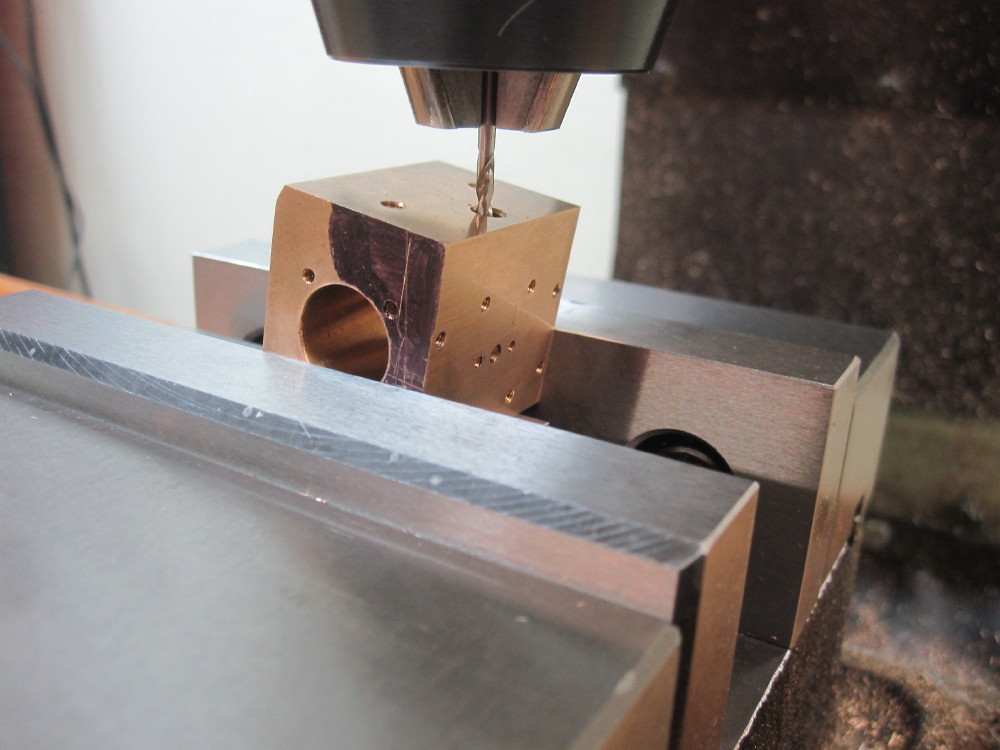

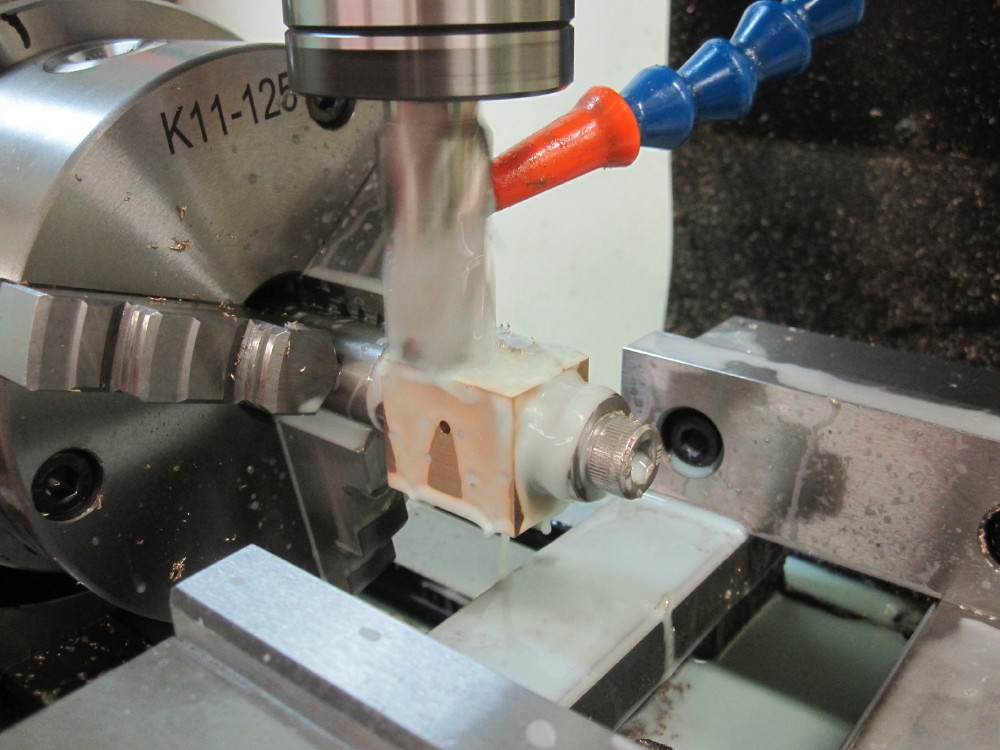

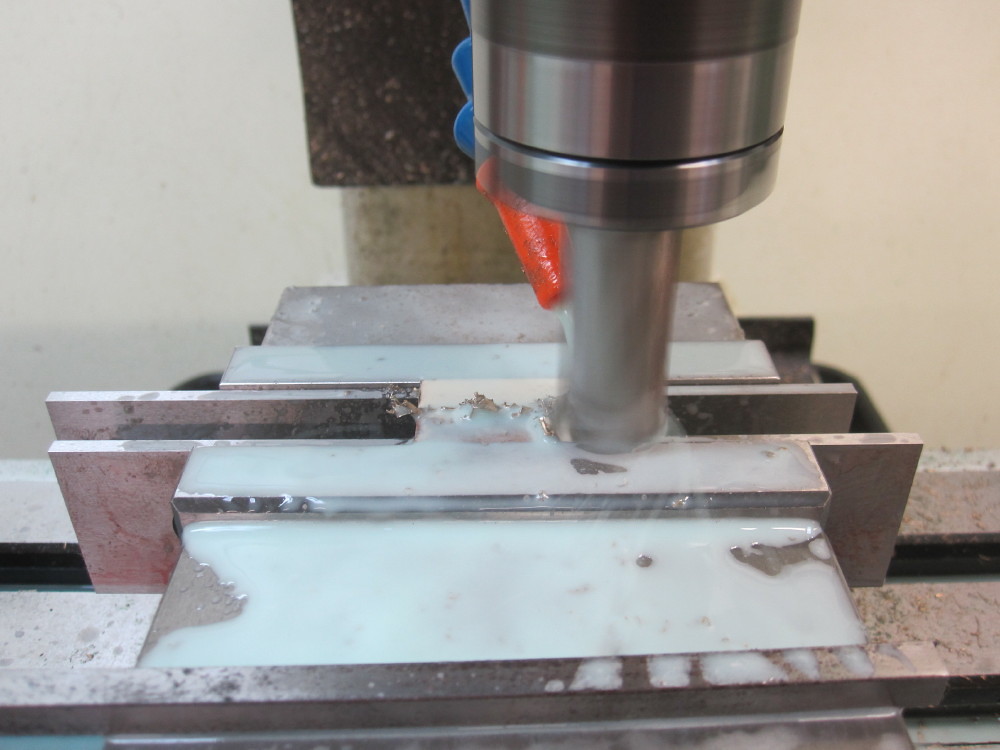

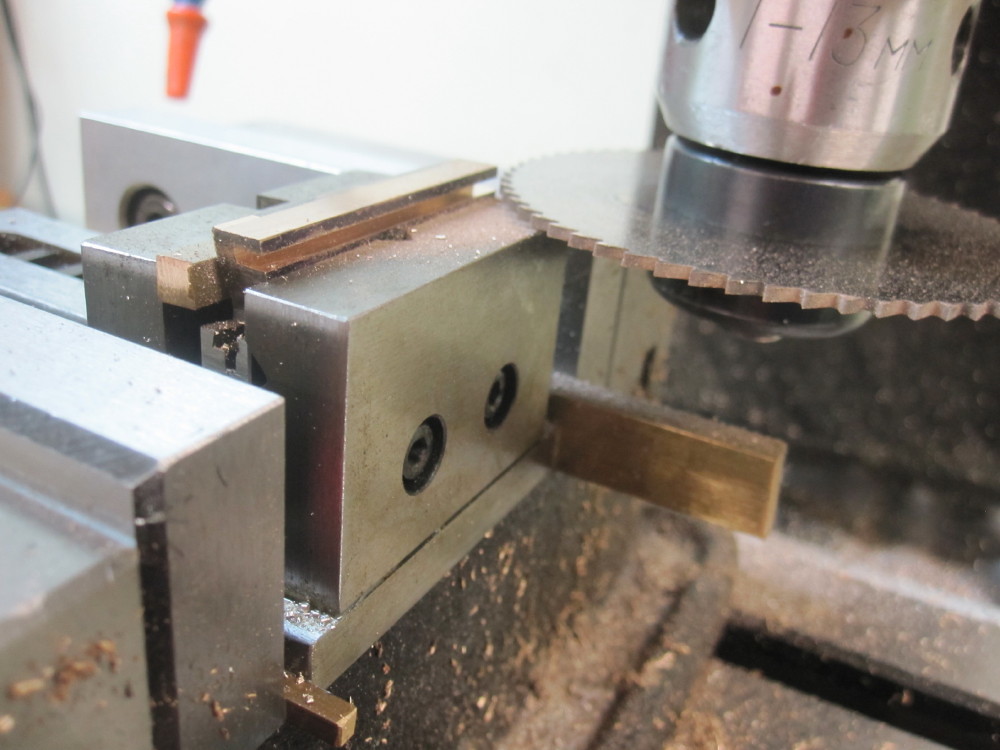

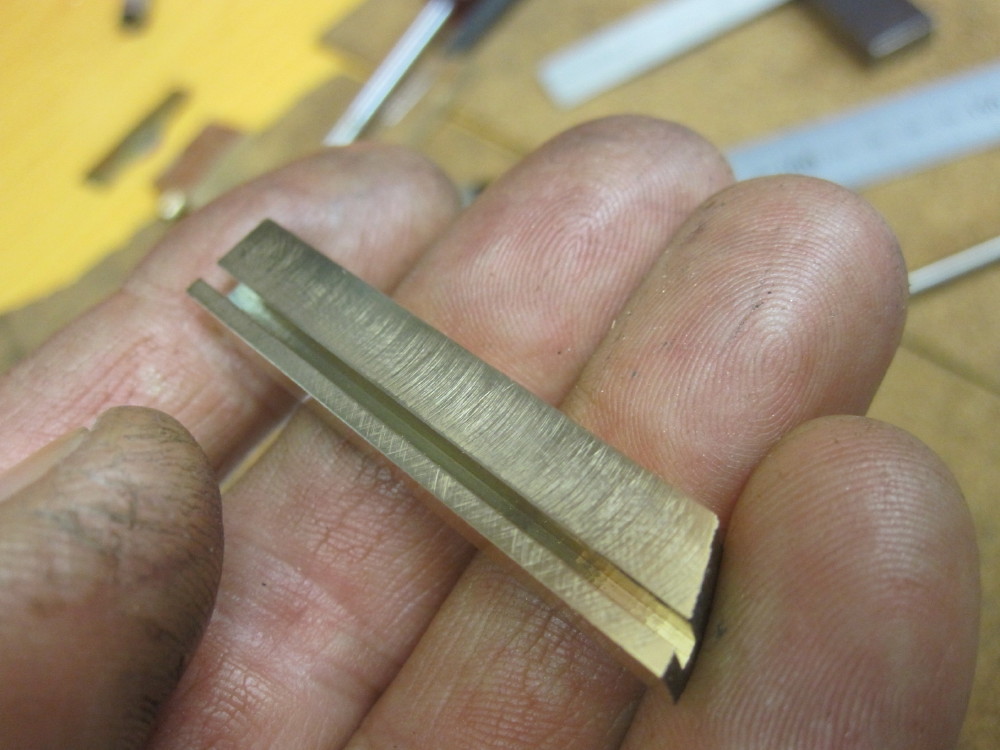

Then a wee careful mill to get a clean face.

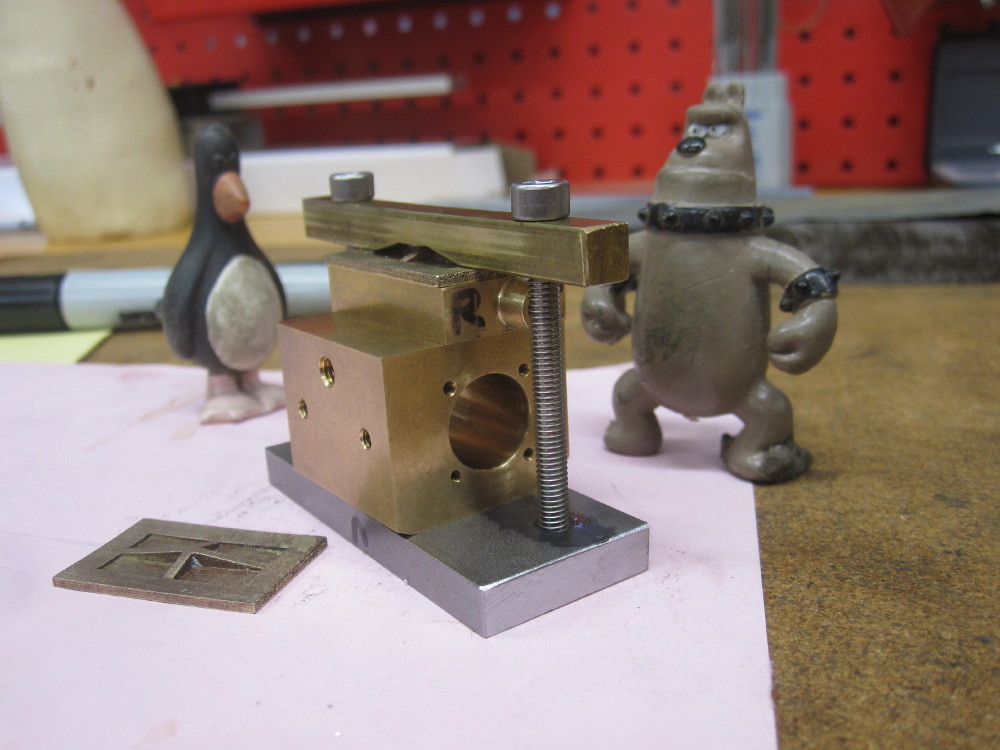

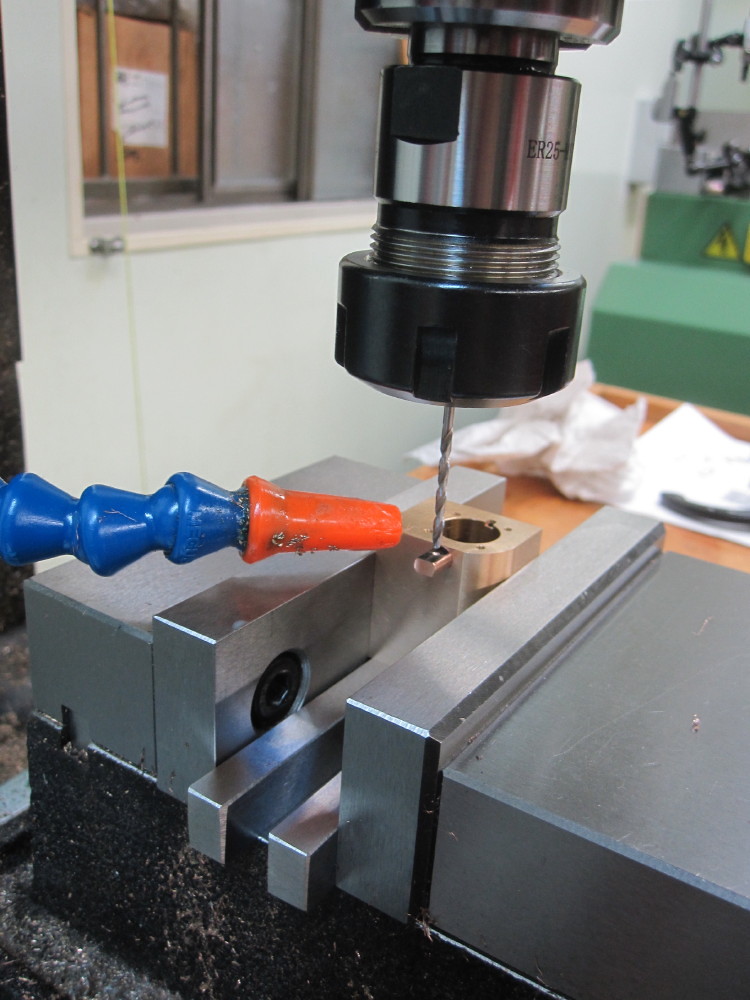

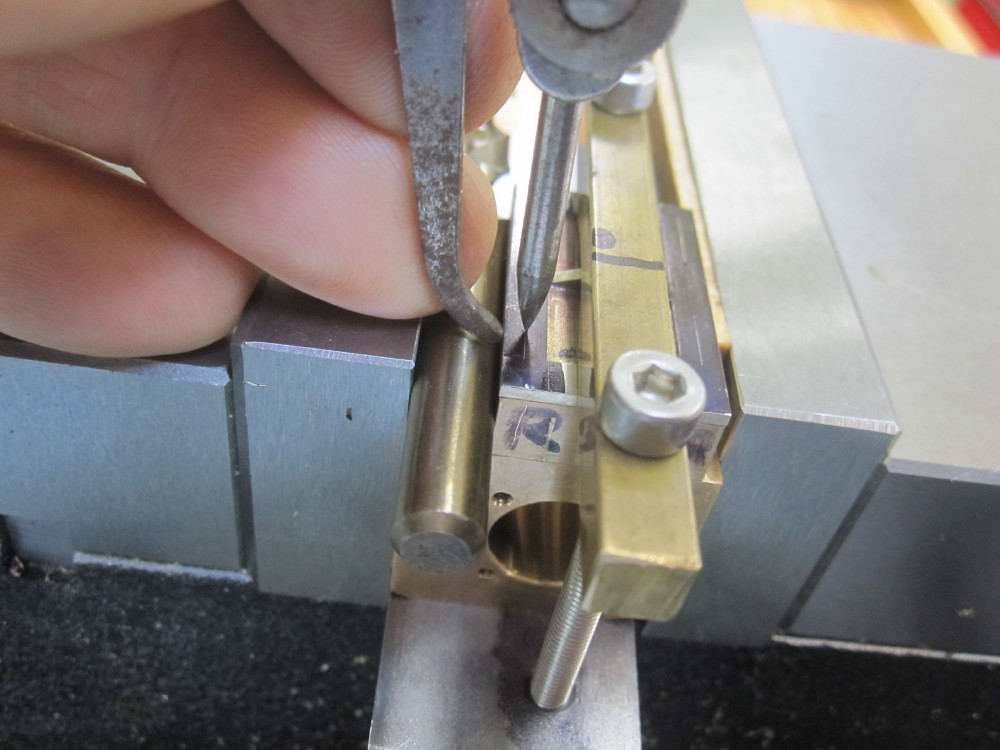

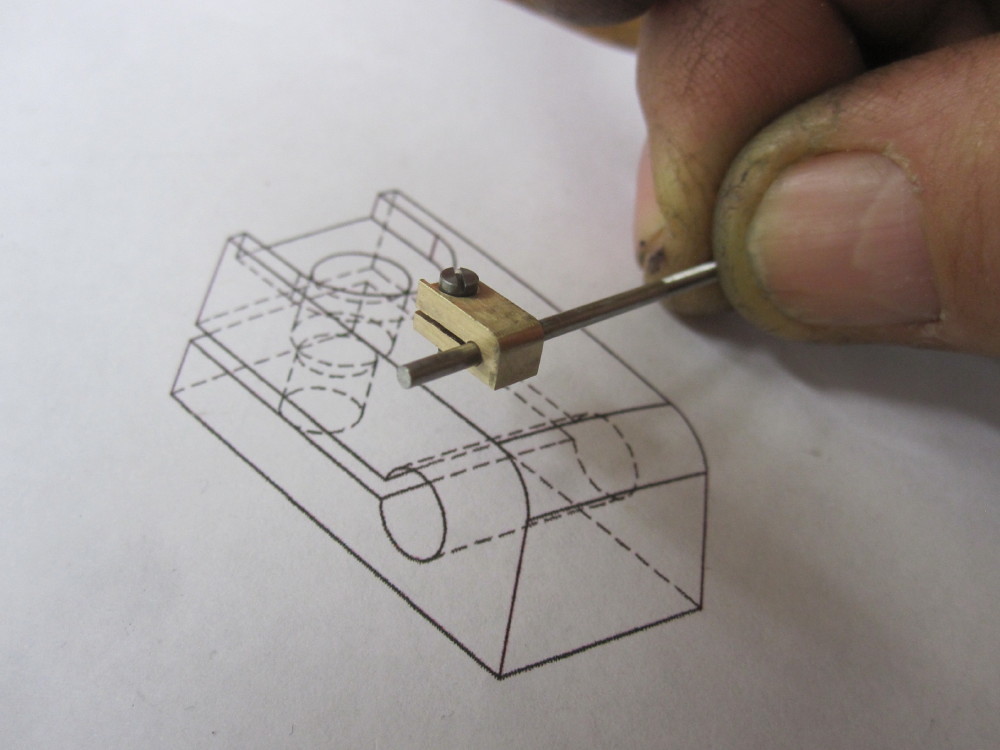

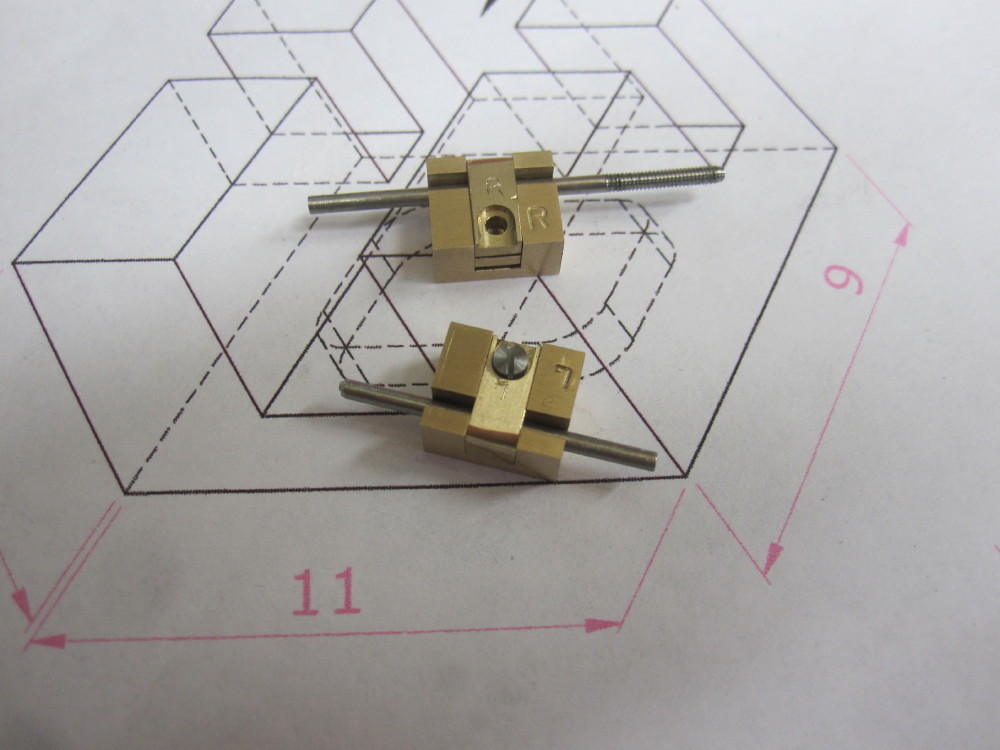

The lads, they look a bit rough and untrustworthy, but they have redeemed them selves from their past and they do good work. The air is bit blue with their language when things do not go quiet right but they figured out a little jiggy for the cover and chest drilling. (jiggy is a Dazza technical term)

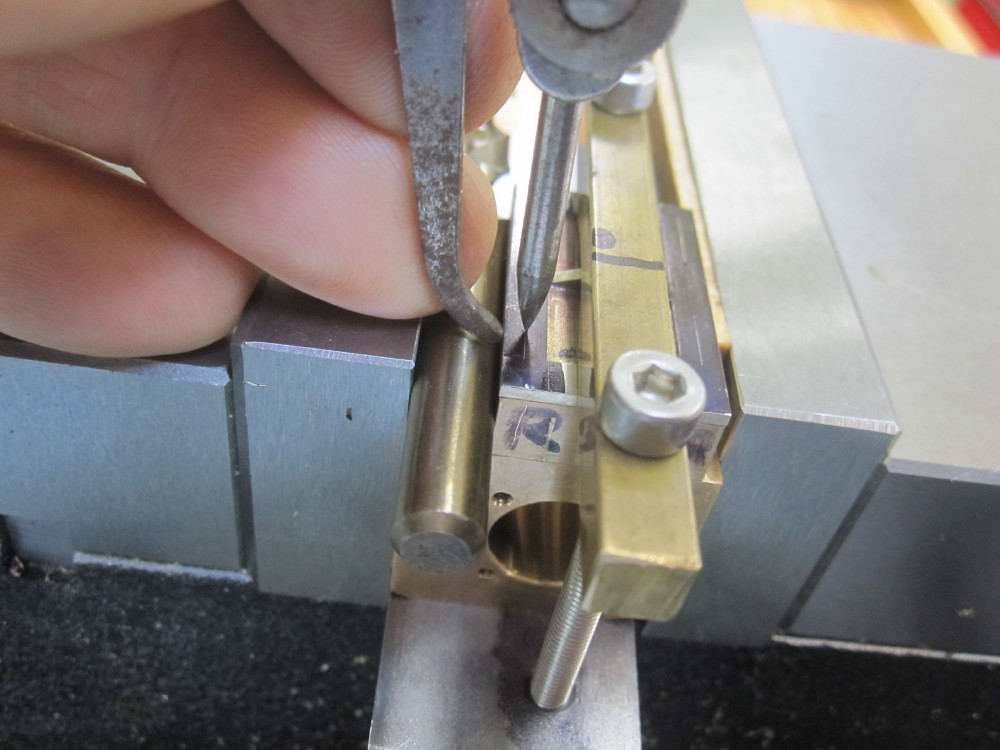

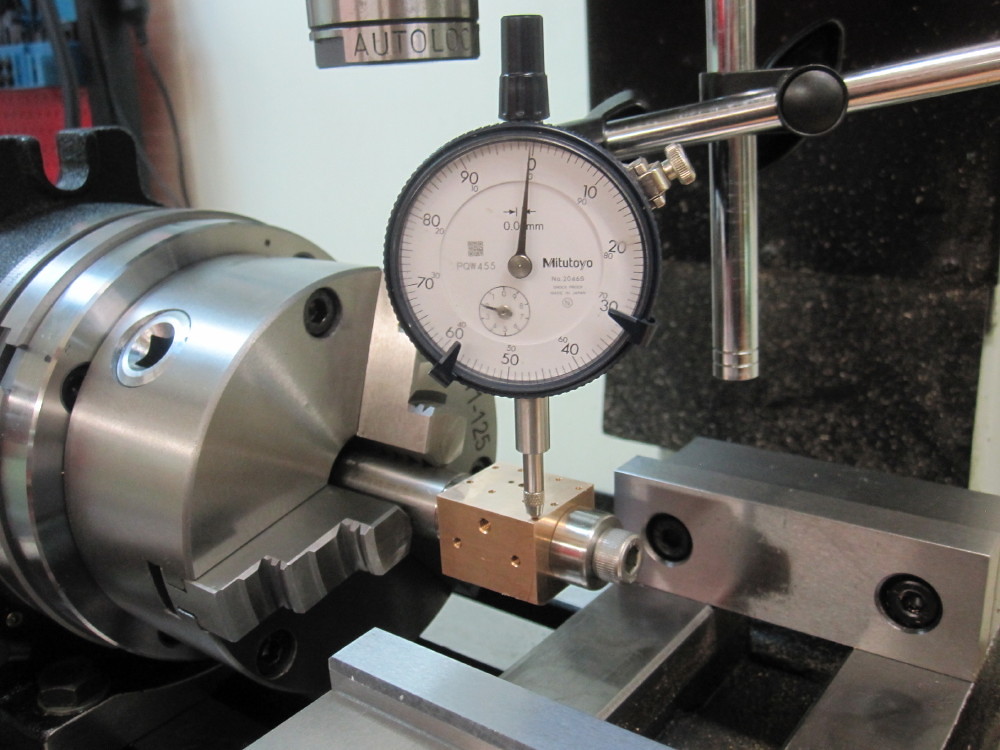

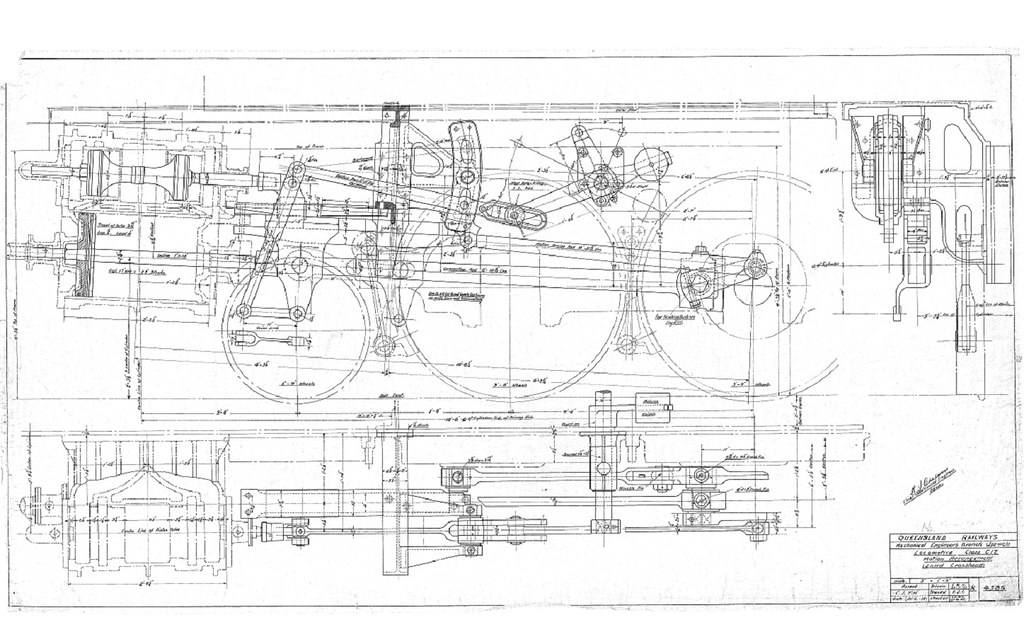

The 7.20mm drill is align the steam chest to the cylinder and the frame mounting face. (I like using a datum) Even though I have DRO I carefully marked out the sanity lines, just be to be sure (I am glad I did)

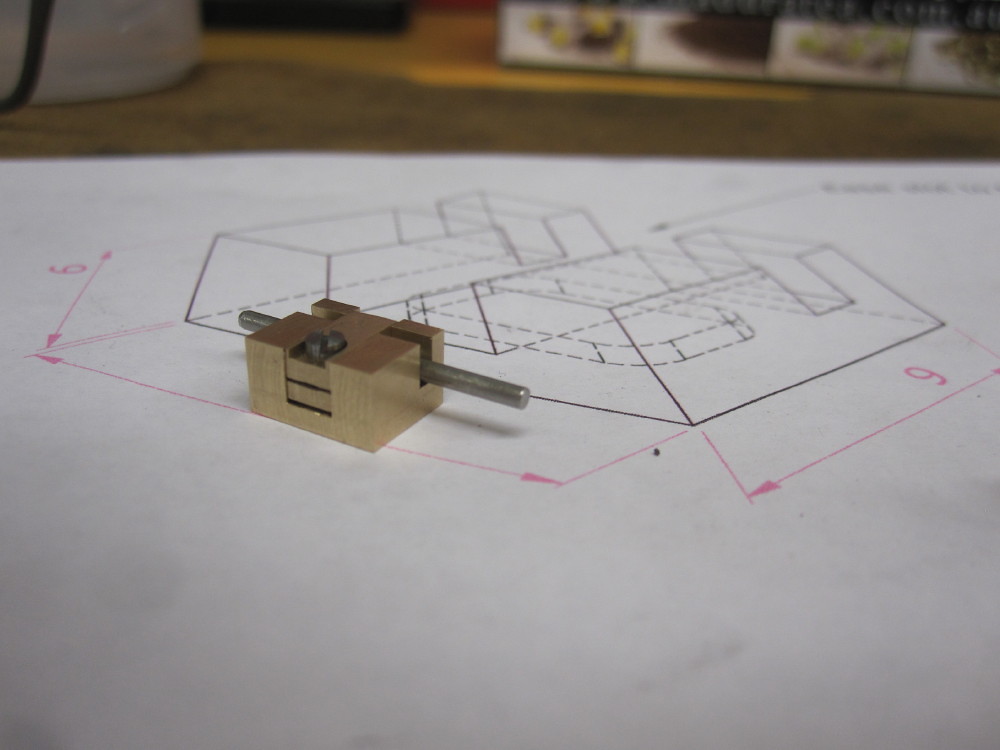

The clamp on the jig is removed and the chest and cover removed but the clever bit is that the cylinder stays held in the vice and the location for the X= 0 and Y=0 stays undisturbed.

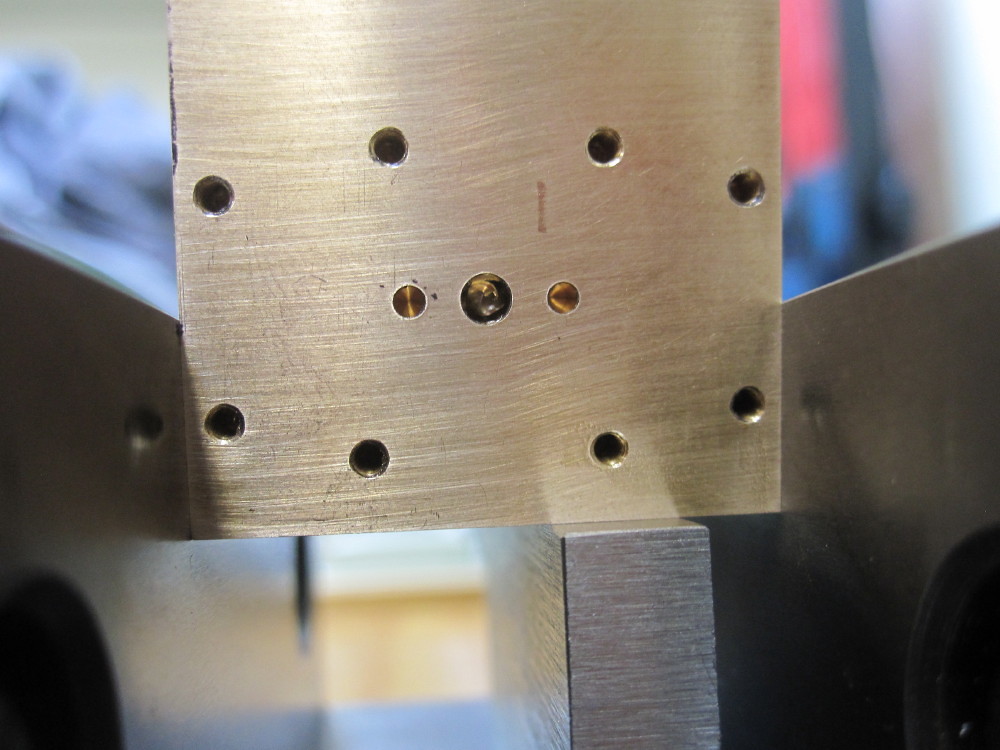

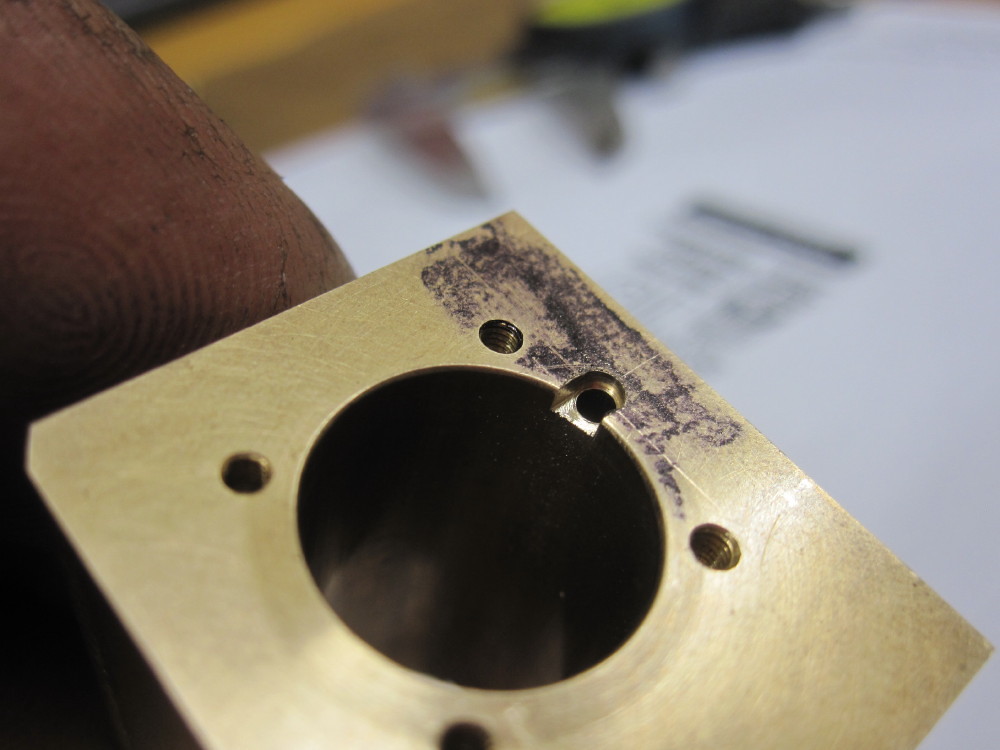

Done and happy. You may see that one hole for the 10BA studd to pass through is in a different location, that is give clearance for the inlet to the chest. A detail that is visible on close inspection not noted or dimensioned in the Steam Trains In Your Garden Book's drawings or text.

When the next adventure in the Red Room kicks off I will use the DRO to pick up the holes to be drilled 3.50mm deep and taped 10BA for the studs. Have I said recently how much I like DRO on the mill/drill ?

With my 32mm loco build I just save things into a folder and when motivated I load it to my flickr site.

With my 32mm loco build I just save things into a folder and when motivated I load it to my flickr site.