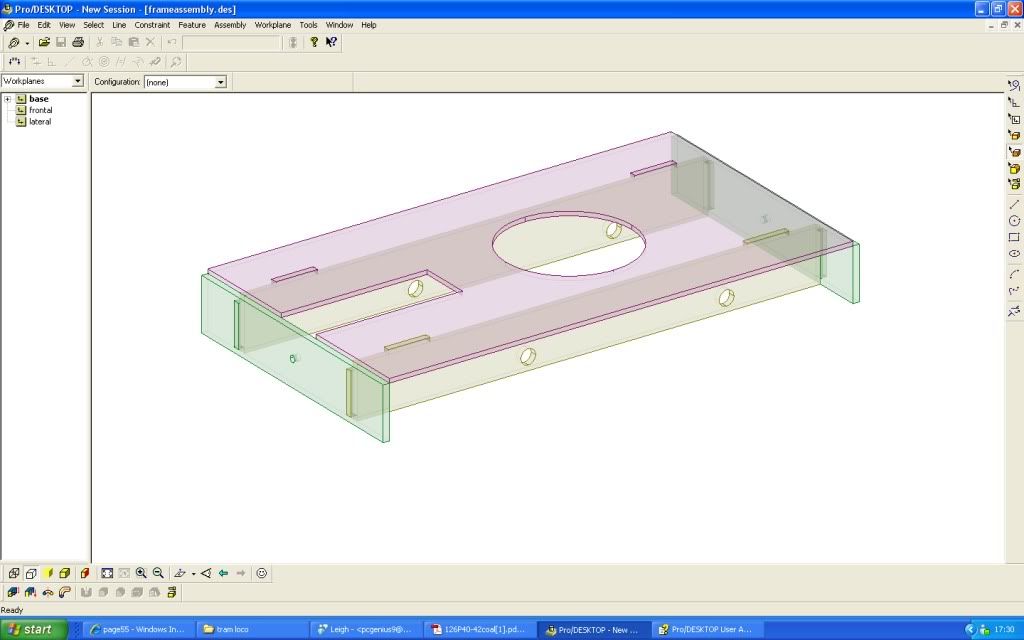

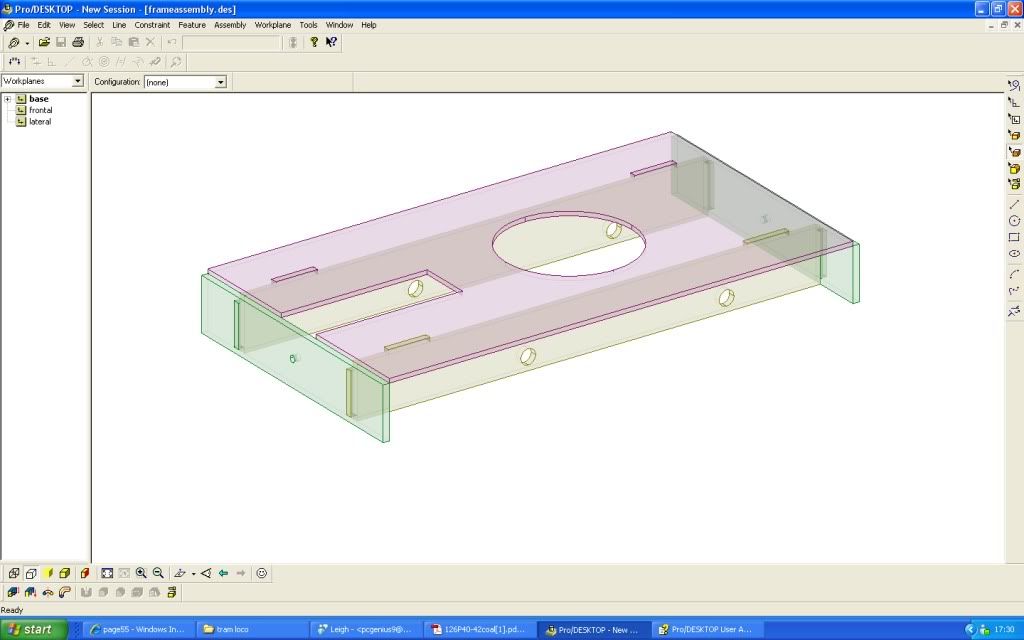

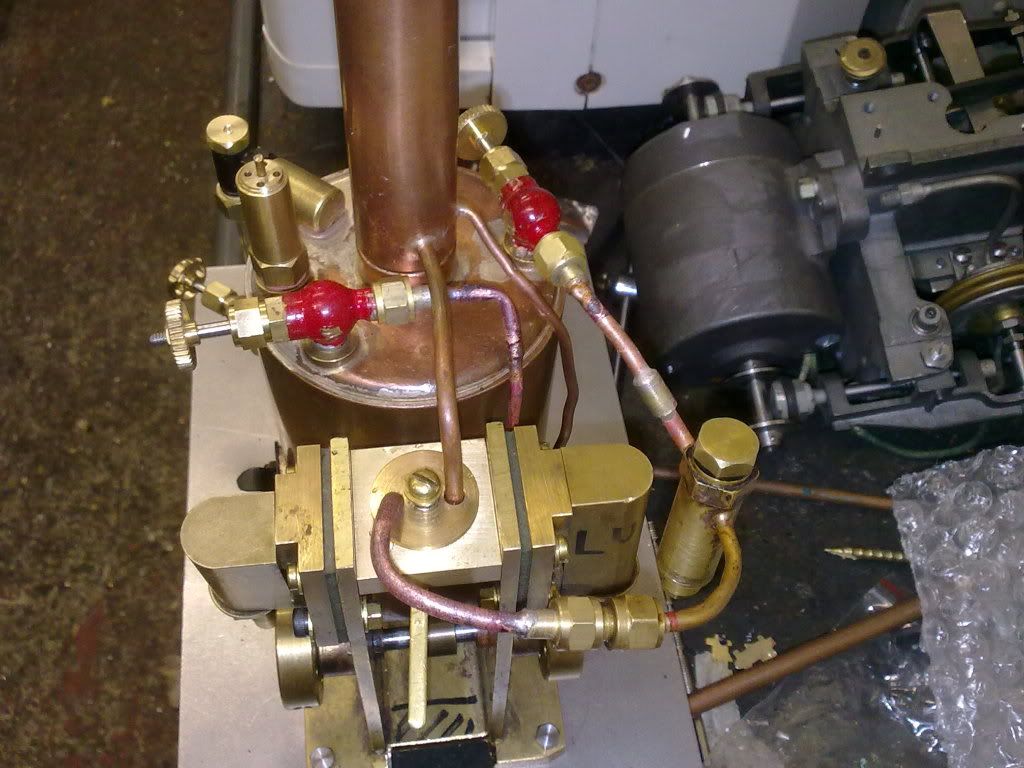

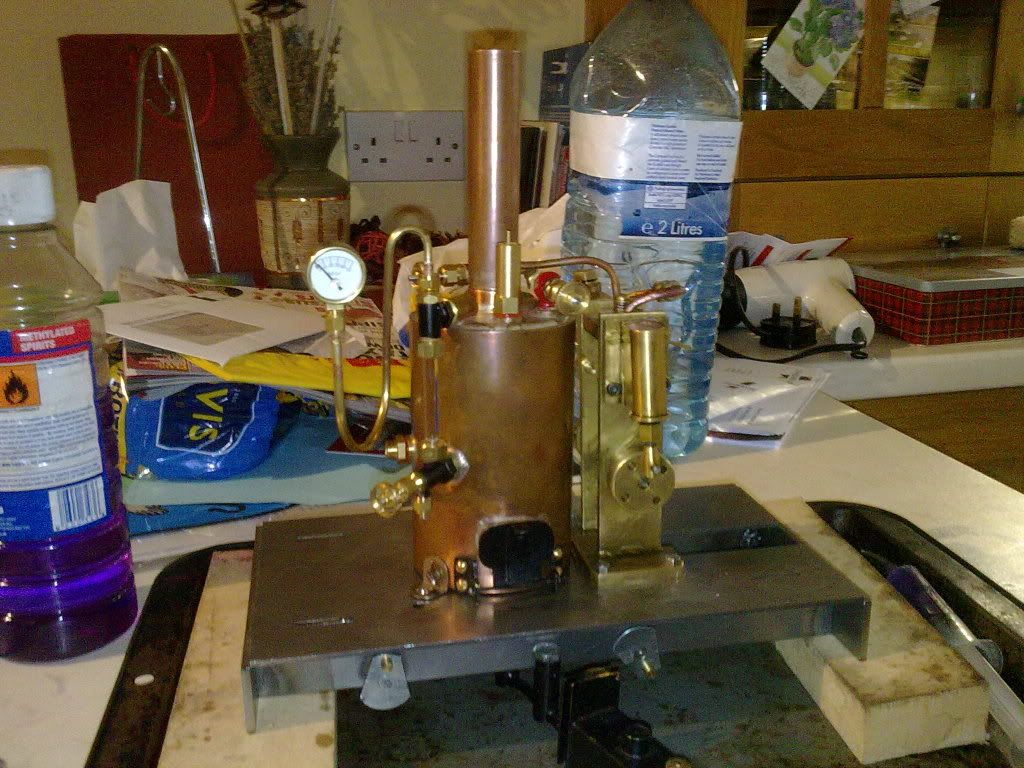

I like the boiler. I've built gas fired vertical boilers before, but would like to try my hand at a coal fired one. How and where does the blower pipe from the exhaust fit? How many fire tubes are there and what diameters, please? Was it built to your design, or a published one by somebody else? Do any drawings exist and if so would it be possible to have a copy, please?bessytractor wrote:I've finally got this project in hand. Basically its a coal fired steam tram with a double acting twin cylinder ossy engine and a vertical boiler. I built a chassis out of K&S brass but I kept changing ideas as to how to do it, by the time I finished it looked dreadful so I've put it to one side for something else and I have CAD'd up a tab and slot chassis for my favourite laser cutter to get cut for me. The boiler has been built (not by me I should point out, its far too good a job for that!) and the engine exists. All the chassis will require is the holes drilling and then silver soldering together and some axle bushes made up, then it will be a very short step away from being a working engine. I've got the necessary Essel wheels and flycranks already.

I bet you're not happy with that.bessytractor wrote:FOR PETE'S SAKE

I've just recieved the laser cut chassis parts and the buffer beams are the only correct bits on it. The footplate and main frames are 25% odd too small! This renders them completely useless. I've sent a less than impressed email.

I shan't be selling it, its a project I really want to finish. Btw you asked about the boiler, its basically this one, all dimensions are in the article:Mr ACME wrote:I bet you're not happy with that.bessytractor wrote:FOR PETE'S SAKE

I've just recieved the laser cut chassis parts and the buffer beams are the only correct bits on it. The footplate and main frames are 25% odd too small! This renders them completely useless. I've sent a less than impressed email.

BTW if you feel the need at any time to sell it on, please let me know.

Best

Mike Ousby

Thanks for your help.bessytractor wrote:I shan't be selling it, its a project I really want to finish. Btw you asked about the boiler, its basically this one, all dimensions are in the article:Mr ACME wrote:I bet you're not happy with that.bessytractor wrote:FOR PETE'S SAKE

I've just recieved the laser cut chassis parts and the buffer beams are the only correct bits on it. The footplate and main frames are 25% odd too small! This renders them completely useless. I've sent a less than impressed email.

BTW if you feel the need at any time to sell it on, please let me know.

Best

Mike Ousby

http://www.16mm.org.uk/newsite/publicat ... 42coal.pdf

its been modded a touch. For example the valve bushes are now in the top of the boiler instead of the barrel, as this affords a touch more water space, which is a bit important on a boiler this size.

Errrr... no. It will probably get worse. As SirH suggests, some PTFE tape or a fibre washer will sort it out.bessytractor:44969 wrote:well its literally the tiniest of drips, I suspect it will take up under steam.

luckily the gauge came with those Dave, but thanks anyway. The leak was where the fitting screws into the boiler but its all gravy now.DaveWatkins:45071 wrote:A slice of silicon rubber tube makes a good seal for water gauge glass. Slip a length of silicon rubber tube over an odmment of of bar. Hold the bar in lathe chuck and cut off neat rings with a sharp knife as the bar spins.

Users browsing this forum: No registered users and 4 guests